wholesale stainless welding rod 309 suppliers

Wholesale Stainless Welding Rod 309 Suppliers A Comprehensive Guide

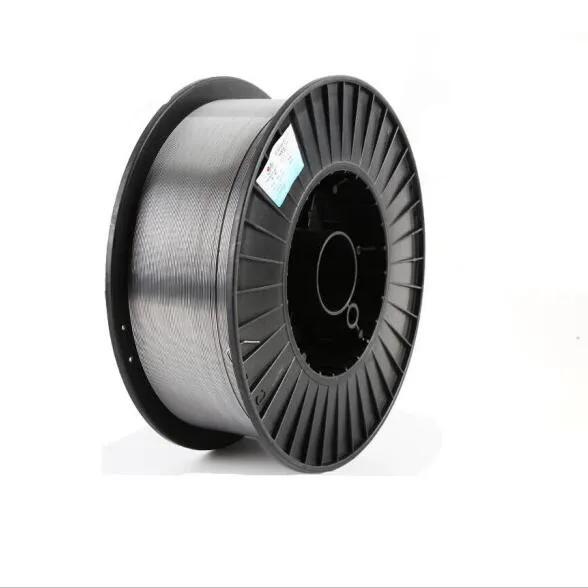

In the realm of metal fabrication and welding, the materials used are crucial for achieving strong, resilient, and high-quality welds. Among these materials, stainless steel welding rods are notable for their versatility and durability, especially the 309 stainless steel welding rod. This article explores the characteristics of 309 welding rods, their applications, and factors to consider when sourcing wholesale suppliers.

Understanding 309 Stainless Steel Welding Rods

309 stainless steel welding rods are primarily composed of chromium and nickel, which provide exceptional corrosion resistance and mechanical strength. These rods are specifically designed for welding dissimilar metals and for applications wherein high-temperature resistance is required. The unique characteristics of the 309 alloy make it ideal for joining stainless steel to carbon steel and for resisting oxidation at elevated temperatures.

Due to its robust properties, the 309 welding rod can withstand thermal cycling and is frequently used in applications within the aerospace and petrochemical industries, as well as in manufacturing high-pressure boilers and furnace parts. The ability to create a strong fusion between metals that have different expansion rates sets 309 welding rods apart from others, making them essential for various industrial processes.

The Importance of Wholesale Suppliers

When sourcing 309 stainless steel welding rods, the choice of supplier can significantly impact the quality of work produced. Wholesale suppliers offer various advantages, including bulk purchasing discounts, a wider selection of products, and the ability to establish long-term relationships that facilitate better service and reliability.

Choosing a reputable wholesale supplier involves several considerations. It is important to assess their experience in the industry, product quality, and customer service. Suppliers that focus on quality assurance and adherence to industry standards ensure that their products will perform effectively in demanding applications. Look for suppliers that provide certification and traceability for their products to guarantee compliance with necessary specifications.

Factors to Consider When Selecting Wholesale Suppliers

wholesale stainless welding rod 309 suppliers

1. Product Quality Ensure the welding rods meet industry standards (such as AWS or ASME certifications). Quality is paramount, as it directly affects the performance of your welding projects.

2. Pricing Compare prices across various suppliers. While cost is a factor, choosing the cheapest option may not always provide the best value if it compromises quality.

3. Delivery Capabilities Reliable shipping and timely delivery can prevent project delays. Suppliers with robust logistics operations can meet urgent needs effectively.

4. Technical Support A supplier offering technical assistance can help troubleshoot issues and provide valuable advice on welding techniques and material compatibility.

5. Customer Reviews Researching feedback from previous customers can provide insight into the supplier’s reliability and quality of service. Make informed decisions based on their experiences.

6. Local vs. Global Suppliers Consider whether to source from local manufacturers or international suppliers. Local suppliers may offer faster delivery times and lower shipping costs, while global suppliers may provide a wider range of products.

Conclusion

Sourcing wholesale 309 stainless steel welding rods from a trustworthy supplier can significantly enhance the efficiency and quality of your welding projects. By carefully evaluating potential suppliers based on product quality, pricing, delivery capabilities, and customer support, you can forge a beneficial partnership that meets your industrial needs. Whether you are in construction, manufacturing, or maintenance sectors, investing time in selecting the right supplier will pay dividends in the quality and durability of your welds.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025