Notícias

-

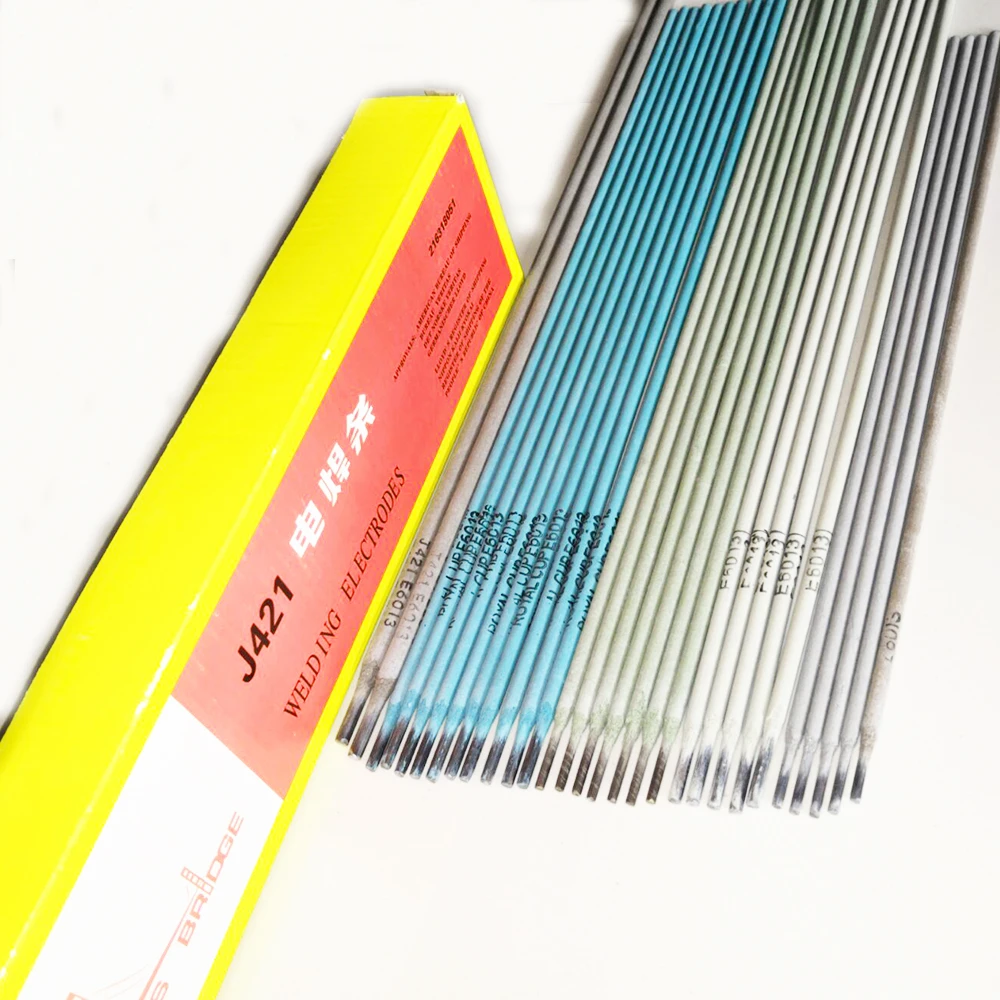

When it comes to welding, choosing the right materials is crucial for achieving strong and durable welds. In this article, we will explore the exceptional qualities of 6013 welding rods and E6013 electrodes, which are widely regarded as the perfect welding solution for various applications.Consulte Mais informação

When it comes to welding, choosing the right materials is crucial for achieving strong and durable welds. In this article, we will explore the exceptional qualities of 6013 welding rods and E6013 electrodes, which are widely regarded as the perfect welding solution for various applications.Consulte Mais informação -

Mig and flux core welders are popular welding machines used in various industries. Mig welding, also known as Gas Metal Arc Welding (GMAW), involves feeding a wire electrode through a welding gun and creating an arc between the electrode and the workpiece. Flux core welding, on the other hand, uses a hollow wire electrode filled with flux to create the arc.Consulte Mais informação

