electrodo 1/16 6013 supplier

Understanding the Importance of Electrodo 1/16 6013 in Welding Applications

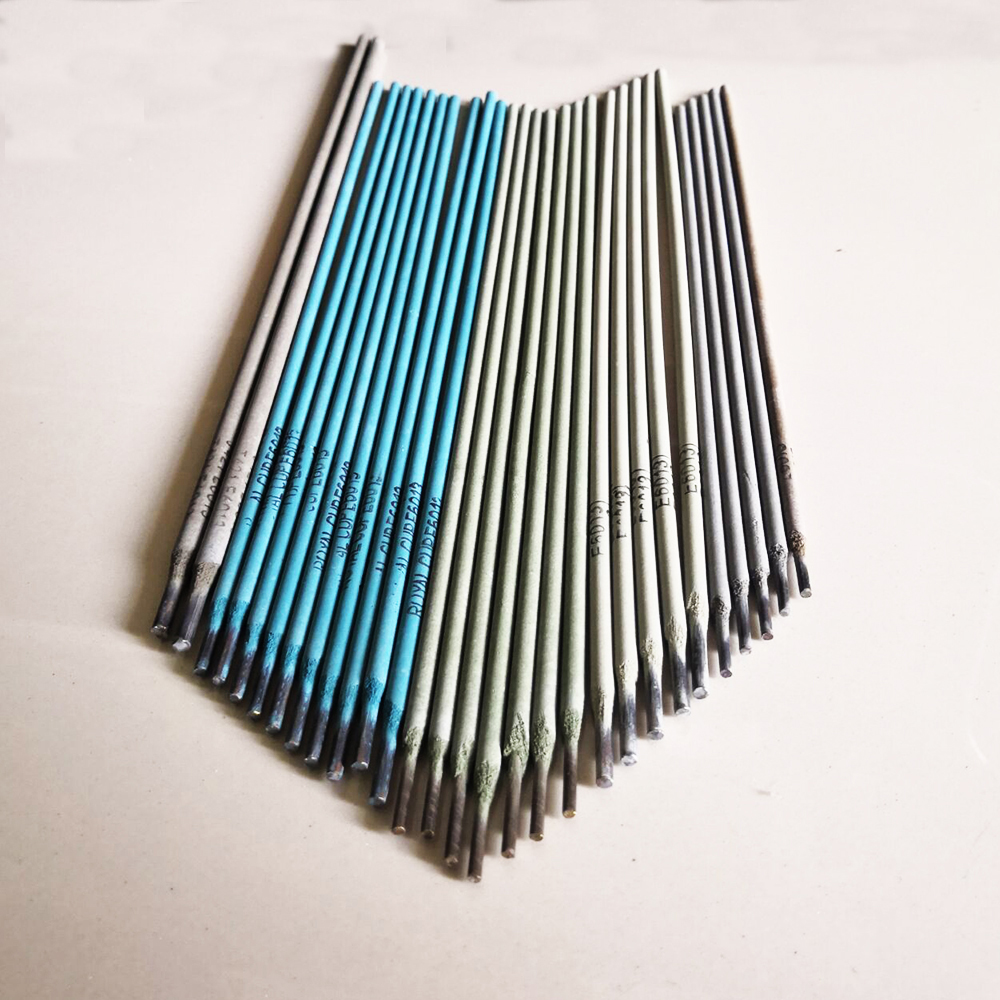

Welding is an essential process in various industries, from construction to manufacturing, and the selection of the right electrode can significantly impact the quality and efficiency of the welding process. Among the many options available, the Electrodo 1/16 6013 has garnered attention for its versatility and effectiveness. This article delves into the features of this electrode, its applications, and why selecting a reliable supplier is crucial for successful welding projects.

Characteristics of Electrodo 1/16 6013

Electrodo 1/16 6013 belongs to a series of mild steel electrodes known for their ease of use and high versatility. The “6013” designation indicates that these electrodes are suitable for welding mild steels with a coating designed to improve usability and arc stability. The diameter of 1/16 inches makes it ideal for applications requiring precision and finesse. Its usability in all positions of welding, including flat, horizontal, vertical, and overhead, makes it a go-to choice for many welders.

One of the most significant advantages of the Electrodo 1/16 6013 is its weld quality. It produces smooth and aesthetically pleasing beads, making it particularly suitable for projects where the appearance of the weld is important. This characteristic is especially valued in industries where visual appeal matters, such as art and decorative metalwork.

Applications

The Electrodo 1/16 6013 is widely used in various applications. Its versatility allows it to be employed in light to medium structural fabrication, repair jobs, and even in the automotive industry. It can be used on a wide range of metal thicknesses, making it suitable for both thin and thicker materials. Moreover, its ability to perform well under various conditions, including damp or dirty surfaces, adds to its appeal, allowing for more agility in diverse working environments.

In addition to mild steel, the Electrodo 1/16 6013 can also be utilized for welding low-alloy steels. This flexibility encourages manufacturers and welders to keep it as a staple in their welding kits. The electrode’s capacity to produce low spatter levels further reduces the need for excessive cleanup after welding, thereby enhancing operational efficiency.

electrodo 1/16 6013 supplier

Selecting a Reliable Supplier

When it comes to welding, having access to high-quality materials is essential. This is where the choice of a reliable supplier for Electrodo 1/16 6013 becomes crucial. A reputable supplier will guarantee that the electrodes meet industry standards, ensuring safe and effective welding processes.

Choosing the right supplier involves evaluating several factors. First and foremost, consider the supplier's reputation. Reviews and testimonials from previous customers can provide insights into the quality of the products offered. A supplier with a solid track record in the welding industry is more likely to provide electrodes that meet the necessary specifications.

Additionally, consider the range of products offered by the supplier. A well-established supplier should provide a variety of welding electrodes and equipment to cater to different needs. Furthermore, assess their customer service. Efficient communication, prompt delivery, and support services can significantly enhance the overall purchasing experience.

Finally, price is always a consideration, but it should not be the sole factor in your decision-making process. While competitive pricing is essential, it should not come at the expense of quality. The long-term benefits of investing in high-quality electrodes from a reputable supplier often outweigh the initial costs.

Conclusion

In conclusion, the Electrodo 1/16 6013 is a valuable asset in the world of welding, offering versatility, ease of use, and quality. Whether in structural fabrication or artistic applications, its impact is significant. However, to maximize its potential, it is essential to source these electrodes from trusted suppliers who prioritize quality and customer satisfaction. By doing so, welders can ensure successful outcomes in their projects, enhancing both productivity and weld integrity.

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025