Wholesale CO2 MIG Wire - High Quality & Competitive Prices

Understanding Wholesale CO2 MIG Wire A Comprehensive Overview

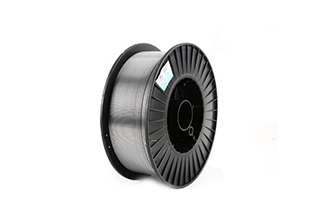

In the world of welding, CO2 MIG (Metal Inert Gas) wire plays a crucial role in various applications, ranging from industrial fabrication to artistic metalworking. The demand for quality welding supplies has led to an increase in wholesale options, making it more accessible for businesses and individual welders alike to source their materials at competitive prices.

Understanding Wholesale CO2 MIG Wire A Comprehensive Overview

When purchasing CO2 MIG wire in wholesale quantities, it is essential to consider various factors that can impact the quality of the weld. The diameter of the wire is a significant determinant; common sizes range from 0.023 inches to 0.045 inches. Welders should select the appropriate diameter based on the thickness of the material being welded. Thinner materials generally require a smaller diameter wire, while thicker materials benefit from a larger diameter for optimal penetration.

wholesale co2 mig wire

Another crucial aspect is the wire’s composition and its suitability for specific welding applications. Different coatings and alloying elements can influence the wire’s performance, including its ability to resist oxidation and maintain strength under high temperatures. Wholesale suppliers should provide detailed information about the wire's specifications and certifications to ensure that welders can make informed choices based on their project requirements.

Moreover, cost is an important consideration when sourcing wholesale CO2 MIG wire. Buying in bulk typically leads to significant savings, but welders must also be wary of compromising on quality. It is advisable to choose reputable suppliers known for their reliability and product quality rather than solely opting for the lowest price.

In conclusion, wholesale CO2 MIG wire is an essential component for welders seeking to achieve high-quality welds in various applications. By understanding the specifications, choosing the right diameter and composition, and selecting reputable suppliers, both businesses and individual welders can optimize their welding processes while managing costs effectively. As the industry continues to evolve, staying informed about the latest trends and materials in welding will ensure success in this ever-demanding field.

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025