China 7018 Welding Electrodes and Rods for Reliable Fabrication and Construction Projects

The Importance of China 7018 Welding Rods and Electrodes in Modern Welding Applications

Welding, a fundamental process in metal fabrication, plays a crucial role across various industries, from construction to automotive manufacturing. Among the myriad of welding consumables available, the China 7018 welding rods and electrodes stand out for their unique properties and versatility. This article explores the significance of these welding rods, their applications, benefits, and the reasons behind their widespread adoption in modern welding practices.

Understanding China 7018 Welding Rods

The designation 7018 in welding terminology refers to a specific type of electrode. The 70 indicates a minimum tensile strength of 70,000 psi, while the 18 signifies that the electrode has a composition with an iron powder coating and is designed for use in both AC and DC applications. These rods are primarily composed of low hydrogen content, making them particularly effective in reducing the risk of porosity in the welds, ensuring cleaner and stronger joints.

One of the standout features of 7018 electrodes is their low hydrogen levels. This is critical because hydrogen can lead to cracking in metals, particularly in high-strength steels. The use of low hydrogen electrodes minimizes this risk, making 7018 rods ideal for welding critical applications where reliability is paramount, such as in pressure vessels, pipelines, and structural joints.

Applications in Various Industries

China 7018 welding rods are incredibly versatile and are used across numerous industries. In construction, these rods are often employed to weld structural steel components, ensuring the integrity of buildings, bridges, and other infrastructure. The automotive industry also benefits from the use of 7018 electrodes, as they provide strong welds necessary for chassis and body assembly.

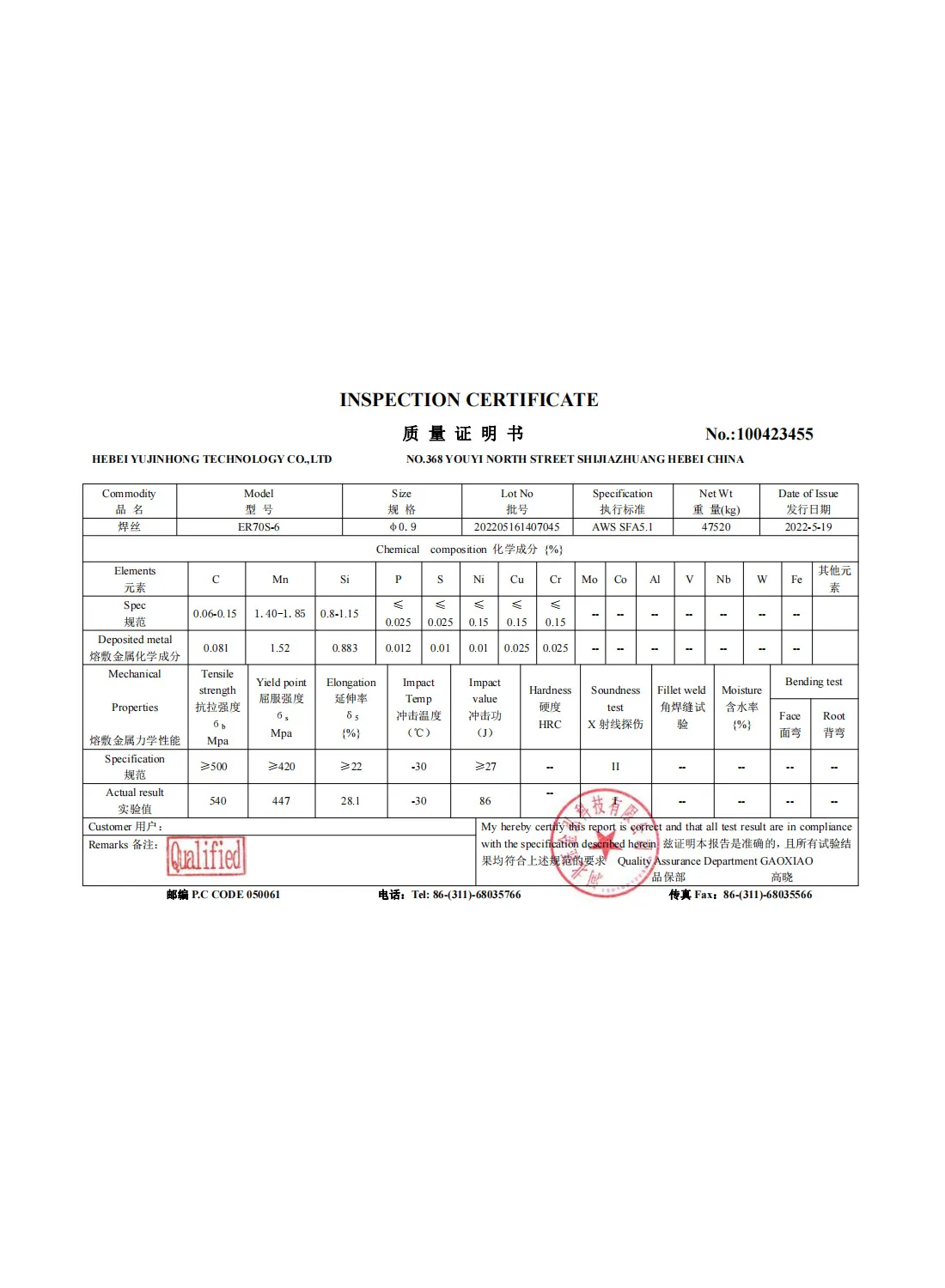

china 7018 welding rods electrodes

Furthermore, in shipbuilding and manufacturing of heavy machinery, where high tensile strengths and durability are essential, 7018 electrodes are preferred. Their ability to perform well in different positions, including flat, horizontal, and overhead, enhances their utility across various welding scenarios.

Advantages of Using China 7018 Welding Rods

The advantages of using China 7018 welding rods are multifaceted. Firstly, the low hydrogen content significantly reduces the likelihood of hydrogen-induced cracking, resulting in more durable welds. Secondly, these electrodes provide excellent arc stability, allowing for smoother welds with less spatter, which can save time on post-weld cleanup and reduce material waste.

Additionally, 7018 rods exhibit good penetration, which is vital for achieving strong bonds between base metals. They also demonstrate good mechanical properties after welding, ensuring that joints retain their strength and ductility over time.

Another noteworthy advantage of 7018 rods is their ease of use. They are suitable for both novice and experienced welders, as their forgiving nature allows for a wider range of operational parameters. This accessibility helps in training new welders, making them an integral part of many welding operations.

Concluding Thoughts

In conclusion, China 7018 welding rods and electrodes represent a significant advancement in welding technology, offering a combination of strength, versatility, and ease of use. They are an essential tool across various industries, providing reliable solutions for critical welding applications. As industries continue to evolve, the demand for high-quality welding consumables like 7018 is expected to grow, making it a cornerstone of modern welding practices. For anyone involved in metal fabrication, understanding the importance of these welding rods is essential for achieving high-quality, durable welds that stand the test of time.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025