3.25mm welding electrodes manufacturers

Exploring the World of 3.25mm Welding Electrodes Manufacturers and Their Significance

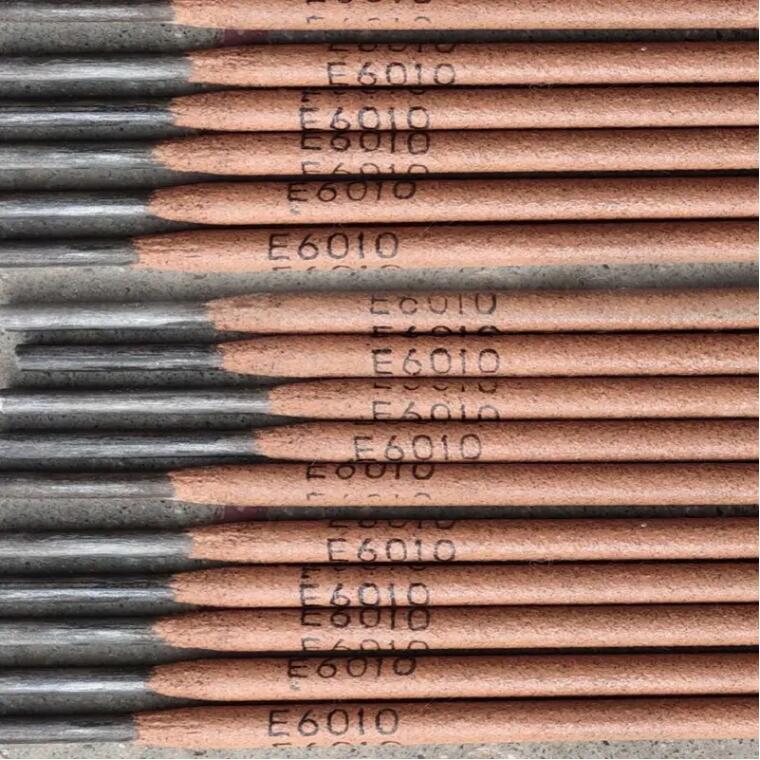

Welding is a crucial process in various industries, forming the backbone of construction, manufacturing, and repair sectors. Within this domain, welding electrodes play a vital role in determining the quality and efficiency of the welding process. Among the various types and sizes of welding electrodes, the 3.25mm electrode is particularly significant due to its versatility and effectiveness in a wide range of welding applications. This article explores the importance of 3.25mm welding electrodes, their manufacturing process, and notable manufacturers in the industry.

Importance of 3.25mm Welding Electrodes

The 3.25mm welding electrode is a popular choice for many welders due to its balanced diameter, which allows it to work effectively with different types of welding materials and setups. This size is particularly favored for medium to heavy welding tasks, as it provides a good combination of current-carrying capacity and stability during the welding process. The versatility of 3.25mm electrodes makes them suitable for welding various materials, including carbon steel, stainless steel, and other alloys.

In addition to their mechanical properties, 3.25mm welding electrodes are beneficial for their ease of use. Welders appreciate that they require less manipulation compared to smaller electrodes, allowing for greater efficiency and superior weld quality. These electrodes also provide excellent penetration, which is essential for achieving strong, durable welds that can withstand significant stress.

The Manufacturing Process

The manufacturing process of 3.25mm welding electrodes involves several critical steps to ensure high quality and performance. It typically begins with the selection of raw materials, which must be of high purity and precise chemical composition. Common materials used in the production of welding rods include copper-coated steel and various alloying elements, depending on the specific characteristics desired in the final product.

Once the raw materials are chosen, they undergo a process known as extrusion, where the materials are heated and forced through a die to achieve the desired diameter. For 3.25mm electrodes, careful control of the extrusion process is crucial to maintain consistency in diameter and prevent defects.

After extrusion, the electrodes are coated with a protective layer that aids in stability during welding, improves arc performance, and helps to prevent oxidation. The coating material can vary depending on the type of welding being performed and the specific properties desired in the final weld. The coated electrodes are then subjected to rigorous quality control measures, including tensile testing, bend testing, and metallurgical analysis, to ensure they meet industry standards.

3.25mm welding electrodes manufacturers

Notable Manufacturers of 3.25mm Welding Electrodes

Several manufacturers have established a strong reputation for producing high-quality 3.25mm welding electrodes. Among them are

1. Lincoln Electric Known for their innovation and commitment to quality, Lincoln Electric produces a wide range of welding electrodes, including 3.25mm options suitable for various applications.

2. ESAB With a strong focus on research and development, ESAB offers numerous welding products, including 3.25mm electrodes designed to meet the needs of modern welding professionals.

3. Miller Electric This company is recognized for its superior welding equipment and electrodes, with a selection that includes high-quality 3.25mm welding rods tailored for different environments and materials.

4. Harris Products Group Specializing in welding and cutting equipment, Harris produces reliable welding electrodes known for their performance and durability, suitable for both amateur and industrial welding.

Each of these manufacturers employs advanced technologies and maintains high standards, ensuring that their 3.25mm welding electrodes meet the demanding requirements of the industry.

Conclusion

3.25mm welding electrodes are a critical component in the welding landscape, favored for their versatility, ease of use, and effectiveness in various applications. Understanding the manufacturing process and the characteristics of these electrodes can help welders choose the right products for their projects. With reputable manufacturers leading the way, the future of 3.25mm welding electrodes looks bright, offering continued innovation and quality to meet the evolving needs of the industry. As welding technology advances, these manufacturers remain key players, ensuring that welders have access to the tools they need for success.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025