China Weld Wire Market Trends and Innovations in Welding Technology

The Essential Guide to China Weld Wire Quality, Applications, and Future Trends

Welding is a critical process in various industries, including construction, manufacturing, and automotive. One of the key components that facilitates effective welding is weld wire. In recent years, China has emerged as a significant player in the global weld wire market. This article explores the characteristics, applications, and future trends related to China weld wire.

Understanding Weld Wire

Weld wire, often made from various alloys, is used as a filler material in welding processes. It serves a fundamental purpose in joining metals, providing strength and durability to the welded joint. The quality of weld wire directly affects the efficiency and effectiveness of the welding process. Factors such as chemical composition, tensile strength, and corrosion resistance are crucial in determining the suitability of a weld wire for specific applications.

China’s Role in the Weld Wire Market

China's weld wire production is among the largest in the world, driven by its extensive manufacturing base and increasing demand for welding services. The country's advanced metallurgy and manufacturing technologies have enabled it to produce a wide variety of weld wires, catering to various industries. From mild steel to stainless steel and specialized alloys, China's offerings are diverse and designed to meet the international standards.

One of the reasons for China's success in the weld wire market is its ability to produce high-quality products at competitive prices. This affordability makes Chinese weld wire a preferred choice for many companies globally, especially in developing regions where cost efficiency is a priority.

Applications of China Weld Wire

The applications of weld wire produced in China are vast. In the construction industry, weld wire is critical for reinforcing concrete structures and fabricating steel frameworks. The automotive industry also relies heavily on weld wire for assembling various components, ensuring vehicle durability and safety.

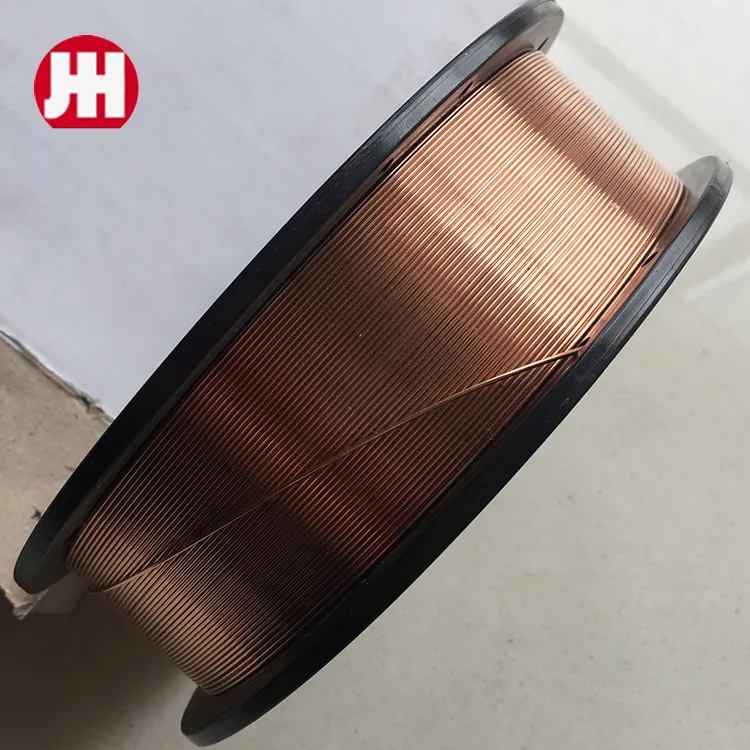

china weld wire

Moreover, the shipbuilding and aerospace sectors utilize specialized weld wires that can withstand extreme conditions. The oil and gas industry, too, employs high-performance weld wires for pipeline construction and maintenance, where reliability is paramount.

The Quality Assurance of Chinese Weld Wire

Quality assurance is a significant concern for buyers of weld wire, and manufacturers in China have increasingly focused on meeting international compliance standards. Many companies adhere to ISO certifications and other quality management systems to ensure consistent product quality. Additionally, stringent quality control measures during production processes help minimize defects and enhance the reliability of weld wire.

Recent years have also seen Chinese manufacturers invest in research and development to innovate and produce advanced weld wire products. This ongoing improvement not only enhances their competitive edge but also contributes to sustainability in welding practices through the development of eco-friendly welding materials.

Future Trends in the Weld Wire Industry

The future of the weld wire market, particularly in China, appears promising. Increasing investments in infrastructure, along with a growing manufacturing sector, are expected to drive demand for high-quality weld wire. Additionally, the global shift toward sustainability is influencing the production of eco-friendly weld wire options, responding to the need for more environmentally responsible manufacturing processes.

Furthermore, technological advancements, such as automation and artificial intelligence, are likely to revolutionize the production processes of weld wire, improving efficiency and reducing costs. Digital platforms and e-commerce are also set to transform how weld wire is marketed and sold, providing easier access to a global customer base.

Conclusion

In conclusion, China’s significance in the global weld wire market cannot be overstated. With its ability to produce quality products at competitive prices, diverse applications across various industries, and a commitment to innovation and sustainability, China's weld wire is poised for continued growth and evolution. As industries across the globe adapt and evolve, the role of weld wire—especially from Chinese manufacturers—will remain pivotal in shaping the future of welding technologies.

-

High Quality Carbon Rods for Welding – Durable & Precise ResultsNewsJul.29,2025

-

High-Performance Cellulose Electrode E6010 for Steel WeldingNewsJul.28,2025

-

High Quality E71T-11 Welding Wire from China – Flux Cored, Easy to UseNewsJul.28,2025

-

High-Quality SG2 Welding Wire for Superior PerformanceNewsJul.27,2025

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025