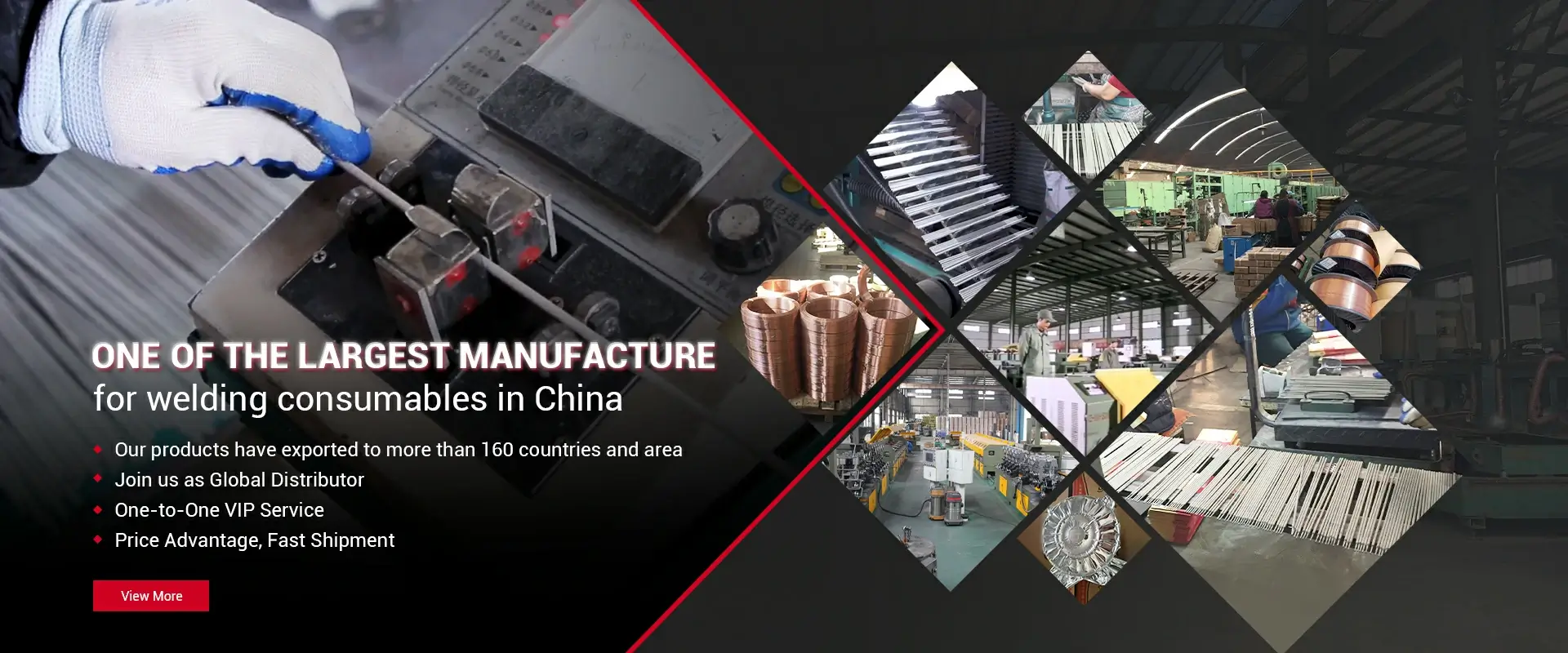

arc copper welding wire factories

The Role of Arc Copper Welding Wire Factories in Modern Industry

In the realm of manufacturing and construction, welding is an essential process that helps to join materials together, especially metals. Among the various types of welding, arc welding stands out for its efficiency and effectiveness. A critical component in the arc welding process is the welding wire, and specifically, copper welding wire has gained immense popularity due to its excellent conductivity and welding characteristics. This article delves into the significance of arc copper welding wire factories, their operations, and their contribution to diverse industries.

Understanding Arc Copper Welding Wire

Arc welding involves using an electric arc to melt and fuse metals. The welding wire acts as both an electrode and a filler material. Copper welding wires are known for their superior conductivity, making them ideal for applications that require electrical conductivity and thermal resistance. Industries that rely heavily on arc copper welding include automotive, aerospace, construction, and various heavy machinery sectors.

The Manufacturing Process

The production of arc copper welding wire involves several stages, each meticulously designed to ensure high quality and performance standards. The primary steps include

1. Raw Material Selection The first step involves sourcing high-grade copper and alloy materials, which are crucial for creating wires that meet industry specifications. The purity of copper significantly affects the performance of the welding wire.

2. Melting and Casting The selected copper undergoes melting in industrial furnaces before being cast into shapes suitable for further processing. This phase is crucial as it impacts the wire's structural integrity.

3. Drawing and Annealing After casting, the copper is drawn into thin wires through a series of dies. This process is followed by annealing, which involves heating the wire to relieve stresses and improve ductility, allowing for better handling during welding.

arc copper welding wire factories

4. Coating and Finishing Many arc copper welding wires are coated with materials that enhance performance, such as flux or additional alloys. The coating helps in improving arc stability and providing better protection against oxidation during the welding process.

5. Quality Control Stringent quality control measures are in place throughout the production cycle. Factories conduct tests for tensile strength, conductivity, and adhesion to ensure the wires meet the required international standards.

Economic Impact of Arc Copper Welding Wire Factories

Arc copper welding wire factories play a pivotal role in the economy. These factories not only provide jobs but also contribute to the economic robustness of the regions in which they operate. By supplying high-quality welding wire, these factories support a multitude of industries ranging from construction to electronics, promoting infrastructural development and manufacturing growth.

Moreover, the rise in automation and advanced technologies in these factories enhances productivity. With the integration of smart manufacturing techniques, factories can produce wires faster and with greater precision, thereby reducing costs and increasing output.

Environmental Considerations

As with any industrial operation, sustainability is an important consideration for arc copper welding wire factories. Several initiatives are being adopted to minimize environmental impact. These include recycling copper materials, utilizing energy-efficient processes, and reducing waste through better production practices.

Conclusion

In conclusion, arc copper welding wire factories are indispensable in today’s industrial landscape. Their methodologies not only advocate for technological advancements in welding but also emphasize quality and efficiency. As industries evolve and demand for better materials increases, the role of these factories will undoubtedly remain critical, shaping the future of welding and manufacturing practices worldwide. The blend of superior product offerings and sustainable practices positions arc copper welding wire factories as leaders in both innovation and responsibility, driving progress in various sectors globally.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025