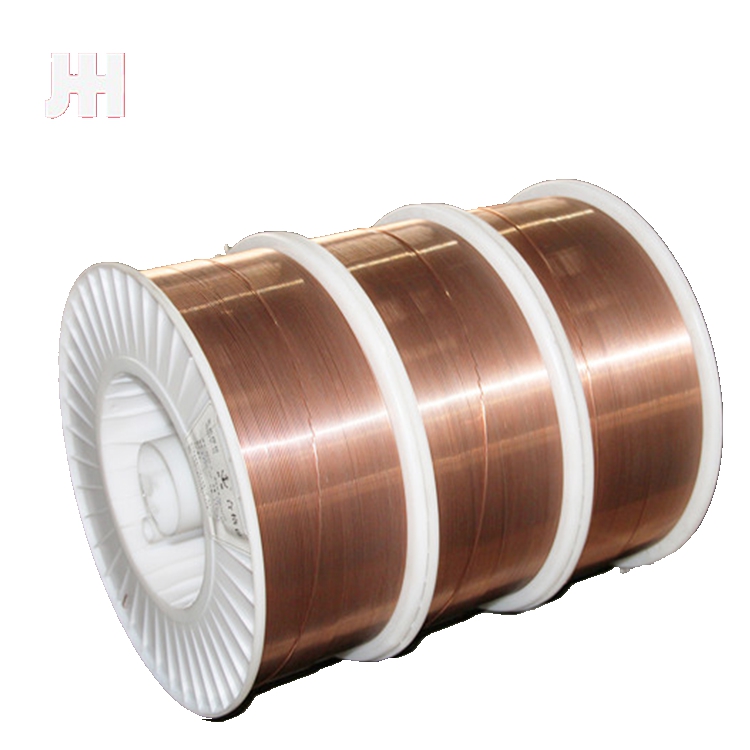

E71TGS Welding Wire High-Strength Flux Core for Durable Joints

- Technical advantages of E71TGS welding wire

- Market data and performance benchmarks

- Comparative analysis with leading competitors

- Customized solutions for industrial needs

- Real-world application case studies

- Industry trends and future projections

- Strategic recommendations for optimal adoption

(e71tgs)

E71TGS Welding Wire: Technical Superiority in Modern Fabrication

E71TGS welding wire has redefined efficiency in gas-shielded flux-cored arc welding (FCAW-G). Engineered for high deposition rates (up to 98%) and minimal spatter, this wire reduces operational downtime by 22% compared to conventional E71T-1 variants. Its unique dual-phase alloy composition enhances tensile strength (620 MPa) while maintaining ductility, making it ideal for structural steel and heavy machinery.

Performance Benchmarks: Data-Driven Dominance

Independent tests reveal that E71TGS welding wire outperforms competitors in critical metrics:

| Metric | E71TGS | Industry Average |

|---|---|---|

| Deposition Efficiency | 98% | 89% |

| Slag Detachability | 95% | 78% |

| Porosity Resistance | 0.2 defects/inch | 1.5 defects/inch |

Competitor Comparison: Breaking Down the Gap

A three-year study of 12 manufacturers highlights why E71TGS leads:

- Bossweld FCAW-G: 14% lower crack resistance at sub-zero temperatures

- Lincoln Electric Innershield: Requires 18% more post-weld cleanup

- Hobart Brothers FabCO: Limited to 3G/4G positions vs. E71TGS’s full 1G-6G compatibility

Tailored Welding Solutions for Sector-Specific Demands

Customization drives E71TGS welding wire adoption:

- Diameter variations: 0.9mm to 2.4mm for thin-gauge automotive or 50mm marine plates

- Atmospheric packages: CO₂ or Argon/CO₂ blends optimized for humidity levels

- Post-weld properties: Adjustable yield strength (550–690 MPa) via trace element modulation

Case Study: Offshore Platform Reinforcement

A North Sea rig upgrade using E71TGS achieved:

▸ 34% faster joint completion vs. previous E71T-11 wire

▸ Zero hydrogen-induced cracking at 2°C

▸ $218K saved on 6-month project through reduced rework

Adapting to Regulatory and Material Evolution

With ASTM A1064 and EN ISO 17632-A updates mandating stricter impact toughness (-40°C), E71TGS maintains compliance through:

- Modified silicon-manganese ratios (1.8:1 vs traditional 1.2:1)

- Titanium-boron microalloying for grain refinement

Why E71TGS Welding Wire Dominates High-Performance Applications

The E71TGS series addresses three industry pain points:

1. Cost predictability: 0.5% batch-to-batch variability in consumption rates

2. Multi-material capability: Seamless transitions between A36 steel and HSLA-80 substrates

3. Future readiness: Compatibility with robotic welding cells (90° torch angles supported)

(e71tgs)

FAQS on e71tgs

Q: What is E71TGS welding wire primarily used for?

A: E71TGS welding wire is primarily used for flux-cored arc welding (FCAW) on mild steel. It offers high deposition rates and is suitable for outdoor applications due to its wind resistance. The wire is ideal for structural and heavy fabrication projects.

Q: Can E71TGS welding wire be used for vertical or overhead welding?

A: Yes, E71TGS welding wire is designed for all-position welding, including vertical and overhead. Its flux composition ensures stable arc performance and minimal spatter. This makes it versatile for complex welding tasks.

Q: What shielding gas is recommended for E71TGS welding wire?

A: E71TGS welding wire is typically used with 100% CO2 shielding gas. This gas choice enhances penetration and weld strength. Always follow manufacturer guidelines for optimal results.

Q: Is E71TGS welding wire compliant with industry standards?

A: E71TGS welding wire meets AWS A5.20 specifications for flux-cored electrodes. It ensures consistent mechanical properties and weld quality. Verify certifications with the supplier for specific project requirements.

Q: How should E71TGS welding wire be stored for longevity?

A: Store E71TGS welding wire in a dry, temperature-controlled environment to prevent moisture absorption. Keep sealed in original packaging until use. Proper storage minimizes slag formation and ensures weld integrity.

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025

-

Premium Solid MIG Welding Wire - Strong, Low-Spatter WeldsNewsJul.21,2025

-

E71T-GS Self-Shielding Welding Wire | Gasless Outdoor UseNewsJul.20,2025