Jan . 13, 2025 16:48

Back to list

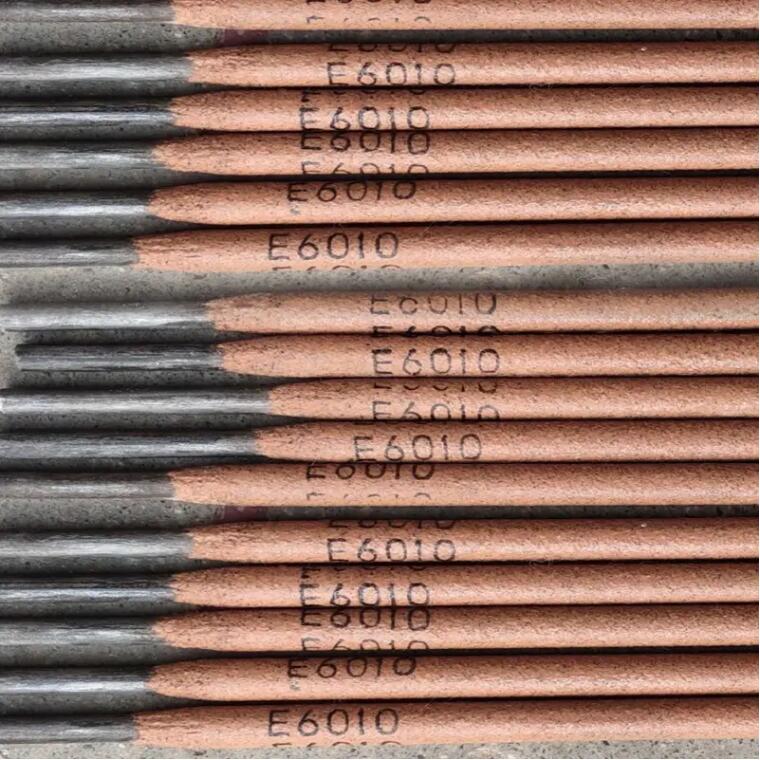

Welding Rods 6010 for welding carbon steel tubes

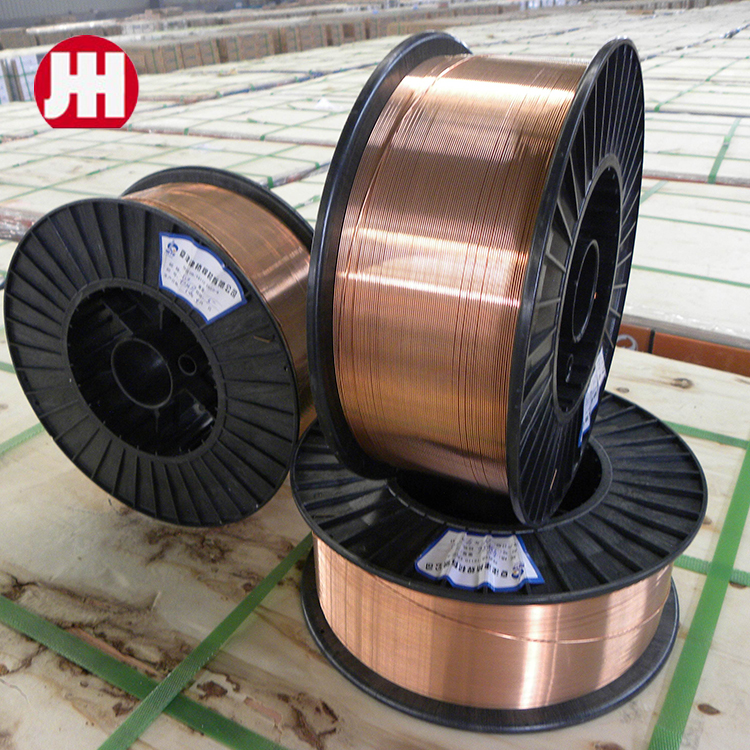

Weld wire, a critical component in the realm of welding and metal fabrication, is more than just a thread of metal—it is a cornerstone of quality output and professional excellence. Understanding the nuances of weld wire can significantly enhance the outcome of a welding project and ensure both safety and durability.

Experiential Insights into Weld Wire Applications Seasoned welders rely on their extensive experience to determine the optimal weld wire for each task. They understand that environmental factors, like humidity and temperature, can affect welding performance and adjust their choice of wire accordingly. For example, flux-cored wires are favored in outdoor settings due to their ability to create a shielding gas that protects the weld pool from atmospheric contamination, ensuring a high-quality weld even in challenging conditions. The Trustworthiness of Weld Wire Manufacturers Trustworthiness in the context of weld wires often boils down to the reputation and quality standards of the manufacturer. Leading manufacturers provide detailed specification sheets with comprehensive information on their wire products, from mechanical properties to chemical composition, enabling users to make well-informed choices. Consistent product quality, certification by recognized international standards, and robust customer support are hallmarks of trustworthy weld wire brands. Experienced welders often testify to the reliability of certain brands after years of consistent performance, underscoring the importance of brand reputation in selecting weld wire. In the demanding field of welding, authoritative knowledge about weld wire can greatly enhance the quality and efficiency of welding projects. By investing time in understanding the different types of wire, their properties, and the contexts in which they excel, both novice and expert welders can achieve superior results. Trustworthy sources and brands further bolster the confidence of users, ensuring that each weld stands the test of time. Ultimately, the mastery of weld wire selection and application not only marks the difference between average and exceptional welding projects but also cements the professional reputation of the welder. The intricate dance between experience, expertise, authoritativeness, and trustworthiness shapes the world of welding, with weld wire as the unsung hero holding everything together.

Experiential Insights into Weld Wire Applications Seasoned welders rely on their extensive experience to determine the optimal weld wire for each task. They understand that environmental factors, like humidity and temperature, can affect welding performance and adjust their choice of wire accordingly. For example, flux-cored wires are favored in outdoor settings due to their ability to create a shielding gas that protects the weld pool from atmospheric contamination, ensuring a high-quality weld even in challenging conditions. The Trustworthiness of Weld Wire Manufacturers Trustworthiness in the context of weld wires often boils down to the reputation and quality standards of the manufacturer. Leading manufacturers provide detailed specification sheets with comprehensive information on their wire products, from mechanical properties to chemical composition, enabling users to make well-informed choices. Consistent product quality, certification by recognized international standards, and robust customer support are hallmarks of trustworthy weld wire brands. Experienced welders often testify to the reliability of certain brands after years of consistent performance, underscoring the importance of brand reputation in selecting weld wire. In the demanding field of welding, authoritative knowledge about weld wire can greatly enhance the quality and efficiency of welding projects. By investing time in understanding the different types of wire, their properties, and the contexts in which they excel, both novice and expert welders can achieve superior results. Trustworthy sources and brands further bolster the confidence of users, ensuring that each weld stands the test of time. Ultimately, the mastery of weld wire selection and application not only marks the difference between average and exceptional welding projects but also cements the professional reputation of the welder. The intricate dance between experience, expertise, authoritativeness, and trustworthiness shapes the world of welding, with weld wire as the unsung hero holding everything together.

Previous:

Latest news

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025