spot welding wire factory

The Evolution and Importance of Spot Welding Wire Factories

Spot welding has become an indispensable technique in various manufacturing processes, particularly in the automotive, electronics, and construction industries. As the demand for high-quality welded joints increases, so too does the necessity for specialized materials like spot welding wire. This article explores the significance of spot welding wire factories, their technological advancements, and their vital role in modern manufacturing.

Understanding Spot Welding

Spot welding is a resistance welding process that joins two or more metal sheets together by applying heat generated from electrical resistance. The process involves the use of spot welding electrodes, which deliver electrical current to the workpieces. This creates heat at the interface of the metals, resulting in a weld nugget. The quality of this weld is predominantly influenced by the materials used, particularly the welding wire.

The Role of Spot Welding Wire Factories

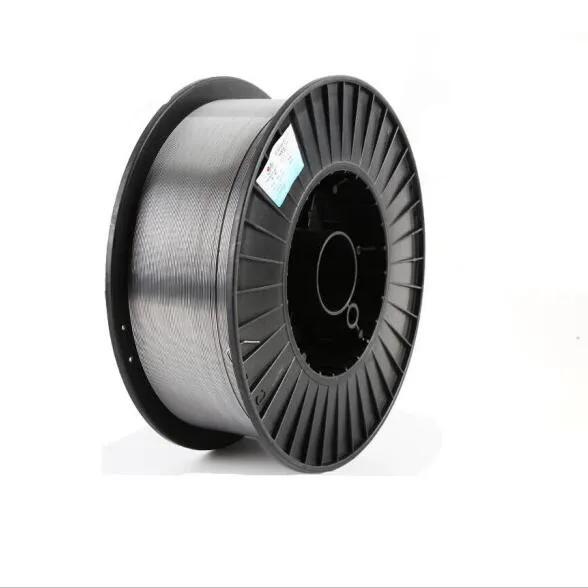

Spot welding wire is typically made from high-quality materials that can withstand significant mechanical stress and thermal cycling. Spot welding wire factories play a crucial role in producing these specialized wires. They ensure that the wire meets stringent standards in terms of conductivity, strength, and durability. These factories employ state-of-the-art manufacturing processes that utilize advanced materials and technology to produce consistent and reliable spot welding wire.

Technological Advancements in Manufacturing

In recent years, spot welding wire factories have integrated advanced technologies into their production processes. Automation and robotics have enhanced efficiency, allowing for higher production rates and reduced human error. The incorporation of real-time monitoring systems has also improved quality control. These systems can detect anomalies during the manufacturing process, ensuring that any defective product is identified and rectified immediately.

Furthermore, the development of new alloys and materials has propelled the evolution of spot welding wire. Factories now produce wires that offer better performance in terms of tensile strength and electrical conductivity. These innovations are vital in meeting the evolving demands of industries, particularly in applications requiring lightweight yet strong materials, such as the automotive industry.

spot welding wire factory

Environmental Considerations

The environmental impact of manufacturing processes is a growing concern across all industries. Spot welding wire factories are increasingly adopting sustainable practices to minimize their ecological footprint. This includes recycling materials, reducing waste, and implementing energy-efficient technologies. By optimizing production processes and sourcing raw materials responsibly, factories contribute to a greener manufacturing ecosystem.

The Future of Spot Welding Wire Production

As industries continue to evolve, so will the demands for spot welding wire. The growing focus on electric vehicles (EVs) and renewable energy technologies presents new challenges and opportunities for spot welding wire factories. These sectors require wires that can effectively handle higher currents and provide superior structural integrity in demanding environments.

Moreover, with the proliferation of Industry 4.0 concepts—including the Internet of Things (IoT) and machine learning—spot welding wire factories are likely to adopt increasingly intelligent systems. These systems can optimize production schedules, predict maintenance needs, and even tailor products to specific customer requirements based on real-time data analysis.

Conclusion

Spot welding wire factories play a pivotal role in the manufacturing landscape. Their ability to produce high-quality, reliable welding wires is essential for various industries, from automotive to aerospace. As technological advancements continue to shape these factories, the importance of innovation, sustainability, and quality control in manufacturing will remain paramount.

Looking ahead, the integration of smarter production techniques and sustainable practices will not only enhance the efficiency of spot welding wire factories but also continue to meet the ever-evolving demands of modern manufacturing. This evolution not only reflects the industrious nature of the sector but also ensures that it remains at the forefront of technological advancement—enabling manufacturers to produce high-quality products that meet the global market's needs.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025