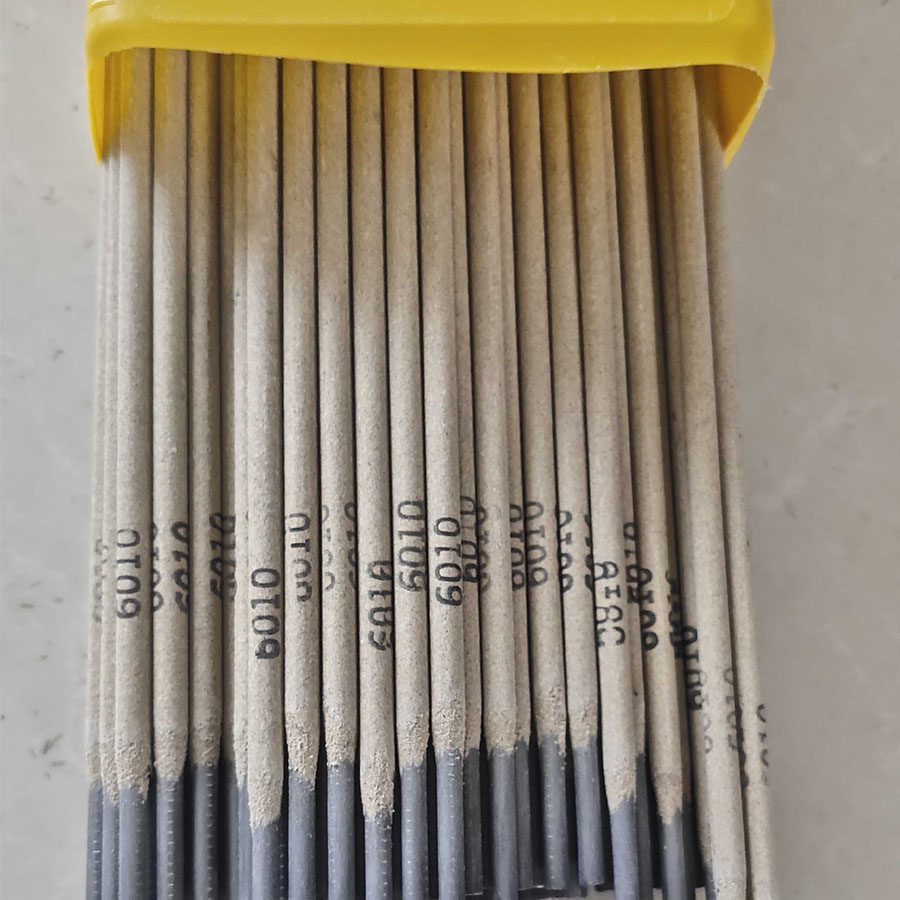

6013 welding electrodes supplier

Understanding 6013 Welding Electrodes A Comprehensive Guide for Suppliers

Welding is an essential process in various industries, serving as a critical method for joining materials and creating lasting structures. Among the various welding electrodes available in the market, the 6013 welding electrode stands out as a popular choice among professionals and suppliers. This article delves into the characteristics, applications, and the role of suppliers in distributing 6013 welding electrodes effectively.

What are 6013 Welding Electrodes?

6013 welding electrodes are a type of mild steel electrode used in arc welding processes. The 60 in the designation indicates a minimum tensile strength of 60,000 psi, while the 1 signifies that it is suitable for all-position welding, and the 3 denotes the type of coating. The coating on a 6013 electrode is primarily made of cellulose and other materials that contribute to its ease of use, smooth arc stability, and excellent bead appearance.

These electrodes are designed for use with alternating current (AC) or direct current (DC) power sources, making them versatile for various welding applications. The low hydrogen content of the coating helps reduce the risk of hydrogen-induced cracking, making 6013 electrodes a reliable choice for many welding projects.

Key Features of 6013 Electrodes

1. Versatility The 6013 electrodes can be used on a variety of materials, including mild steel, making them suitable for numerous welding tasks. They are suitable for sheet metal and structural work.

2. Ease of Use One of the significant advantages of 6013 welding electrodes is their forgiving nature. They are known for producing a stable arc, which makes them ideal for both novice welders and professionals. Their ability to perform well in all positions also adds to their popularity.

3. Good Appearance The welds produced using 6013 electrodes are known for their smooth finish and minimal spatter, which is a crucial aspect for aesthetic applications and industries requiring high-quality finishes.

4. Strong Mechanical Properties Welds made with 6013 electrodes exhibit strong mechanical properties, making them suitable for structural applications where strength and integrity are paramount.

Applications of 6013 Welding Electrodes

6013 welding electrodes supplier

6013 welding electrodes are widely used across various sectors. Common applications include

- Automotive Repair Ideal for various automotive components that require strong but lightweight joins. - Construction Frequently utilized in building frameworks and miscellaneous structures where mild steel is needed. - Manufacturing Common in both machinery and general fabrication work. - Home Projects Favored for DIY welders due to their ease of use and availability.

Role of Suppliers in the Market

As the demand for 6013 welding electrodes increases, suppliers play a vital role in ensuring that professionals and industries have access to these essential materials. Here are a few responsibilities and opportunities for welding electrode suppliers

1. Quality Assurance Suppliers must ensure that the 6013 electrodes they provide meet industry standards and regulations, offering high-quality products that welders can rely upon.

2. Diverse Inventory Maintaining a diverse inventory of different sizes and coatings of 6013 electrodes can cater to varying customer needs, enhancing the supplier’s market reach.

3. Customer Support Suppliers should provide knowledgeable support and guidance to customers regarding the selection and usage of 6013 electrodes, helping welders make informed decisions.

4. Training and Resources Offering training sessions, workshops, and resources can empower customers to use welding electrodes more effectively and safely, promoting long-term customer loyalty.

5. Sustainability With an increasing emphasis on environmentally friendly practices, suppliers could explore sustainable options and educate customers on responsible usage and disposal of welding materials.

Conclusion

The 6013 welding electrode is a crucial component in the welding industry, offering versatility, ease of use, and strong mechanical properties. As the demand for these electrodes continues to grow, suppliers play a pivotal role in ensuring their availability, quality, and compliance. By understanding the characteristics and applications of 6013 welding electrodes, suppliers can better serve the needs of their customers, contributing to the success of welding projects across various sectors.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025