Suppliers of 2.5mm E7018 Welding Electrodes for Reliable Welding Solutions

The Importance of E7018 Welding Electrode Suppliers and Specifications

Welding is an essential process in various industries, including construction, manufacturing, and repair. One of the most commonly used welding electrodes is the E7018, especially known for its versatility and strong welds in structural steel. This article will delve into the characteristics of the E7018 welding electrode, particularly the 2.5mm variant, and explore its suppliers and applications.

What is E7018?

The E7018 welding electrode is classified under the American Welding Society (AWS) specification for low-hydrogen electrodes. The E stands for electrode, 70 indicates the minimum tensile strength of 70,000 psi, and 18 denotes the type of coating and the welding position flat, horizontal, vertical, and overhead. One of the standout features of E7018 is its ability to produce strong, ductile welds with excellent impact resistance.

Characteristics of E7018 2.5mm Electrode

The 2.5mm diameter E7018 electrode is popular in various welding applications, particularly in the construction and fabrication of structures that require reliability and strength. Some of the key characteristics include

1. Low Hydrogen Content The coating contains low levels of hydrogen, which minimizes the risk of hydrogen-induced cracking. This is particularly important in high-strength steels.

2. High Ductility E7018 electrodes produce welds that can withstand significant deformation without fracturing. This property is essential for structures subject to dynamic loading.

3. Versatile Usage The E7018 electrode can be used for both DC and AC welding processes, making it suitable for various welding machines. Its adaptability increases its utility in different scenarios.

4. Excellent Arc Stability The arc generated by E7018 is smooth and stable, allowing for better control and precision during the welding process.

5. Good Surface Finish Welds created with E7018 exhibit a smooth finish and minimal spatter, making post-weld cleaning easier and improving aesthetic quality.

Applications of E7018 2

.5mm Electrodewelding electrode e7018 2.5mm suppliers

The E7018 welding electrode is utilized in various industries, including but not limited to

- Structural Steel Construction Used in building bridges, high-rise buildings, and frameworks that require strong welds. - Marine Fabrication Employed in constructing ships and underwater pipelines where reliability is critical. - Heavy Equipment Manufacturing Used in fabricating parts and assemblies that undergo heavy stress and are subject to impact. - Repair Work Ideal for repairing cracks and faults in existing structures, ensuring structural integrity.

Finding E7018 2.5mm Electrode Suppliers

Finding a reliable supplier for E7018 electrodes is crucial for anyone in the welding industry. Here are some tips

1. Research Online Start by searching for suppliers online. Many manufacturers and distributors have dedicated websites where you can check their product offerings and specifications.

2. Read Reviews Customer reviews and testimonials can provide insights into the quality of the electrodes and the reliability of the supplier.

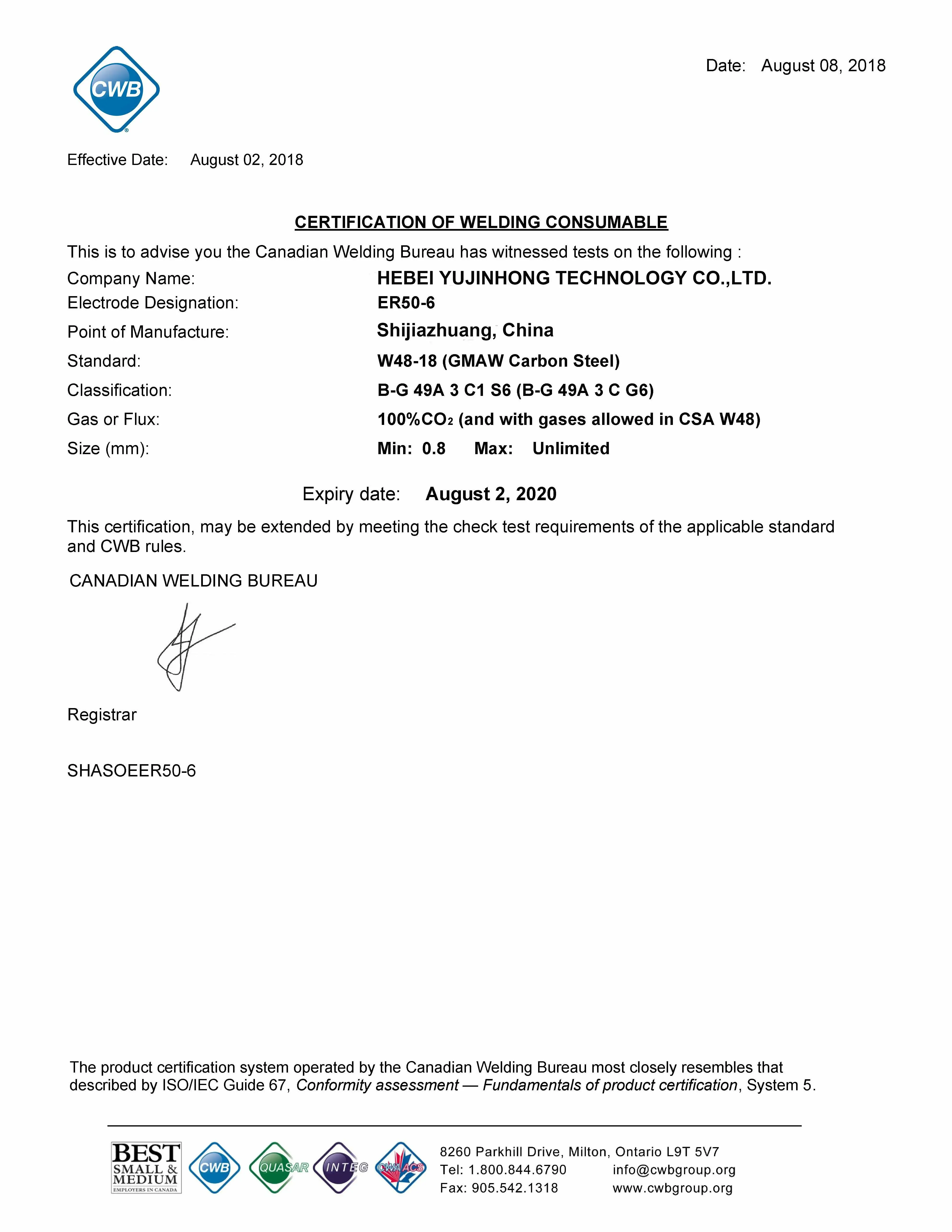

3. Check Certifications Ensure that the supplier complies with industry standards and certifications, which guarantees the quality of the electrodes.

4. Request Samples If possible, request samples of the E7018 2.5mm electrodes to assess their quality before making a bulk order.

5. Comparative Pricing Compare prices among different suppliers to get the best deal without compromising on quality.

Conclusion

The E7018 2.5mm welding electrode is a vital component in many welding applications, known for its strength, versatility, and reliability. Understanding its characteristics and applications can help professionals make informed decisions when it comes to sourcing welding supplies. Whether you are involved in construction, manufacturing, or repair work, locating a dependable E7018 supplier is key to achieving high-quality welds that stand the test of time.

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025