Top Manufacturers of ER70S-6 MIG Welding Wire in China

The Global Landscape of China’s Welding Wire ER70S-6 MIG Manufacturers

In the world of welding, the quality of materials plays a pivotal role in determining the overall performance and durability of welded structures. Among the various types of welding wires, ER70S-6 is particularly noteworthy, especially in the context of MIG (Metal Inert Gas) welding. As industries continue to evolve, the demand for high-quality welding wires, including ER70S-6, has surged, with Chinese manufacturers leading the charge on a global scale.

Understanding ER70S-6 MIG Welding Wire

ER70S-6 is a popular type of solid wire used in MIG welding, primarily made of mild steel. It is known for its exceptional performance in welding clean, new metal as well as in welding applications involving thin-walled sections. The “ER” in ER70S-6 stands for Electrode Rod, with 70 indicating the minimum yield strength of 70,000 psi, S signifying it is a solid wire, and -6 pointing to specific mechanical properties, including increased manganese and silicon content. This composition makes the wire especially effective for the high-impact and high-heat environments typically encountered in structural welding applications.

The Rise of Chinese Manufacturers

The rise of China as a hub for manufacturing welding wires, particularly ER70S-6 MIG wire, can be attributed to several factors. First and foremost is the scale of production. Chinese manufacturers have established large-scale operations that allow them to produce high volumes of welding wire efficiently. This scale not only lowers production costs but also keeps prices competitive on the international stage.

Additionally, Chinese manufacturers have increasingly focused on adopting advanced manufacturing technologies. With substantial investments in research and development, many companies are now capable of producing high-quality welding wires that meet or exceed international standards. Certifications such as ISO9001, AWS, and EN norms have become common, ensuring that the products are reliable and safe for various welding applications.

Quality Control and Product Assurance

Quality control is crucial in the production of welding wires. Leading Chinese manufacturers implement stringent quality control processes throughout their manufacturing lines, from raw material sourcing to final product inspection. Rigorous testing procedures, including tensile and impact tests, ensure the consistency and reliability of the ER70S-6 MIG wire produced. The commitment to quality not only satisfies domestic demands but also bolsters confidence among international customers.

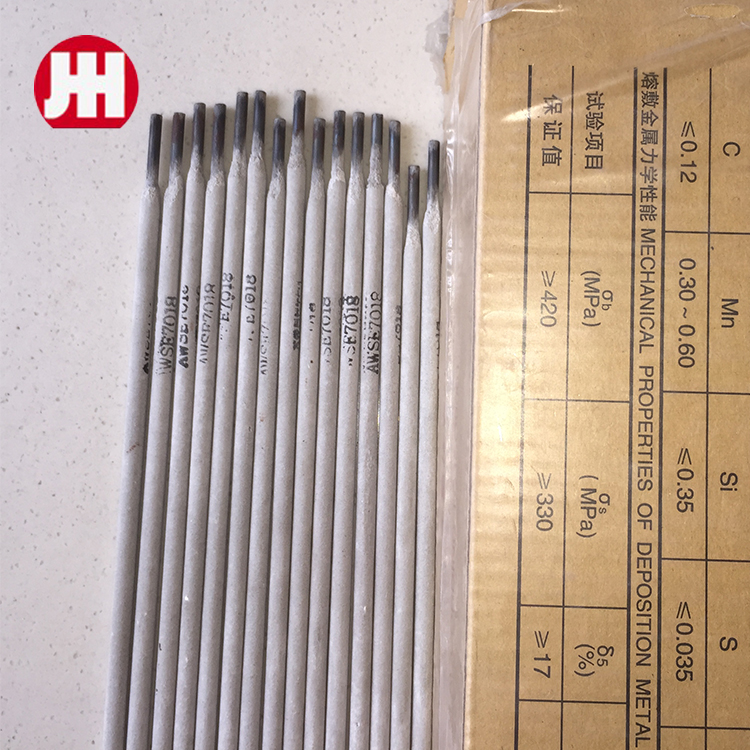

china welding wire er70s-6 mig manufacturer

Global Market Reach

China’s dominance in the ER70S-6 MIG wire market is not confined to its borders; it extends globally. Chinese manufacturers export significant quantities of welding wire to countries across North America, Europe, Asia, and beyond. The ability to deliver consistent quality combined with competitive pricing has made Chinese welding wire an appealing choice for many distributors and end-users.

Furthermore, with the rise of e-commerce platforms and global trade, Chinese manufacturers can efficiently reach customers worldwide. This accessibility has facilitated partnerships and collaborations between manufacturers and consumers, fostering an environment where feedback and innovation can thrive.

Future Trends

Looking ahead, the future of ER70S-6 MIG welding wire, particularly from China, appears promising. As industries continue to evolve towards automation and robotics in welding, manufacturers will need to adapt their products to meet new requirements. Innovations in welding wire formulations, enhanced performance characteristics, and eco-friendly manufacturing processes are already on the horizon.

Additionally, as global construction and manufacturing demand increases, the potential for growth in the welding wire sector remains high. Companies that can leverage advanced technologies, sustainability practices, and robust supply chains will likely emerge as leaders in the field.

Conclusion

The landscape of ER70S-6 MIG welding wire manufacturing is heavily influenced by Chinese manufacturers, who continue to play a critical role in ensuring that high-quality welding materials are available to meet an ever-growing global demand. With their commitment to quality, innovation, and efficiency, Chinese manufacturers have solidified their position in the international welding wire market, setting the stage for future advancements in welding technology and applications. As the industry evolves, staying abreast of these developments will be crucial for manufacturers, distributors, and users alike.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025