china stainless steel flux core wire supplier

The Rise of China as a Leading Supplier of Stainless Steel Flux Core Wire

In the ever-evolving landscape of global manufacturing, China has emerged as a significant player in the production and supply of stainless steel flux core wire. This specialized welding material has gained traction in various industries due to its efficiency and versatility. As the demand for high-quality welding products continues to rise, understanding the position of China as a supplier is crucial for manufacturers and welders alike.

Understanding Stainless Steel Flux Core Wire

Stainless steel flux core wire is a type of welding wire that is utilized in a process called flux-cored arc welding (FCAW). This process involves a tubular wire filled with flux that provides shielding gas during the welding process, making it possible to weld in various positions and conditions. The wire is particularly beneficial in environments where traditional MIG (Metal Inert Gas) welding is not feasible, such as outdoor applications or windy conditions. The corrosion-resistant properties of stainless steel make it ideal for sectors such as construction, automotive, and shipbuilding.

China’s Manufacturing Capability

China’s manufacturing capabilities are vast, thanks to its robust industrial infrastructure, advanced technologies, and skilled labor force. The country has invested heavily in welding technologies over the past two decades, leading to improved production methods and higher-quality products. Chinese manufacturers have adopted state-of-the-art machinery and techniques that ensure the consistency and reliability of their stainless steel flux core wires.

The production of stainless steel flux core wire involves precise formulation of the wire and flux materials. China’s manufacturers excel in using a variety of stainless steel grades, including 308, 309, and 316, which cater to different welding requirements and ensure optimal performance under various conditions.

Quality and Standards

Quality assurance is a critical aspect of the stainless steel flux core wire industry. Many Chinese suppliers adhere to international standards, such as ASTM and ISO, ensuring that their products meet the stringent demands of global markets. The implementation of quality control measures during the production process guarantees that every spool of wire meets the required specifications and performance criteria.

china stainless steel flux core wire supplier

Additionally, some manufacturers in China have obtained various certifications which bolster their reputation as trustworthy suppliers. These certifications instill confidence among international buyers, encouraging them to source their materials from China.

Competitive Pricing

One of the key advantages of sourcing stainless steel flux core wire from China is cost-effectiveness. Chinese manufacturers can offer competitive prices due to lower production costs, economies of scale, and the extensive supply chain networks established within the country. This enables businesses from around the world to access high-quality welding materials at a fraction of the cost compared to other markets.

This competitive pricing does not compromise quality; instead, it provides an opportunity for both small and large-scale industries to enhance their production processes without incurring exorbitant expenses.

Global Demand and Market Trends

The global demand for stainless steel flux core wire is rising, driven by various factors such as infrastructure development, increased manufacturing activities, and the need for durable and corrosion-resistant materials. As nations invest in green technologies and sustainable practices, the demand for stainless steel products, including flux core wire, is projected to grow.

China, as a leading supplier, is well-positioned to cater to this increasing demand. The country’s ability to scale production quickly and adapt to market changes enables it to respond effectively to the fluctuating needs of global industries.

Conclusion

As a dominant supplier of stainless steel flux core wire, China's impact on the welding industry cannot be understated. With its advanced manufacturing capabilities, commitment to quality, competitive pricing, and responsiveness to global demand, Chinese manufacturers are poised to lead the market for years to come. For businesses and welders seeking reliable welding materials, China presents an attractive source of high-quality stainless steel flux core wire that can meet their diverse needs. Engaging with Chinese suppliers can be a strategic move for those looking to enhance their operational efficiency and product quality in an increasingly competitive landscape.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

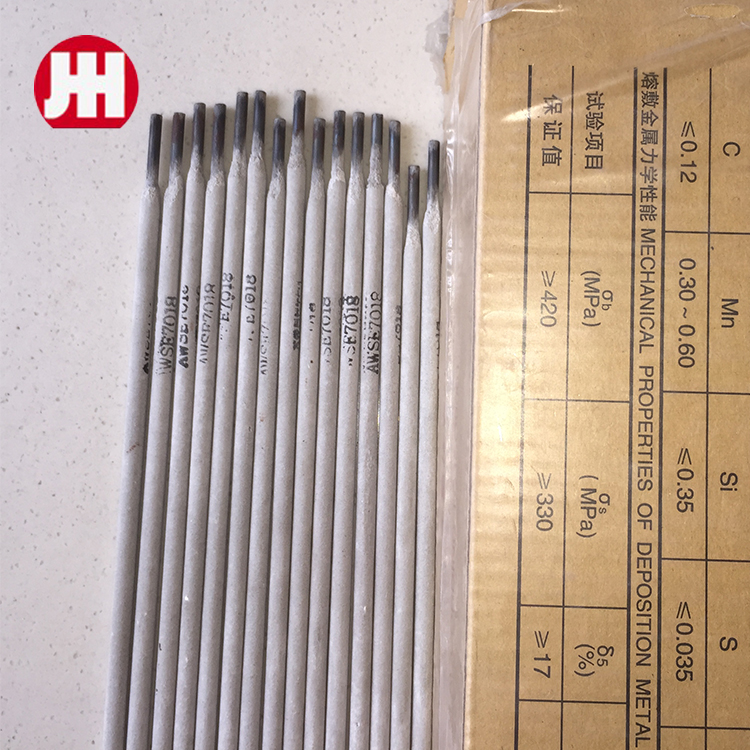

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025