china stainless mig wire 1.2mm supplier

Understanding the Role of China Stainless MIG Wire 1.2mm Suppliers

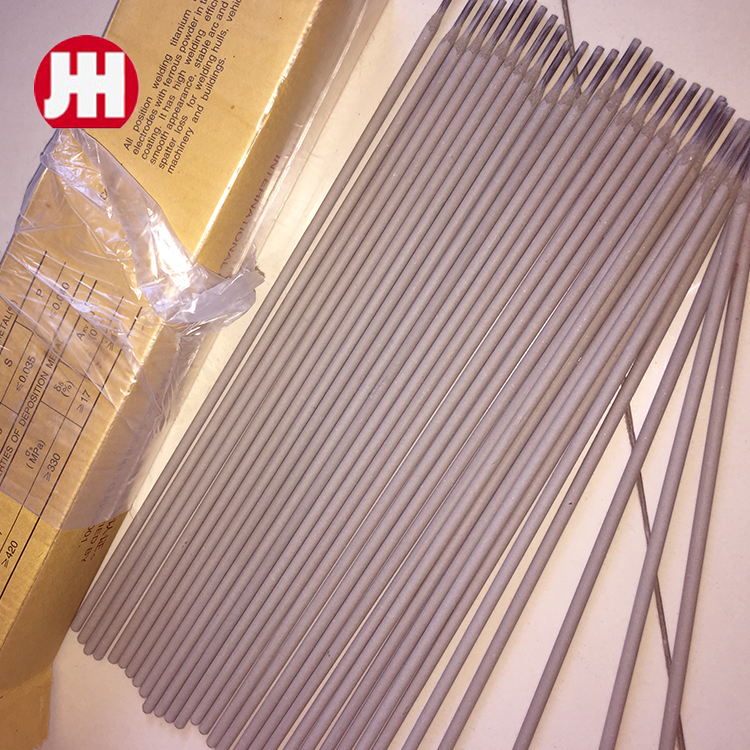

In recent years, the global demand for high-quality welding materials has surged, particularly in the construction, automotive, and manufacturing industries. One essential component in this domain is the stainless steel MIG (Metal Inert Gas) welding wire. Notably, suppliers from China have become key players in the market, offering products that cater to a variety of industrial needs. Among them, the 1.2mm stainless MIG wire stands out as a popular choice for many welding applications.

The Significance of Stainless Steel in Welding

Stainless steel is renowned for its corrosion resistance, strength, and aesthetic appeal, making it an ideal material for various applications. In welding, stainless steel wires are used to join components that require durability and resistance to harsh environments. The versatility of stainless MIG wire allows it to be used in multiple sectors, from maritime to food processing facilities.

The 1.2mm diameter stainless MIG wire is particularly valued for its balance between ease of handling and the ability to produce strong welds. It is suitable for both novice and experienced welders, making it a preferred choice in training facilities and various industrial setups.

China's Role in the Global Market

China has emerged as a leading supplier of stainless MIG wire globally, with numerous manufacturers specializing in different grades and types of wires. The country boasts advanced production technologies and extensive expertise in metallurgy, enabling it to produce wires that meet international standards.

Chinese suppliers often offer a wide range of products, including ER308, ER316, and other alloys, tailored to meet specific welding requirements. The ability to customize products according to the needs of different markets is a significant advantage for Chinese manufacturers. Furthermore, the competitive pricing of these products makes them accessible to businesses of all sizes, driving further demand.

Quality Assurance and Standards

china stainless mig wire 1.2mm supplier

When sourcing stainless MIG wire, particularly from Chinese suppliers, quality assurance is a critical consideration. Many reputable manufacturers adhere to international quality standards such as ISO 9001, which ensures that their products meet rigorous testing and performance criteria. It is crucial for buyers to look for certifications and quality guarantees when selecting a supplier.

Additionally, many manufacturers in China invest in research and development to improve the properties of their welding wires. This includes enhancing the wire’s resistance to temperature fluctuations and improving the fluidity of the molten weld pool to achieve better penetration and bead profiles.

The Benefits of Sourcing from Chinese Suppliers

1. Cost-Effectiveness One of the most compelling reasons to source stainless MIG wire from China is the cost. Lower production costs, combined with favorable trade agreements, often result in competitive pricing that benefits end-users.

2. Diverse Product Range Chinese suppliers typically offer an extensive selection of stainless MIG wires in various diameters and alloy compositions. This allows customers to find the exact product suitable for their specific applications.

3. Efficient Supply Chains With significant advancements in logistics, many Chinese suppliers can ensure timely deliveries and maintain efficient inventory systems, which is crucial for businesses that rely on just-in-time manufacturing processes.

4. Strong Technical Support Many Chinese manufacturers provide comprehensive pre-and post-sale technical support, helping clients troubleshoot issues and maximize the performance of their products.

Conclusion

The demand for stainless MIG wire, particularly the 1.2mm variant, continues to grow as industries seek reliable and durable welding solutions. Chinese suppliers have positioned themselves as vital contributors to this market, offering a combination of quality, variety, and affordability. However, when selecting a supplier, it is crucial to consider their certification, production capabilities, and customer service. By making informed choices, businesses can leverage the advantages of sourcing from China while ensuring the quality and reliability of their welding operations.

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025

-

E7016 Welding Rods for High Strength & Low Hydrogen WeldingNewsJul.29,2025

-

High Quality Carbon Rods for Welding – Durable & Precise ResultsNewsJul.29,2025

-

High-Performance Cellulose Electrode E6010 for Steel WeldingNewsJul.28,2025

-

High Quality E71T-11 Welding Wire from China – Flux Cored, Easy to UseNewsJul.28,2025

-

High-Quality SG2 Welding Wire for Superior PerformanceNewsJul.27,2025