Ақп . 13, 2025 18:24

Back to list

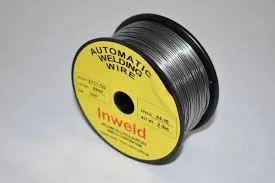

E6013 Welding Electrode Rods for carbon steel

Navigating the world of wholesale welding rods requires a blend of expertise and strategic choice. Welding rods, an essential component for binders in fusing metals, vary significantly depending on the material and type of welding. Thirty years of interactions with welding professionals and industrial clients have offered me vast insights into sourcing the best wholesale welding rods.

The authoritative voice in the welding industry stems from consistent updates and research in metallurgy and material science. Attending annual conferences and exhibitions globally sheds light on cutting-edge manufacturing techniques and innovative solutions, keeping industry professionals ahead in a rapidly evolving market. For instance, advancements in cryogenic processing of rods have shown remarkable improvements in their tensile strength and longevity, a fact validated by studies from leading metallurgy institutions. By sharing these innovations through seminars and online platforms, sellers and buyers stay informed, positioning themselves as trusted leaders in the welding domain. Trustworthiness, meanwhile, is cultivated through transparent business practices and customer empowerment. An efficient supplier wins trust by providing comprehensive guidance on product selection, application safety, and cost-benefit analysis, rather than merely focusing on bulk sales. Numerous clients have shared testimonials where clear communication and after-sales support significantly influenced their purchasing decisions. Establishing dedicated technical support and consultation services ensures customers feel valued, turning one-time transactions into long-term partnerships. The journey of acquiring wholesale welding rods is not solely a transactional experience, but one of cultivating relationships grounded in knowledge, reliability, and foresight. Tailoring solutions that meet precise project demands solidifies a buyer's standing and aligns with E-A-T (Experience, Expertise, Authoritativeness, and Trustworthiness) principles. So, whether an enterprise is launching new infrastructures or maintaining existing ones, prioritizing these aspects transforms a process fraught with potential pitfalls into a strategic advantage, driving both quality and success.

The authoritative voice in the welding industry stems from consistent updates and research in metallurgy and material science. Attending annual conferences and exhibitions globally sheds light on cutting-edge manufacturing techniques and innovative solutions, keeping industry professionals ahead in a rapidly evolving market. For instance, advancements in cryogenic processing of rods have shown remarkable improvements in their tensile strength and longevity, a fact validated by studies from leading metallurgy institutions. By sharing these innovations through seminars and online platforms, sellers and buyers stay informed, positioning themselves as trusted leaders in the welding domain. Trustworthiness, meanwhile, is cultivated through transparent business practices and customer empowerment. An efficient supplier wins trust by providing comprehensive guidance on product selection, application safety, and cost-benefit analysis, rather than merely focusing on bulk sales. Numerous clients have shared testimonials where clear communication and after-sales support significantly influenced their purchasing decisions. Establishing dedicated technical support and consultation services ensures customers feel valued, turning one-time transactions into long-term partnerships. The journey of acquiring wholesale welding rods is not solely a transactional experience, but one of cultivating relationships grounded in knowledge, reliability, and foresight. Tailoring solutions that meet precise project demands solidifies a buyer's standing and aligns with E-A-T (Experience, Expertise, Authoritativeness, and Trustworthiness) principles. So, whether an enterprise is launching new infrastructures or maintaining existing ones, prioritizing these aspects transforms a process fraught with potential pitfalls into a strategic advantage, driving both quality and success.

Previous:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025