electrodos 3.25 manufacturer

Understanding Electrodos The Role of Electrode Manufacturers in Modern Technology

Electrodos, commonly referred to as electrodes, play a crucial role in various technological applications, notably in fields such as electronics, electrochemistry, and energy storage. As we examine the landscape of electrode manufacturing, it's important to recognize both the complexities of their production and their impact on innovative solutions in modern technology. With a focus on manufacturers who set high standards, the importance of quality, precision, and ongoing research becomes evident.

What is an Electrode?

An electrode is a conductive material that allows the flow of electric current between the electrode and an electrolyte or another conductive medium. Electrodes are vital components in batteries, fuel cells, electrochemical sensors, and various electronic devices. They can be made from various materials, including metals, carbon, and conductive polymers, depending on their application and required performance characteristics.

The Importance of Electrode Manufacturing

The manufacturing of electrodes is a sophisticated process involving the selection of suitable materials, precise engineering, and quality control. The performance and lifespan of devices rely heavily on the properties of their electrodes. For instance, in batteries, electrodes determine energy density, charge/discharge rates, and overall efficiency. Therefore, manufacturers must not only focus on creating high-quality materials but also adapt to the evolving demands of technology.

Key Factors in Electrode Manufacturing

1. Material Selection The choice of materials directly affects an electrode's performance. For lithium-ion batteries, lithium cobalt oxide and graphite are commonly used. However, manufacturers are continually researching new compounds that can offer better performance, such as silicon-based anodes that promise higher capacities.

electrodos 3.25 manufacturer

2. Production Techniques Advanced manufacturing techniques like sputtering, electrospinning, and additive manufacturing (3D printing) are increasingly employed. These techniques enable precise control over the electrode's microstructure, enhancing performance characteristics such as conductivity and surface area.

3. Quality Control Rigorous testing is essential to ensure that electrodes meet specific standards. Manufacturers implement various quality assurance methods, including electrochemical testing, mechanical durability assessments, and thermal stability checks.

4. Sustainability The push for greener technologies has led manufacturers to explore sustainable practices in electrode production. This includes finding ways to recycle materials, reduce waste, and employ eco-friendly processes in the manufacturing cycle.

The Future of Electrode Manufacturing

Looking to the future, the electrode manufacturing industry is poised for significant advancements driven by current trends in technology. As the demand for batteries increases, especially for electric vehicles (EVs) and renewable energy storage solutions, manufacturers are focusing on innovation. Emerging technologies such as solid-state batteries promise improved safety and efficiency, requiring novel electrode materials and designs.

Furthermore, advancements in nanotechnology are enabling the development of high-performance electrodes with enhanced properties. Researchers are exploring nanoscale materials to increase surface area, improve ion transport, and reduce resistance, thereby delivering better performance in various applications.

Conclusion

In conclusion, the role of electrode manufacturers is pivotal in driving technological innovation across multiple sectors. As we continue to rely on electrochemical systems for everyday applications—from powering our smartphones to enabling sustainable energy solutions—the demand for high-quality electrodes will only grow. Manufacturers who prioritize material research, adhere to stringent quality standards, and embrace sustainable practices will lead the charge into a future where technology continues to evolve in sync with our needs. As the industry advances, staying informed and adaptable will ensure that electrode manufacturers can meet the challenges and opportunities that lie ahead. Through their ongoing efforts, manufacturers not only contribute to the functionality of numerous devices but also play a vital role in paving the way for future technologies that may reshape our world.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

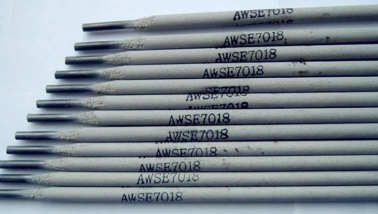

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025