china co2 welding wire factory

The Rising Demand for CO2 Welding Wire in China The Role of Local Factories

As industrialization continues to evolve, the demand for high-quality welding materials has surged dramatically across various sectors, particularly in construction, automotive, and manufacturing. Among the key players in this market is CO2 welding wire, a popular choice for its versatility, efficiency, and cost-effectiveness. In China, local factories have emerged as significant contributors to the global supply of CO2 welding wire, amplifying the nation's presence as a manufacturing powerhouse.

Understanding CO2 Welding Wire

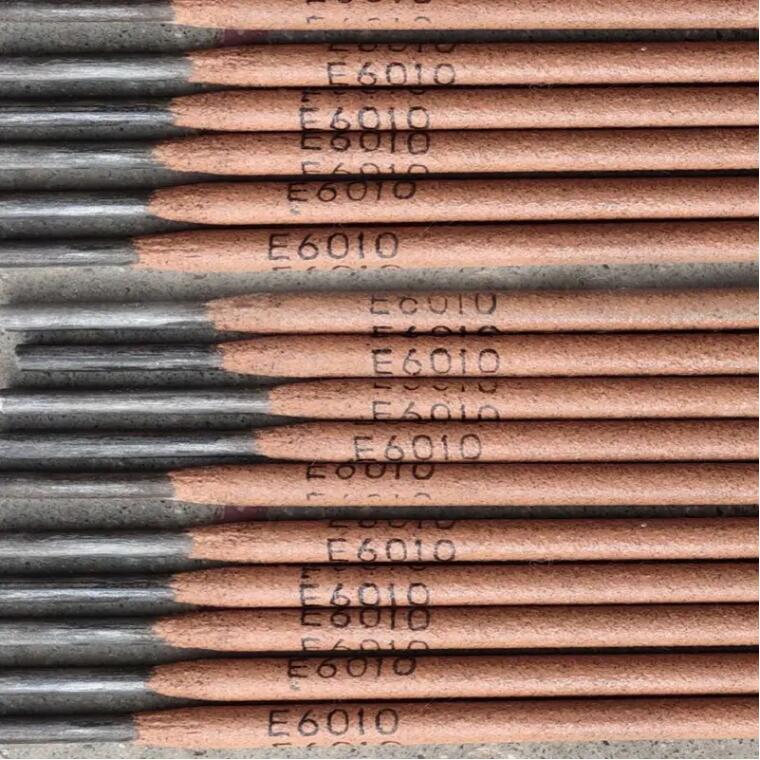

CO2 welding wire, also known as carbon dioxide welding wire, is primarily used in gas metal arc welding (GMAW) processes. This type of welding is favored for its ability to produce strong, clean welds with a minimal amount of post-weld cleanup. The wire itself is composed of a metal core surrounded by a flux coating, enhancing protection during the welding process by preventing oxidation and contamination. One of the main advantages of CO2 welding is its ability to weld through various thicknesses of materials, making it effective for a range of applications.

The Significance of Local Factories

China's investment in manufacturing infrastructure has paved the way for numerous factories dedicated to producing CO2 welding wire. These plants are equipped with state-of-the-art technology and skilled labor, ensuring that the products meet global standards for quality and performance. Furthermore, the ability to produce at a large scale allows these factories to offer competitive pricing, making their products attractive to both domestic and international markets.

Economic Impact

The CO2 welding wire industry has a substantial economic impact in China. As factories ramp up production to meet the increasing demand, they create numerous job opportunities for skilled workers. Additionally, the growth of this sector has spawned a network of ancillary industries, from raw material suppliers to logistics providers, further stimulating local economies. The export potential of Chinese-made CO2 welding wire also contributes to the overall economic health of the nation, enhancing its trade balance and fostering international relations.

china co2 welding wire factory

Environmental Considerations

While developing the CO2 welding wire industry, local factories are also becoming more aware of their environmental responsibilities. The welding industry often faces challenges related to air quality and waste management. To address these concerns, many factories are implementing eco-friendly practices, such as reducing emissions and waste through improved production processes and recycling initiatives. By adopting sustainable practices, these factories not only comply with government regulations but also enhance their reputation in the market.

The Future of CO2 Welding Wire Manufacturing in China

Looking forward, the future of CO2 welding wire manufacturing in China appears bright. As industries continue to evolve, there is a growing need for innovative and high-quality welding materials. The ongoing advancements in technology, combined with a skilled workforce, enable local factories to continually improve their production processes and product offerings.

Moreover, with the rise of automation and the digitalization of manufacturing, factories are increasingly leveraging smart technologies to enhance efficiency and reduce costs. This transformation will position them as leaders in the global welding wire market, ensuring their products remain competitive in both price and quality.

Conclusion

In summary, the production of CO2 welding wire in China represents a vital segment of the country's manufacturing landscape. Local factories are not only meeting the rising demand for welding materials but also playing a crucial role in economic growth, employment generation, and sustainable practices. As the industry progresses, it will undoubtedly continue to adapt and thrive, solidifying China's position as a significant player in the global welding wire market. With commitment and innovation, the future for CO2 welding wire manufacturing in China holds great potential.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025