Solid Welding Wire for CO2 Applications and Its Benefits in Metal Fabrication

The Importance of CO2 Solid Welding Wire in Modern Industries

Welding is a critical process in various industries, including construction, automotive, and shipbuilding, among others. One of the prominent materials used in welding is CO2 solid welding wire, renowned for its versatility and efficiency in different welding applications. This article explores the significance of CO2 solid welding wire, its advantages, and its applications in various sectors.

What is CO2 Solid Welding Wire?

CO2 solid welding wire, often referred to as carbon dioxide solid welding wire, is a type of filler material used in gas metal arc welding (GMAW). This wire is composed primarily of mild steel and is designed to be used with shielding gases, predominantly carbon dioxide or a mixture of argon and carbon dioxide. The process involves feeding the solid wire through a welding gun, where it is melted by an electric arc between the wire and the workpiece, creating a strong bond.

Advantages of CO2 Solid Welding Wire

1. Cost-Effectiveness One of the most significant advantages of CO2 solid welding wire is its affordability. Compared to other welding materials, CO2 wire offers a budget-friendly solution without compromising on quality. This cost efficiency is particularly beneficial for large-scale projects where thousands of meters of welding wire may be required.

2. Good Penetration CO2 solid welding wire provides excellent penetration into the base material, making it suitable for thicker metals. This deep penetration results in stronger welds and reduced likelihood of defects, which is vital for structural integrity.

3. Ease of Use This type of welding wire is relatively easy to handle and can be used with various welding machines. It allows for high deposition rates and is suitable for both novice and experienced welders, facilitating a smoother learning curve.

4. Versatility CO2 solid welding wire is versatile and can be used for welding a variety of metals, including carbon steel and low-alloy steels. This adaptability makes it a popular choice across different industries.

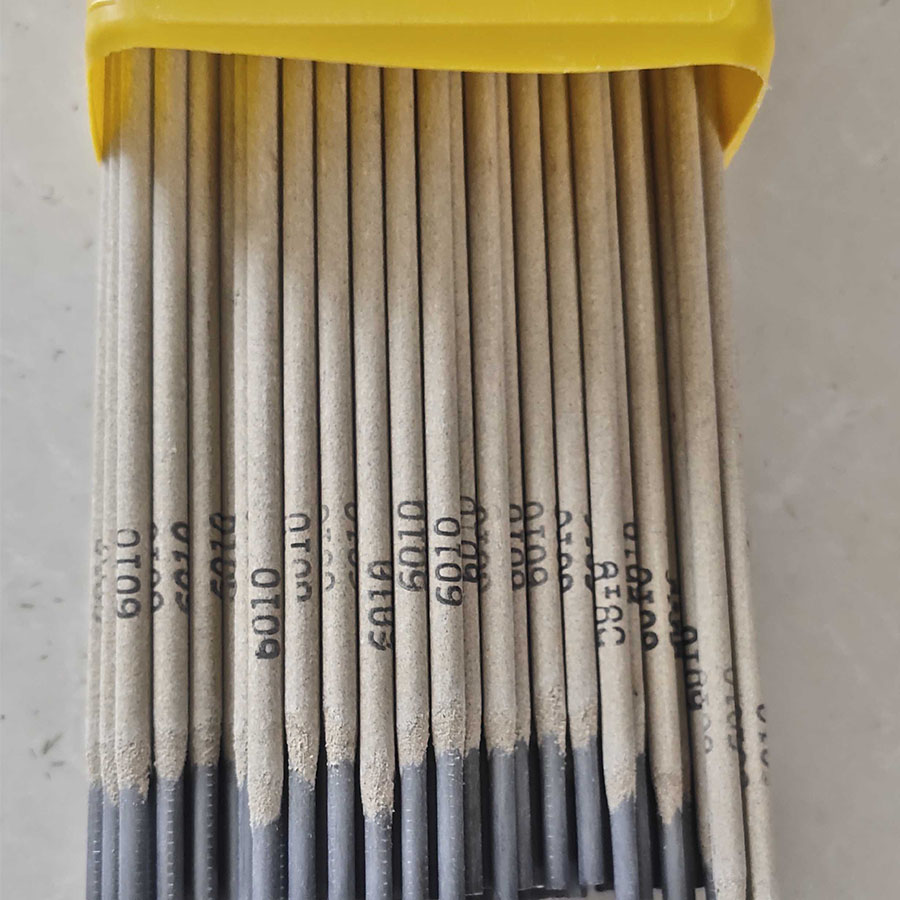

co2 solid welding wire

5. Fine Welding Finish The use of CO2 solid welding wire often results in a fine welding finish with minimal spatter. This is particularly advantageous in applications where aesthetic appearance is important.

Applications of CO2 Solid Welding Wire

CO2 solid welding wire is widely utilized across various sectors due to its numerous advantages. Some prominent applications include

1. Automotive Industry In the automotive sector, CO2 solid welding wire is extensively used for assembling vehicle bodies, frames, and components. The strong welds formed using this wire contribute to safety and durability, essential features for vehicles.

2. Construction The construction industry often employs CO2 solid welding wire for structural steel fabrication. Beams, columns, and metal connections require robust welding, making this wire an optimal choice for such applications.

3. Shipbuilding Ships often encounter harsh conditions; hence, strong and reliable welding is crucial. CO2 solid welding wire is used to weld various components of ships, ensuring safety and longevity.

4. Manufacturing In manufacturing environments, CO2 solid welding wire is utilized in the production of machinery and equipment. This wire’s ability to join different metal parts efficiently makes it invaluable in diverse manufacturing processes.

Conclusion

CO2 solid welding wire has become a cornerstone in the field of welding, offering numerous advantages that streamline processes and enhance the quality of welds. Its cost-effectiveness, ease of use, and versatility make it an essential material across various industries. As technology advances, the efficiency and effectiveness of CO2 solid welding wire are expected to evolve further, solidifying its role in modern welding applications. By choosing CO2 solid welding wire, industries ensure they are equipping themselves with a reliable solution capable of meeting the demands of contemporary welding tasks.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025