e71t gs mig wire manufacturers

Understanding E71T GS MIG Wire Manufacturers

Welding is a crucial process in various industries, including construction, automotive, shipbuilding, and manufacturing. One of the key elements in achieving high-quality welds is the selection of the proper filler material. Among the various types of welding wires available, E71T GS MIG wire has gained significant popularity due to its versatility and ease of use. This article explores E71T GS MIG wire, its applications, and the manufacturers behind this essential welding product.

What is E71T GS MIG Wire?

E71T GS is a type of flux-cored MIG (Metal Inert Gas) welding wire that is known for its excellent performance in welding structures that require high strength and toughness. The E in E71T signifies that it is an electrode, while 71 indicates the minimum tensile strength of the weld metal, which is 71,000 psi. The T denotes that it is a tubular wire, and GS signifies that it is suitable for welding in both gas-shielded and non-gas-shielded applications.

This wire is particularly favored for its ability to create strong, high-quality welds with minimal spatter and a smooth finish. It is suitable for a wide range of base metals, including mild steel and low-alloy steel. Its versatility makes it a go-to choice for many welders in various industries.

Applications of E71T GS MIG Wire

E71T GS MIG wire has a broad array of applications. It is widely used in the construction of heavy equipment, manufacturing of storage tanks, and fabrication of structural steel. Welders often prefer this wire for its ability to perform well in various positions, including flat, horizontal, vertical, and overhead. This adaptability is essential for completing complex welding projects efficiently.

Moreover, E71T GS can be used in both indoor and outdoor environments, making it highly valuable for both workshop and field applications. Its flux-cored design allows for effective welding in adverse weather conditions, which is a significant advantage over solid wires that require shielding gases.

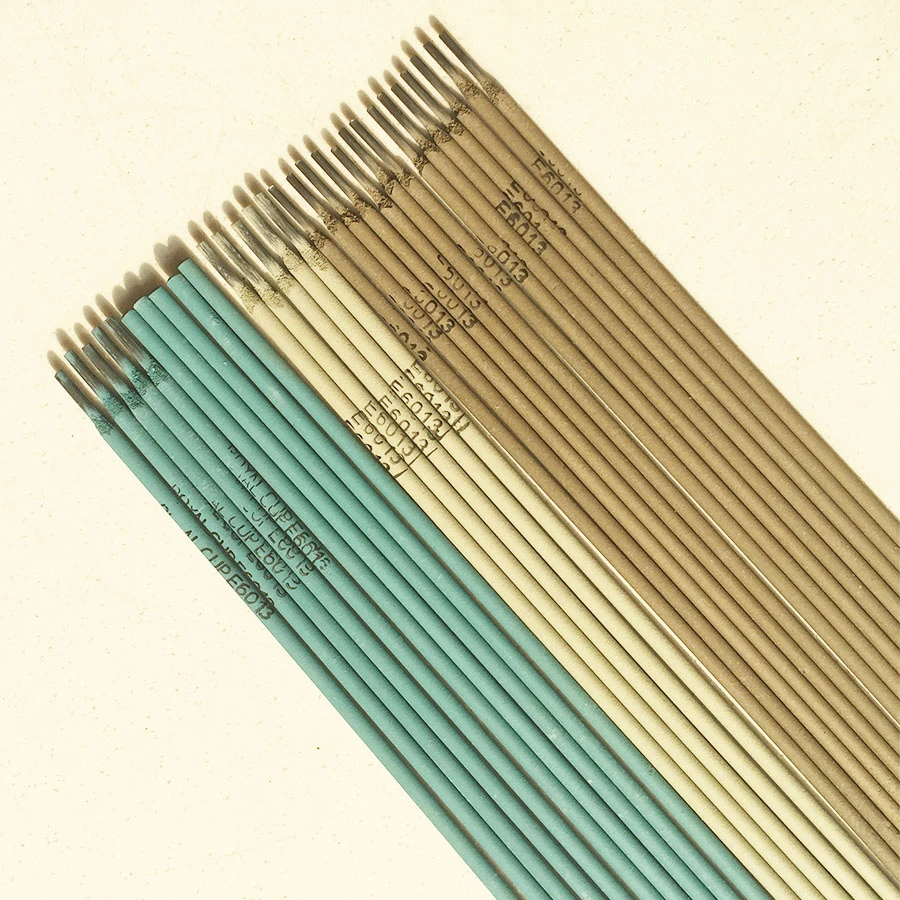

e71t gs mig wire manufacturers

Manufacturers of E71T GS MIG Wire

Several manufacturers have established themselves as leaders in producing E71T GS MIG wire. These companies invest in advanced technology and stringent quality control measures to ensure that their products meet high industrial standards.

1. Lincoln Electric One of the most recognized names in the welding industry, Lincoln Electric produces a range of welding wires, including E71T GS. They focus on innovation and quality, offering products that enhance the efficiency and effectiveness of welding operations.

2. Hobart Brothers Another key player, Hobart Brothers, has a strong reputation for high-performing welding materials. Their E71T GS wire is widely used across various sectors, thanks to its reliability and performance.

3. Esab Known for its cutting-edge welding solutions, Esab manufactures E71T GS MIG wire with a focus on performance in tough conditions. Their products are designed to offer excellent arc stability and reduced spatter.

4. Miller Electric With a commitment to welding excellence, Miller Electric is a trusted source for E71T GS MIG wire. Their products are engineered to meet diverse welding needs, ensuring strong and consistent welds.

Conclusion

E71T GS MIG wire is an essential product for welders looking to achieve high-quality results across various applications. With several reputable manufacturers dedicated to producing this type of welding wire, welders can rely on their quality and performance. As industries continue to evolve, E71T GS MIG wire will remain a key component in the welding toolkit, supporting the development of strong and durable structures.

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025