Welding Rod Production A Look at the 1/8 6010 Process and Manufacturers

The Importance of Choosing the Right Welding Rod Manufacturer A Focus on 1/8% 2060 10 Welding Rods

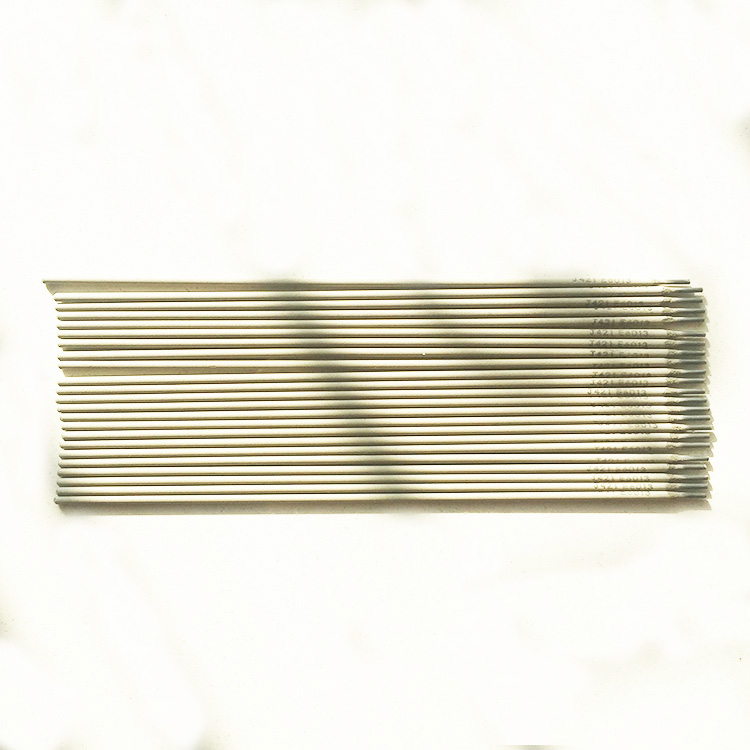

When it comes to welding, the quality of materials used is paramount for achieving strong, durable joints. One essential component in the welding process is the welding rod, which serves as the filler material during arc welding. Among the various types of welding rods available, the 1/8% 2060 10 welding rod has gained popularity for its unique properties and versatility. This article explores the significance of selecting a reputable welding rod manufacturer and the benefits of using 1/8% 2060 10 welding rods.

Understanding 1/8% 2060 10 Welding Rods

The designation 1/8% 2060 10 refers to specific characteristics of the welding rod. The 1/8% indicates the diameter of the rod, which is a vital aspect in matching it to the welding application. The 2060 represents the tensile strength and chemical composition, generally designed for welding low-alloy steel, which is critical in applications such as construction, automotive, and energy sectors. Finally, the 10 symbolizes the rod's classification, indicating its usability and performance under different conditions.

The Role of Quality in Welding Rod Manufacturing

The effectiveness of welding rods relies heavily on the manufacturer’s expertise and quality control processes. Welding rod manufacturers must adhere to strict industry standards to ensure their products are safe and effective. Quality materials and production methods are essential not just for the performance of the welding rod but also for the safety of the welders and the integrity of the structure being worked on.

Benefits of Selecting a Reliable Manufacturer

1. Consistent Quality A reputable manufacturer will have stringent quality control measures in place. This ensures that every batch of welding rods meets the necessary specifications and standards. Consistent quality is crucial for projects requiring precise work, as any inconsistency can lead to weak joints or weld failures.

2. Technical Support Established manufacturers often provide extensive technical support and resources for their products. This can include guidance on proper usage, storage, and best practices, which are invaluable for both novice and experienced welders alike.

1/8 6010 welding rod manufacturer

3. Innovative Solutions Leading manufacturers are often at the forefront of innovation in welding technology. They frequently invest in research and development to produce new materials and coatings that enhance performance. Choosing a manufacturer with a solid reputation for innovation can give welders access to the latest advancements in the field.

4. Customization Options Different welding projects may require specialized rods. Reputable manufacturers often offer customization options to meet specific client needs. Whether it’s adjusting the chemical composition or developing rods that perform better in certain environmental conditions, a good manufacturer can tailor products to fit various applications.

5. Reliable Supply Chain Working with a reliable manufacturer ensures a steady supply of welding rods. This is particularly important for large projects where delays can lead to increased costs and extended timelines. A dependable supplier can provide a consistent inventory, ensuring welders have what they need when they need it.

Selecting the Right Welding Rod Manufacturer

When choosing a manufacturer for 1/8% 2060 10 welding rods, consider factors such as

- Industry Reputation Look for manufacturers with a strong reputation in the welding industry, supported by customer reviews and testimonials. - Certifications Verify that the manufacturer adheres to industry standards and possesses the necessary certifications. - Experience Established manufacturers with years of experience tend to understand the nuances of different welding applications better. - Product Range A diverse product range may indicate a commitment to quality and innovation.

Conclusion

Selecting the right welding rod manufacturer is crucial for achieving the best results in any welding project. The 1/8% 2060 10 welding rods represent an excellent choice for various applications, but their effectiveness is contingent upon using high-quality rods from a reputable manufacturer. By prioritizing quality, innovation, and reliability, welders can ensure that their projects are successful and structurally sound. Investing time in choosing the right manufacturer is an investment in the safety and efficiency of the welding process.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025