CO2 Welding Wire Manufacturing Factory in China for High-Quality Production

The Rise of China’s CO2 Welding Wire Industry

In recent years, China has emerged as a pivotal player in the global manufacturing landscape, particularly in specialized sectors like welding wires. Among these, CO2 welding wires, also known as gas-shielded welding wires, are gaining substantial traction due to their efficiency and effectiveness in various applications. This article delves into the intricacies of China’s CO2 welding wire factories, their production processes, and the implications for the global market.

CO2 welding, which involves the use of carbon dioxide as a shielding gas, provides several advantages over traditional welding methods. It not only enhances the quality of welds but also significantly improves productivity. The versatility of CO2 welding allows it to be effectively employed in different industries, including automotive, construction, and heavy machinery manufacturing. As a result, the demand for CO2 welding wires has seen an upward trajectory, propelling the growth of specialized factories across China.

The Rise of China’s CO2 Welding Wire Industry

One of the notable aspects of China’s CO2 welding wire manufacturing industry is its focus on research and development. Chinese factories are increasingly investing in R&D to improve wire formulations and enhance the performance characteristics of their products. This is crucial, as the properties of welding wire, including its tensile strength, ductility, and chemical composition, significantly influence the efficacy of welding processes. Factories that prioritize R&D are well-positioned to create innovative products that meet the evolving demands of various industries.

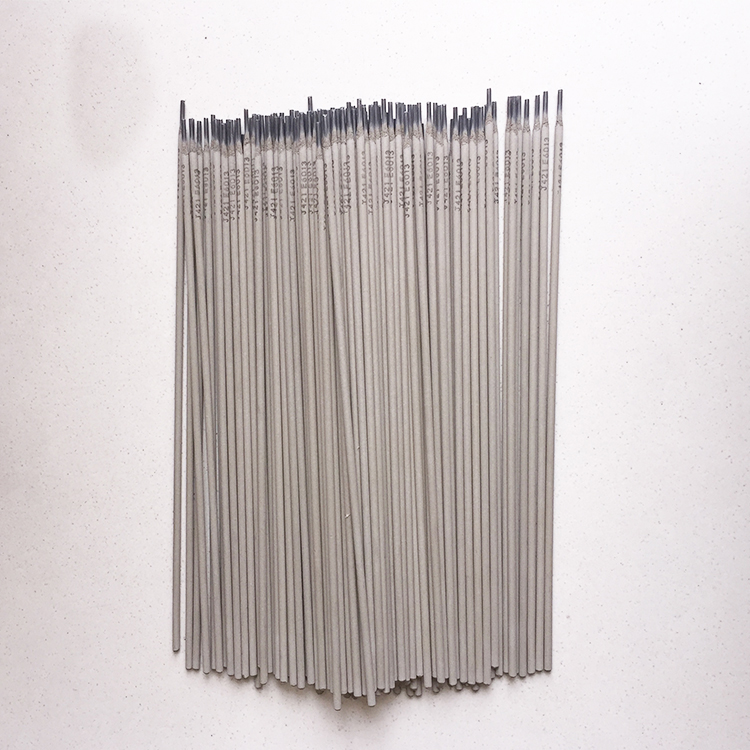

china welding wires co2 factory

Moreover, China's industrial clusters, specifically in regions rich in manufacturing capabilities, foster a competitive environment that accelerates growth. Factories benefit from proximity to suppliers of raw materials, reducing transportation costs and timeframes. This geographical advantage also enhances collaboration between manufacturers and their suppliers, facilitating better quality control and expedited production times.

In terms of export potential, China has become a significant supplier of CO2 welding wires to various international markets. Many countries, particularly those in North America and Europe, seek high-quality welding supplies, and Chinese manufacturers meet this demand through consistent production and competitive pricing. The trade relationships cultivated through these exports not only enhance China’s economic standing but also contribute to global supply chains in the manufacturing sector.

While the growth prospects are promising, the China CO2 welding wire industry is not without its challenges. Increasing environmental regulations are pushing manufacturers to adopt greener practices. This involves investing in cleaner technologies and ensuring that production processes align with sustainable development goals. Moreover, as global competition heats up, Chinese factories must continually innovate to maintain their edge in quality and pricing.

In conclusion, China’s CO2 welding wire factories have carved a niche in the global market, driven by advancements in technology, a commitment to quality, and strong research and development practices. As the demand for efficient and reliable welding solutions continues to grow, these manufacturers are well-positioned to lead the charge, contributing significantly to both local and international industries. With an eye towards sustainability and innovation, the future trajectory of this industry looks bright, reflecting the ongoing evolution of China’s manufacturing prowess in specialized sectors.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025