china rod welding stainless steel factories

China Rod Welding Stainless Steel Factories Pioneering Excellence in Manufacturing

In the heart of the Chinese manufacturing industry, stainless steel rod welding factories play a critical role in ensuring the production of high-quality components used across various sectors. As global demand for durable and corrosion-resistant materials rises, China has emerged as a leading hub for stainless steel production and welding. This article explores the significance of rod welding in stainless steel fabrication, the technological advancements in Chinese factories, and the competitive advantages that position them as leaders in the global market.

The Importance of Stainless Steel Rod Welding

Stainless steel is revered for its remarkable properties, including excellent corrosion resistance, durability, and aesthetic appeal. These attributes make it an ideal material for a myriad of applications, from construction to automotive parts and kitchen equipment. Rod welding, particularly in stainless steel fabrication, is integral to creating robust joints that ensure structural integrity and longevity.

In industries such as aerospace, food processing, and medical equipment manufacturing, the quality of welded joints can significantly impact product performance and safety. Therefore, precision in rod welding is essential, and this is where Chinese factories excel. With advanced welding techniques and stringent quality control measures, they produce stainless steel rods that meet international standards.

Technological Advancements

Chinese factories have adopted state-of-the-art technology to enhance their rod welding processes. Automation plays a pivotal role in increasing efficiency and reducing production costs. Robotic welding systems are increasingly common, allowing for localized heating and stress minimization during the welding process. This results in stronger, more consistent welds with a reduced risk of defects.

Moreover, advancements in welding technologies such as Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding have improved the quality and speed of production. TIG welding, in particular, is well-suited for stainless steel due to its precision and ability to produce clean, high-quality welds. Chinese manufacturing facilities have invested heavily in these technologies, ensuring they remain at the cutting edge of the industry.

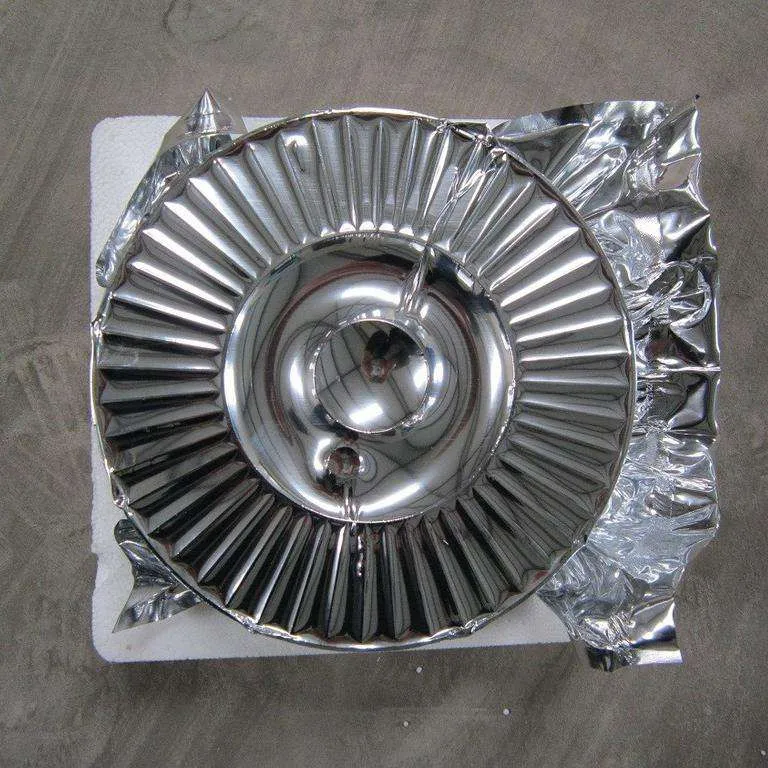

china rod welding stainless steel factories

Workforce Expertise

Beyond technological investment, the skilled workforce in China’s rod welding factories is a crucial asset. Workers undergo extensive training to master various welding techniques and to understand the properties of different grades of stainless steel. Continuous professional development is encouraged to keep pace with technological advancements and evolving industry standards.

Many factories also emphasize collaborative work environments that promote knowledge sharing among engineers and technicians. This culture of teamwork and continuous improvement fosters innovation and enhances overall productivity.

Meeting Global Standards

Chinese stainless steel rod welding factories are committed to quality and compliance with international standards. Many have received certifications such as ISO 9001 for quality management systems, ensuring that their products meet rigorous global benchmarks. This commitment to excellence enables them to compete not only in domestic markets but also on the international stage.

Moreover, China's robust supply chain and logistics infrastructure facilitate timely delivery of products to global customers. This efficient operation model attracts businesses looking for reliable partners in stainless steel fabrication.

Conclusion

The success of China’s rod welding stainless steel factories is a testament to the integration of technology, skilled labor, and stringent quality control. As global industries continue to demand high-quality stainless steel components, these factories are well-positioned to meet the challenges ahead. Their ongoing commitment to innovation and excellence will undoubtedly shape the future of stainless steel manufacturing, making them indispensable players in the global market. The combination of advanced techniques, a dedicated workforce, and a robust regulatory framework ensures that China's stainless steel rod welding capabilities will remain a benchmark worldwide.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025