Mig and flux core welders are popular welding machines used in various industries. Mig welding, also known as Gas Metal Arc Welding (GMAW), involves feeding a wire electrode through a welding gun and creating an arc between the electrode and the workpiece. Flux core welding, on the other hand, uses a hollow wire electrode filled with flux to create the arc.Consulte Mais informação -

Mig (Metal Inert Gas) welding has become increasingly popular in various industries due to its efficiency and versatility. One of the key components in Mig welding is the Mig wire, which comes in various types, including Mig copper wire and copper-coated Mig wire. In this article, we will delve into the characteristics, applications, and benefits of these two types of Mig wires.Consulte Mais informação

Mig (Metal Inert Gas) welding has become increasingly popular in various industries due to its efficiency and versatility. One of the key components in Mig welding is the Mig wire, which comes in various types, including Mig copper wire and copper-coated Mig wire. In this article, we will delve into the characteristics, applications, and benefits of these two types of Mig wires.Consulte Mais informação -

Before buying one, make sure your welding current is supported by your welding rods.Consulte Mais informação

Before buying one, make sure your welding current is supported by your welding rods.Consulte Mais informação -

In the bustling shipyard, welding tasks are not uncommon; nonetheless, they demand an unwavering commitment to safety protocols to prevent tragedies.Consulte Mais informação

In the bustling shipyard, welding tasks are not uncommon; nonetheless, they demand an unwavering commitment to safety protocols to prevent tragedies.Consulte Mais informação -

The electrode coating refers to the coating layer applied to the surface of the welding core.Consulte Mais informação

The electrode coating refers to the coating layer applied to the surface of the welding core.Consulte Mais informação -

The selection principle of welding rod plays a crucial role in welding engineering, as it directly affects the quality, performance, economy, and feasibility of welding joints and welding processes. The following are the principles for selecting welding rods summarized from multiple perspectives.Consulte Mais informação

The selection principle of welding rod plays a crucial role in welding engineering, as it directly affects the quality, performance, economy, and feasibility of welding joints and welding processes. The following are the principles for selecting welding rods summarized from multiple perspectives.Consulte Mais informação -

As a key material in welding processes, welding rods have a series of significant characteristics that not only reflect their important role in the welding process, but also determine their wide applicability in different application fields. The following is a detailed explanation of the characteristics of welding rods.Consulte Mais informação

As a key material in welding processes, welding rods have a series of significant characteristics that not only reflect their important role in the welding process, but also determine their wide applicability in different application fields. The following is a detailed explanation of the characteristics of welding rods.Consulte Mais informação -

Carbon steel welding wire, as a widely used welding material, has multiple significant characteristics that together ensure its superior performance and reliability in various welding scenarios. The following is an overview of the main characteristics of carbon steel welding wire.Consulte Mais informação

Carbon steel welding wire, as a widely used welding material, has multiple significant characteristics that together ensure its superior performance and reliability in various welding scenarios. The following is an overview of the main characteristics of carbon steel welding wire.Consulte Mais informação -

Copper coated welding wire, as an important welding material, has significant characteristics and a wide range of application fields. The following is a detailed explanation of its characteristics and application areas.Consulte Mais informação

Copper coated welding wire, as an important welding material, has significant characteristics and a wide range of application fields. The following is a detailed explanation of its characteristics and application areas.Consulte Mais informação -

As the core material in welding processes, welding rods have a wide range of applications, covering almost all industries that require metal connections. The following is a detailed explanation of the application fields of welding rods.Consulte Mais informação

As the core material in welding processes, welding rods have a wide range of applications, covering almost all industries that require metal connections. The following is a detailed explanation of the application fields of welding rods.Consulte Mais informação -

Carbon steel welding wire, as a key material in welding processes, has a wide range of applications, covering multiple important industries. The following is an overview of the main application areas of carbon steel welding wire.Consulte Mais informação

Carbon steel welding wire, as a key material in welding processes, has a wide range of applications, covering multiple important industries. The following is an overview of the main application areas of carbon steel welding wire.Consulte Mais informação