mig flux core welding wire manufacturers

The Evolution and Importance of MIG Flux Core Welding Wire Manufacturers

The Evolution and Importance of MIG Flux Core Welding Wire Manufacturers

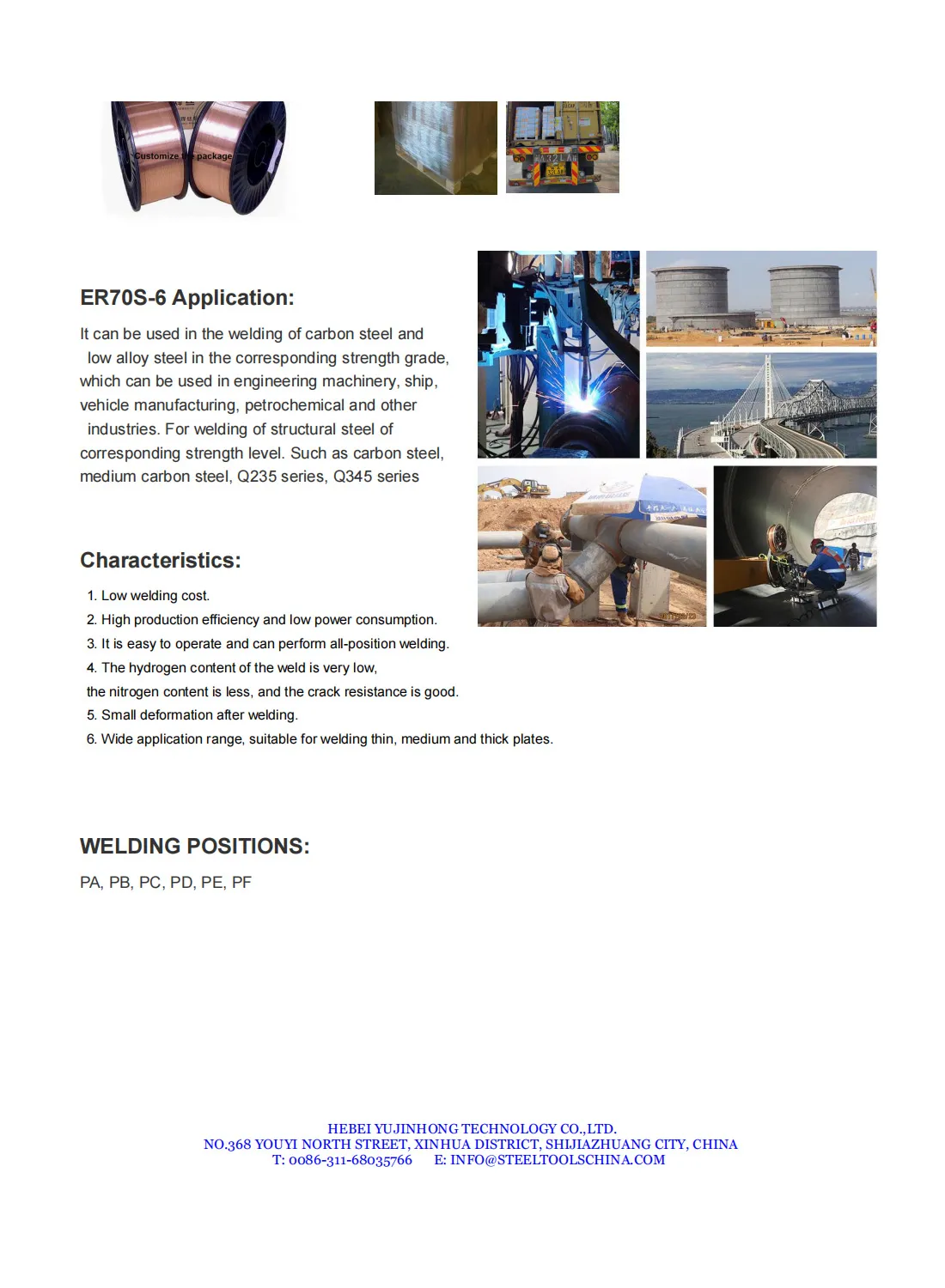

MIG flux core welding wire is designed to facilitate easy and effective welding. Unlike traditional MIG welding that utilizes external shielding gases, flux core welding wire contains a fluxing agent within the core of the wire itself. This agent produces a shielding gas when heated, effectively protecting the molten weld pool from contamination. This feature enables welders to work in diverse weather conditions and on rusted or dirty surfaces, significantly broadening the operational scope for many industries, including construction, automotive, and repair works.

mig flux core welding wire manufacturers

Manufacturers of MIG flux core welding wire face several challenges in ensuring product quality and performance. They must maintain stringent quality control processes to guarantee that their wires meet the necessary industry standards. Factors such as wire diameter, tensile strength, and the composition of the flux are critical in determining the weld quality and overall performance. Therefore, manufacturers invest heavily in research and development to innovate and produce wires that possess superior characteristics, such as better arc stability, reduced spatter, and improved penetration.

Moreover, with the increasing focus on sustainability, many manufacturers are now exploring eco-friendly materials and processes in their production lines. This shift not only helps in reducing the environmental impact of welding operations but also caters to the growing demand for sustainable practices among consumers and industries alike.

In conclusion, the role of MIG flux core welding wire manufacturers is pivotal in the welding industry. Their continuous efforts in enhancing the quality of welding wires while addressing sustainability concerns are instrumental in meeting the evolving demands of various sectors. As technology advances, we can expect further innovations in flux core welding materials, paving the way for improved efficiency and greater versatility in welding applications. This commitment to quality and innovation will undoubtedly shape the future of welding technology, ensuring that it remains a key component in modern manufacturing and construction practices.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025