E7016 Welding Rod Manufacturer - High-Quality Welding Solutions

Understanding E7016 Welding Rods A Comprehensive Guide

When it comes to selecting the right welding rod for your project, the E7016 welding rod stands out as a popular choice among professionals and hobbyists alike. Known for its versatility and strong welding capabilities, the E7016 rod is an essential tool in various welding applications. This article aims to provide an informative overview of the E7016 welding rod, including its composition, applications, and key manufacturers.

What is an E7016 Welding Rod?

The designation E7016 provides essential information about the rod's properties. The E signifies that the rod is an electrode, while 70 indicates its minimum tensile strength of 70,000 psi. The 1 denotes that it is suitable for all positions, and the 6 indicates the type of coating — in this case, a low hydrogen potassium electrode. This specific composition makes E7016 rods particularly effective for welding in environments where moisture and contaminants are concerns.

Composition and Features

The E7016 welding rod is typically made with a mild steel core and coated with a low-hydrogen flux. This coating is crucial as it helps to stabilize the arc and reduce the risk of hydrogen embrittlement, which can be detrimental to the quality of the weld. The low hydrogen content ensures that the welds are strong and less prone to cracking, making them ideal for high-stress applications.

Moreover, E7016 rods are designed to provide excellent bead appearance and smooth arc stability. They can weld in any position, which adds to their versatility and makes them suitable for various projects, from pipeline construction to structural fabrication.

Applications of E7016 Welding Rods

E7016 welding rods are commonly used in a range of applications, particularly where high strength and durability are critical. Their ability to withstand harsh environments makes them ideal for structural steel fabrication, shipbuilding, and pressure vessel fabrication. These rods are particularly favored in industries that require welding on thicker materials, where both penetration and strength are crucial.

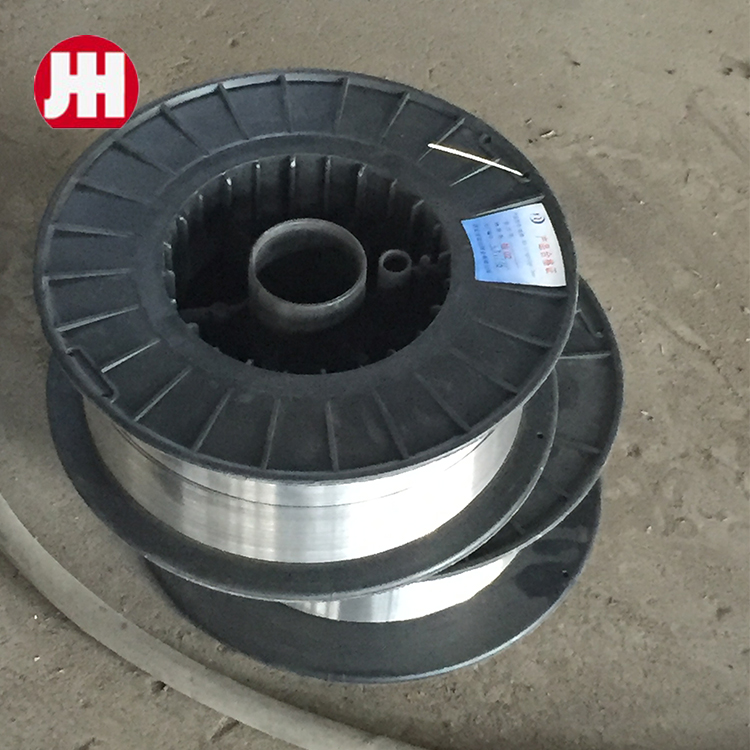

welding rod e7016 manufacturer

Additionally, E7016 rods are frequently used in the construction and repair of bridges, machinery, and heavy equipment. Their robustness makes them suitable for welding critical components that must endure significant stress and pressure over time.

Leading Manufacturers

Several companies specialize in manufacturing high-quality E7016 welding rods, each offering a range of products tailored to meet different industrial standards

. Some of the most reputable manufacturers include1. Hobart Brothers Known for their innovative welding solutions, Hobart offers a line of E7016 rods that cater to various applications, ensuring reliability and performance.

2. Lincoln Electric Lincoln Electric’s E7016 rods are well-regarded for their consistent quality and are widely used across the industry.

3. ESAB ESAB is another leader in the welding equipment market, providing E7016 rods designed to meet rigorous industrial standards.

4. American Welding Society (AWS) While not a manufacturer, AWS sets the standards for welding materials, ensuring that products like the E7016 rod meet industry requirements for quality and performance.

Conclusion

The E7016 welding rod represents a reliable and versatile choice for professionals in the welding industry. Its robust composition, coupled with the ability to perform well across diverse applications, makes it a preferred option for those seeking quality and strength in their welds. By selecting reputable manufacturers and understanding the unique properties of the E7016 rod, welders can ensure the success of their projects and achieve superior results.

-

High-Performance Hard Facing Welding Rod – Durable & Wear-Resistant Electrodes for Industrial UseNewsJul.05,2025

-

Simple Welding Rods – High Quality Arc & Aluminium Welding Rods Wholesale Reliable Stick Welding Rods ManufacturersNewsJul.05,2025

-

3.2mm 7018 Welding Electrode Wholesale Supplier in China Factory Direct Price & High QualityNewsJul.04,2025

-

Stainless Steel Welding Rods for Sale – High Quality 7018 Welding Rods SupplierNewsJul.04,2025

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025