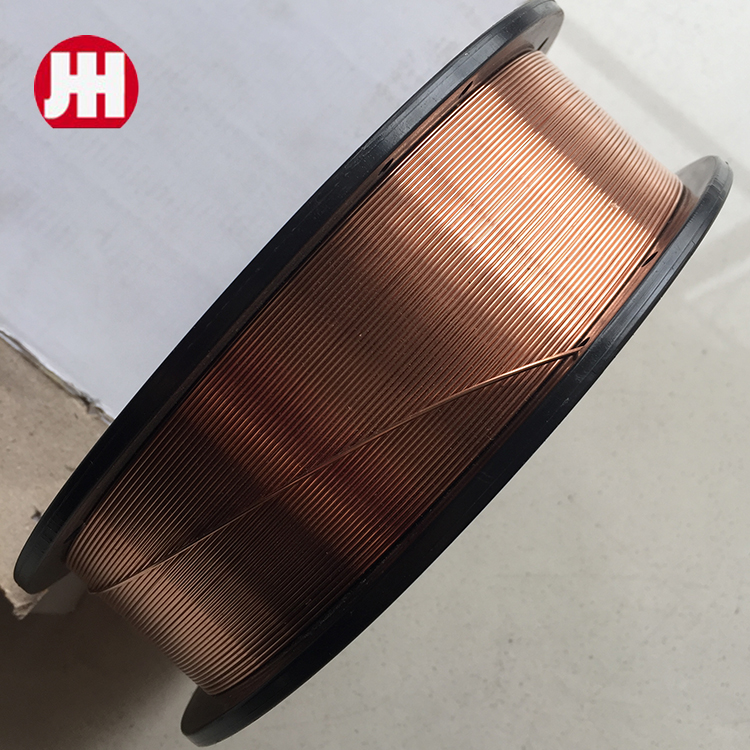

welding wire manufacturer

The Importance of Selecting the Right Welding Wire Manufacturer

When it comes to welding processes, the choice of welding wire is just as critical as the welder’s skill and the equipment used. Welding wire manufacturers play a pivotal role in ensuring that fabricators and welders can achieve high-quality results. Selecting the right manufacturer can significantly influence the productivity, safety, and overall outcomes of welding projects.

Quality Assurance

One of the foremost aspects of a reputable welding wire manufacturer is stringent quality control. High-quality welding wire ensures optimal performance, which directly impacts the integrity of the weld. Manufacturers who adhere to industry standards and certifications, such as ISO 9001, guarantee that their products undergo rigorous testing. This testing includes checks on chemical composition, tensile strength, and usability under various conditions. By consistently delivering quality welding wire, these manufacturers help prevent defects and increase the reliability of the final product.

Product Variety

Welding applications vary greatly, so a good manufacturer should provide a range of welding wires tailored for different processes. From MIG and TIG welding to stick electrodes, each type of wire serves a specific purpose and material compatibility. A reliable manufacturer will offer a diverse array of materials such as stainless steel, aluminum, and carbon steel wires, ensuring that welders can choose the right type for their specific application. Access to various wire options enables welders to work on a broader range of projects without compromising quality.

Technical Support and Expertise

welding wire manufacturer

The complexity of welding technology means that support can be invaluable. Leading welding wire manufacturers often have dedicated technical support teams who can assist customers with any questions regarding product selection, usage, or troubleshooting. They provide insights into the latest techniques and materials, helping customers to optimize their processes. Furthermore, many manufacturers offer training sessions and workshops that can benefit both novice and experienced welders by enhancing their skills and understanding of new products.

Cost-Effectiveness

While price shouldn't be the sole factor in choosing a welding wire manufacturer, it certainly plays a role. High-quality welding wire can be more cost-effective in the long run, as it results in fewer defects and rework costs. By investing in reliable products from a reputable manufacturer, businesses can minimize downtime and waste, thus improving their overall efficiency and profitability.

Sustainability Practices

In recent years, the focus on environmental sustainability has grown significantly. Many welding wire manufacturers are now committed to reducing their carbon footprint through environmentally friendly practices. This includes using recyclable materials, minimizing waste during production, and implementing energy-efficient processes. Companies that prioritize sustainability not only contribute to the health of the planet but also appeal to increasingly eco-conscious consumers.

Conclusion

Choosing the right welding wire manufacturer is essential for anyone involved in welding. By considering factors like quality assurance, product variety, technical support, cost-effectiveness, and sustainability, businesses can ensure they select a partner that meets their needs. The right manufacturer helps ensure that projects are completed safely, efficiently, and to the highest standards, ultimately contributing to the success of the welding industry as a whole. Investing in quality welding wire is not just a procurement decision; it is a step toward achieving excellence in every welding operation.

-

E71TGS Welding Wire High-Strength Flux Core for Durable JointsNewsMay.20,2025

-

High-Strength 3/4 Welding Rod 7016 for Pipe Welding China SupplierNewsMay.20,2025

-

71T1 Flux Cored Wire High-Performance 1.2mm Welding SolutionsNewsMay.20,2025

-

3.25mm Welding Electrodes High-Performance, Durable Wholesale FactoryNewsMay.19,2025

-

AWS A5.1 E6010 Welding Rods Durable All-Position ElectrodesNewsMay.19,2025

-

Wholesale E6013 Welding Electrodes Factories Durable & AffordableNewsMay.18,2025