co2 gas shielded welding wire suppliers

CO2 Gas Shielded Welding Wire Suppliers A Vital Resource for Welding Professionals

In the realm of welding, the equipment and materials used play a crucial role in determining the quality and durability of the final product. One such essential material is CO2 gas shielded welding wire, prominently utilized in various welding processes, especially in MIG (Metal Inert Gas) welding. The market for CO2 gas shielded welding wire is vast, with numerous suppliers offering different types of welding wires tailored to meet diverse industrial needs.

CO2 gas shielded welding, often referred to as MAG (Metal Active Gas) welding when using active gases like carbon dioxide, is popular due to its effectiveness in creating strong welds. The welding wire used in this process is typically made from high-quality steel and is designed to ensure a smooth flow of molten material that helps in forging a robust bond between metals. When selecting a supplier for CO2 gas shielded welding wire, professionals should consider several factors to ensure they are sourcing the best products available.

Firstly, the quality of the welding wire is paramount. Reputable suppliers often conduct rigorous testing to ensure that their wires comply with industry standards. They should provide detailed specifications, including the chemical composition of the wire, its tensile strength, and its performance under various welding conditions. This information allows welders to choose the appropriate wire for their specific projects.

In addition to quality, the variety of welding wires offered by suppliers is crucial. Different applications may require specific types of welding wires, including variations in diameter and coatings. A reliable supplier will have a broad range of options, accommodating everything from general-purpose welding to specialized applications in automotive or structural fabrication.

co2 gas shielded welding wire suppliers

Moreover, customer service and support are critical aspects of a supplier's reliability. Engaging with knowledgeable staff who can offer insights and assistance in selecting the right products is invaluable. Whether it's providing technical support or troubleshooting common welding issues, a good supplier should be a partner in the welding process rather than just a vendor.

Price is another important consideration. While quality should never be compromised, it is essential to compare prices among various suppliers to ensure that you are getting the best value for your investment. Some suppliers may also offer bulk purchasing options or loyalty programs that make it more economical to source materials from them.

Finally, reading customer reviews and testimonials can provide additional insights into a supplier's reputation. Reliable suppliers often have positive feedback from their clients regarding product quality, pricing, and service.

In summary, CO2 gas shielded welding wire suppliers are an integral part of the welding ecosystem. By prioritizing quality, variety, customer service, and competitive pricing, welding professionals can ensure they are well-equipped for their projects. Building a strong relationship with a trusted supplier can lead to improved efficiency and quality in the welding process, ultimately contributing to successful outcomes in various applications.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

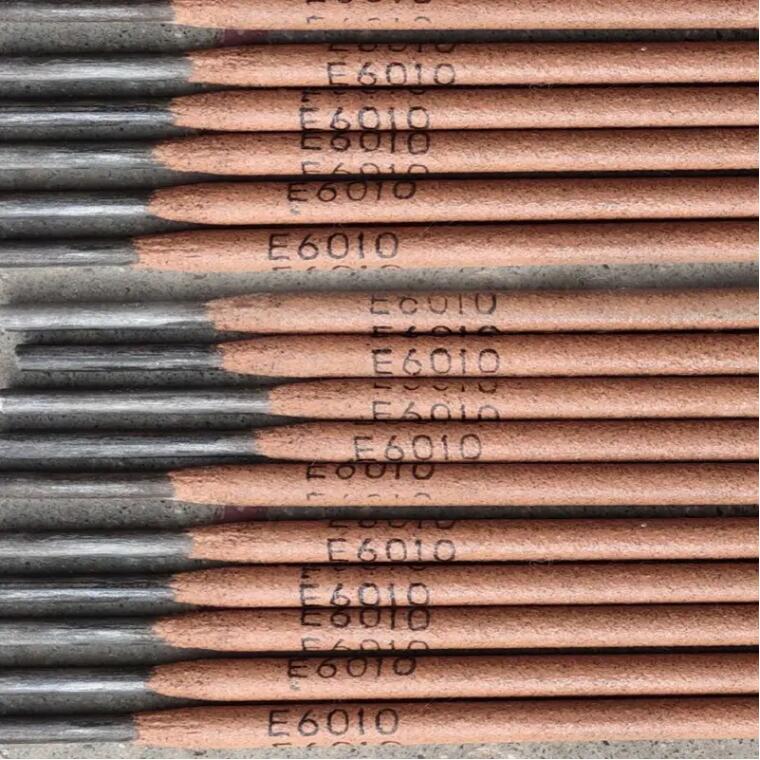

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025