china soldador electrodos factory

The Emergence of China's Electrode Welding Rod Manufacturing Industry

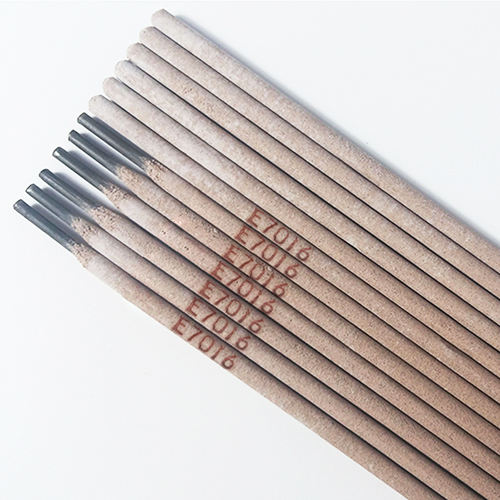

In recent years, China has become a significant player in the global market for welding electrodes and rods, reflecting the country's rapid industrialization and technological advancements. The term soldador electrodos, which translates to welding electrodes in English, encapsulates a vital component of various manufacturing and construction processes, making it crucial to understand the dynamics of this sector.

Welding electrodes and rods are essential for various welding methods, offering the necessary material to create strong joints between metal pieces. These components are used in diverse industries, including construction, automotive, shipbuilding, and heavy machinery manufacturing. The fact that China has emerged as a leading manufacturer can be attributed to several factors, including cost-effectiveness, technological improvements, and a robust supply chain.

The Emergence of China's Electrode Welding Rod Manufacturing Industry

Furthermore, Chinese manufacturers have increasingly adopted advanced technologies and modern production techniques. Investing in research and development has allowed these companies to produce electrodes that not only meet international standards but often exceed them. Innovations in materials and manufacturing processes, such as improved shielding gases and alloy formulations, have enhanced the performance of welding electrodes. This commitment to quality is essential as industries worldwide demand more efficient and durable welding solutions.

china soldador electrodos factory

Moreover, China's well-established infrastructure is a crucial asset. With a dense network of transportation systems—including railways, highways, and ports—efficiency in distributing welding products is significantly improved. This logistical advantage helps manufacturers respond quickly to market demands, reducing lead times and costs for customers.

The global demand for welding rods and electrodes continues to grow, driven by emerging markets and the ongoing need for infrastructure development. As countries invest in construction and manufacturing, China's role as a supplier is vital. The various international trade agreements and incentives for partnerships further encourage the export of these materials. Chinese companies actively seek collaborations and joint ventures with firms in different regions to expand their market reach and share best practices in production and technology.

However, the growth of the welding electrode industry in China is not without challenges. The increasing competition, both from domestic producers and burgeoning manufacturing hubs in other countries, poses risks to market share and profitability. Additionally, environmental regulations are becoming stricter, requiring manufacturers to adopt greener practices. This shift may involve additional costs in transitioning to more environmentally friendly materials and processes, but it also presents an opportunity for innovation and differentiation in the market.

Another critical aspect is the focus on quality and adherence to international standards. As China's products compete on the world stage, manufacturers must ensure that their electrodes meet diverse compliance requirements, including those from the American Welding Society (AWS) and European standards. Achieving certifications can be time-consuming and expensive but is essential for gaining trust and establishing a solid reputation among global clients.

In conclusion, China's welding electrode manufacturing industry is a microcosm of the broader economic transformation occurring within the country. Its blend of cost-effective production, technological innovation, and efficient supply chains positions it as a formidable player in the global market. While challenges exist, the continued growth and evolution of this sector will likely play a significant role in addressing the world's increasing demand for reliable welding solutions. As China continues to refine its practices, the future of electrode manufacturing in the country appears promising, with the potential for sustainable development and enhanced international collaboration.

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025

-

Premium Solid MIG Welding Wire - Strong, Low-Spatter WeldsNewsJul.21,2025

-

E71T-GS Self-Shielding Welding Wire | Gasless Outdoor UseNewsJul.20,2025

-

E312 Welding Electrode - High Corrosion Resistance & All-Purpose UseNewsJul.20,2025