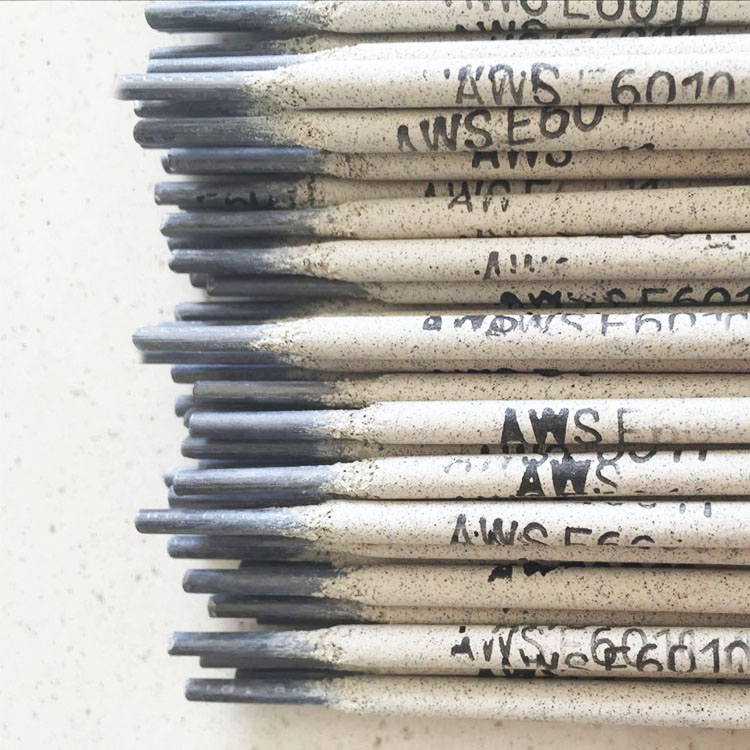

Leading Manufacturer of Stainless Steel Welding Rods in China for Quality and Reliability

The Rise of China as a Leading Manufacturer of Stainless Steel Welding Rods

In recent years, China has emerged as a powerhouse in the manufacturing of stainless steel welding rods. This remarkable growth can be attributed to several factors, including advances in technology, a robust supply chain, and a talented workforce, which together have enabled the country to meet the increasing global demand for high-quality welding materials.

Technological Advancements

One of the primary reasons for China’s ascent as a leading manufacturer of stainless steel welding rods is the investment in advanced manufacturing technologies. Chinese companies have embraced state-of-the-art equipment and innovative processes that enhance production efficiency and product quality. Whether through the utilization of automated welding processes or the implementation of sophisticated quality control systems, manufacturers have succeeded in producing rods that adhere to international standards.

This technological edge enables Chinese manufacturers to produce a range of welding rods that cater to various applications. From automotive and aerospace industries to construction and shipbuilding, stainless steel rods from China are designed to withstand corrosive environments, making them highly desirable in sectors where durability is paramount.

Cost-Effective Production

China's cost-effective production capabilities also play a significant role in its dominance in the stainless steel welding rod market. The combination of affordable raw materials, competitive labor costs, and government incentives has allowed manufacturers to maintain lower prices without sacrificing quality. This cost advantage has enabled Chinese stainless steel welding rods to penetrate global markets, often outpricing domestic manufacturers in countries with higher production costs.

Moreover, mass production capabilities in China help in achieving economies of scale

. As manufacturers invest in large-scale operations, they can reduce per-unit costs significantly, making Chinese welding rods more accessible to international buyers.china stainless welding rod manufacturer

Strong Supply Chain and Logistics

The well-established supply chain and logistics infrastructure in China are instrumental in the success of its stainless steel welding rod manufacturers. With a vast network of suppliers providing everything from raw materials to packaging materials, manufacturers can streamline their production processes and reduce lead times. This efficiency allows companies to fulfill orders promptly and maintain a steady supply, which is crucial in industries that operate on tight schedules.

Additionally, China’s strategic geographical location and extensive shipping capabilities facilitate export to various regions, including North America, Europe, and Asia-Pacific. This global reach means that manufacturers can quickly respond to market demands and fluctuations, ensuring that they remain competitive.

Skilled Workforce

China’s substantial investment in education and vocational training has cultivated a skilled workforce proficient in manufacturing techniques. Engineers, technicians, and production workers in China are not only knowledgeable about cutting-edge technologies but also excel in quality control and sustainable practices. This combination of expertise contributes to the consistent production of high-quality stainless steel welding rods.

Furthermore, the commitment to research and development (R&D) within the manufacturing sector has led to innovations in welding rod formulations and applications, allowing for the continued improvement of product offerings.

Conclusion

As we look to the future, it is clear that China’s position as a leading manufacturer of stainless steel welding rods is firmly established. Through technological advancements, cost-effective production methods, a robust supply chain, and a skilled workforce, the country has positioned itself to meet the rising global demand for welding materials. As industries continue to evolve and seek high-performance, durable products, Chinese manufacturers are likely to remain at the forefront of this crucial sector, influencing global welding standards and practices for years to come.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025