Wholesale Stainless Steel MIG Welding Wire Suppliers and Manufacturers

Wholesale MIG Wire for Stainless Steel An Overview for Manufacturers

In the world of metalworking and fabrication, the choice of welding materials plays a critical role in ensuring the quality, strength, and durability of the final product. Among these materials, Metal Inert Gas (MIG) welding wire designed specifically for stainless steel has gained significant traction among manufacturers. As industries push for high-performance materials that can withstand diverse environments, wholesale MIG wire for stainless steel emerges as a paramount solution.

Understanding MIG Welding

MIG welding is a popular welding process characterized by the use of a continuous wire electrode that is fed through a welding gun. This process allows for a stable arc and a smooth welding operation. One of the key advantages of MIG welding is its ability to produce high-quality welds with minimal defects, making it an ideal choice for fabricating stainless steel components.

The Importance of Stainless Steel

Stainless steel is renowned for its resistance to corrosion, impressive mechanical properties, and aesthetic appeal. It finds applications across various industries, including construction, automotive, aerospace, and food processing. However, to tap into the full potential of stainless steel, manufacturers must use the right MIG welding wire suited for this material. The quality of the wire significantly influences the welding outcome, making the selection process crucial.

Why Choose Wholesale MIG Wire?

1. Cost Efficiency Purchasing MIG wire in bulk can lower costs substantially. Manufacturers often benefit from wholesale pricing, which can lead to significant savings, particularly for those with large-scale production needs. By sourcing materials at competitive rates, companies can enhance their profit margins while maintaining high-quality production standards.

2. Consistent Quality Reliable wholesale suppliers maintain strict quality control measures to ensure that their MIG wire meets industry standards. This consistency is essential for manufacturers who require welding materials that perform uniformly during the welding process, reducing the likelihood of defects and rework.

3. Variety of Options Wholesale suppliers typically offer a wide range of stainless steel MIG wires, catering to different grades and applications, such as 308L, 309L, and 316L stainless steel. This vast selection allows manufacturers to choose the best wire for their specific needs, ultimately contributing to project success.

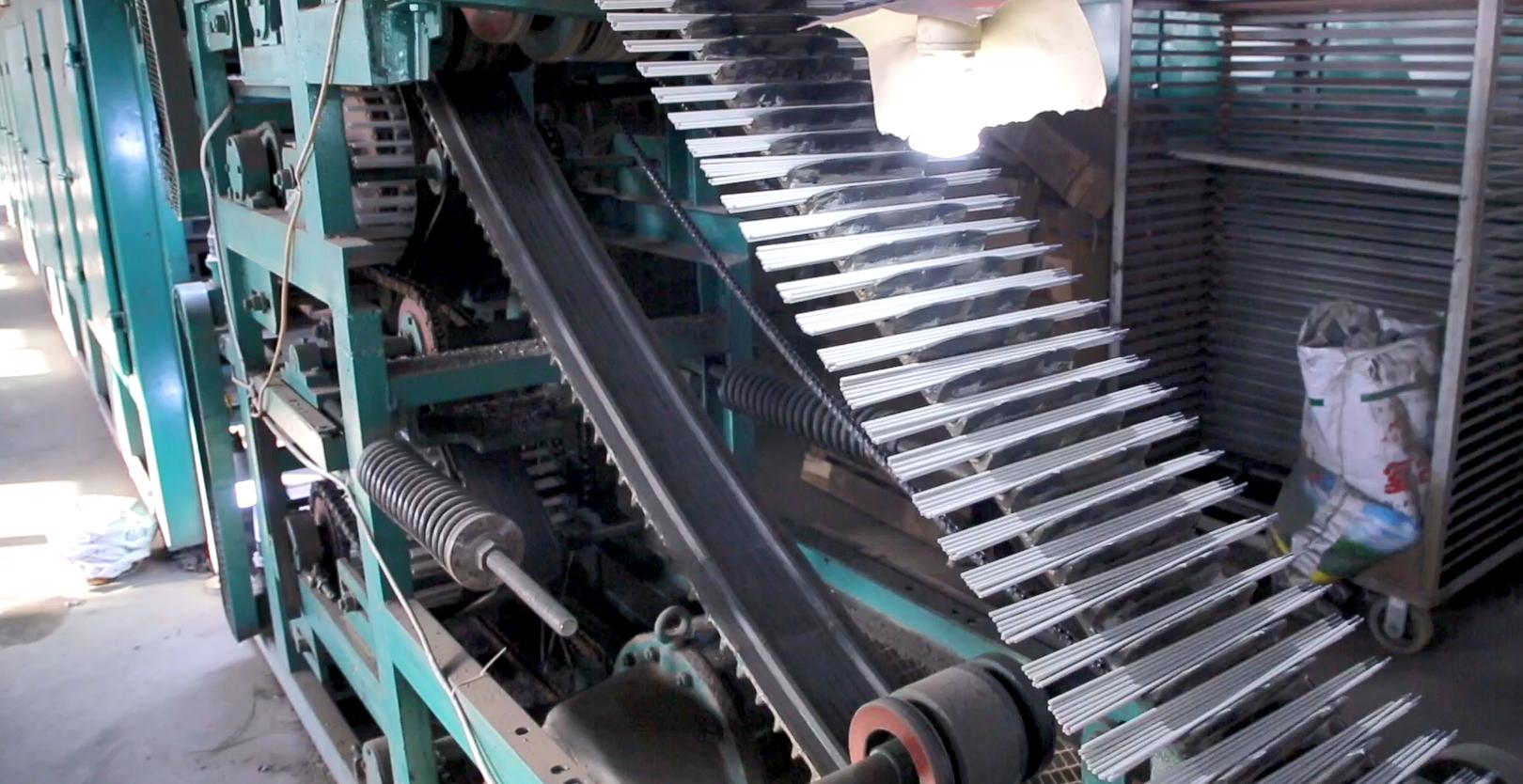

wholesale mig wire for stainless manufacturer

4. Convenience of Supply Establishing a relationship with a wholesale supplier can streamline the procurement process. Regular deliveries, priority access to new products, and reliable customer support can help manufacturers focus on their core operations while ensuring they're never short on essential materials.

Key Considerations for Manufacturers

When sourcing wholesale MIG wire for stainless steel, manufacturers should consider several factors

- Material Composition The chemical make-up of the MIG wire directly affects its performance and compatibility with different stainless steel grades. It’s crucial to select a wire that matches the base metal, ensuring optimal weld integrity and corrosion resistance.

- Wire Diameter The diameter of the MIG wire can influence the welding speed and overall quality of the weld. Manufacturers must select an appropriate diameter based on the specific welding application and material thickness.

- Supplier Reputation Choosing a reputable supplier can significantly impact the quality of the welding wire. It’s vital to research potential suppliers, seek recommendations, and read customer reviews to ensure a reliable partnership.

- Technical Support A supplier that offers technical assistance can be invaluable. Manufacturers often encounter specific challenges during welding processes, and a supplier with expertise can offer guidance on material selection, equipment settings, and troubleshooting.

Conclusion

In conclusion, the wholesale supply of MIG wire for stainless steel presents an excellent opportunity for manufacturers aiming to enhance their welding capabilities while optimizing costs. By understanding the nuances of MIG welding and selecting the right materials from reputable suppliers, manufacturers can ensure high-quality, durable products that meet industry standards. Investing in quality MIG wire is not merely a procurement decision; it's a strategic move that can lead to lasting success in the competitive world of metal fabrication.

-

High-Performance Hard Facing Welding Rod – Durable & Wear-Resistant Electrodes for Industrial UseNewsJul.05,2025

-

Simple Welding Rods – High Quality Arc & Aluminium Welding Rods Wholesale Reliable Stick Welding Rods ManufacturersNewsJul.05,2025

-

3.2mm 7018 Welding Electrode Wholesale Supplier in China Factory Direct Price & High QualityNewsJul.04,2025

-

Stainless Steel Welding Rods for Sale – High Quality 7018 Welding Rods SupplierNewsJul.04,2025

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025