MIG Stainless Steel Wire Production Facility Overview and Manufacturing Processes

Understanding MIG Stainless Steel Wire Manufacturing

MIG (Metal Inert Gas) welding is a widely used welding process due to its efficiency, versatility, and ability to produce strong, high-quality welds. The type of wire used in MIG welding is crucial to the overall performance of the process, especially when it involves stainless steel. In this article, we will explore the intricacies of MIG stainless steel wire manufacturing, its significance, and the factors that contribute to its quality.

The Importance of MIG Stainless Steel Wire

MIG stainless steel wire is designed specifically for welding stainless steel materials, which are known for their corrosion resistance, strength, and durability. Stainless steel is commonly used in various industries, including construction, automotive, food processing, and medical technology. Therefore, the quality of the wire directly impacts the integrity and lifespan of the welded structures.

The wire serves as the filler material that melts during the welding process, creating a strong bond between the base metals. Depending on the application, various types of stainless steel wires, such as ER308L, ER309L, and ER316L, are used. Each type has unique properties that make it suitable for specific applications, taking into account factors like corrosion resistance and weldability.

The Manufacturing Process

The manufacturing of MIG stainless steel wire involves several steps, each playing a vital role in ensuring the final product meets the required standards

.1. Material Selection The process begins with selecting high-quality raw materials. Stainless steel alloys, often composed of iron, chromium, and nickel, are chosen based on the desired characteristics of the finished product.

2. Melting and Refining The selected alloy materials are melted in a furnace. This stage is critical, as impurities must be minimized to achieve optimal performance. Once the metal is melted, refining processes may be employed to remove any remaining impurities and ensure a uniform composition.

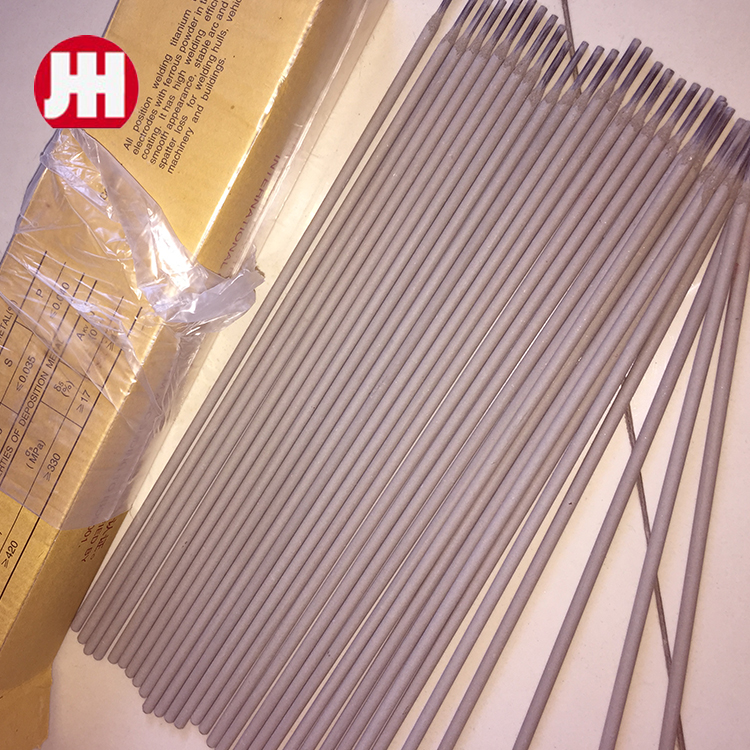

mig stainless steel wire factory

3. Casting After refining, the molten stainless steel is poured into molds to create billets or slabs. This stage is crucial because any defects in casting, such as porosity or inclusions, can lead to weaknesses in the final wire.

4. Rolling and Drawing Once the billets are solidified, they undergo rolling processes to reduce their thickness. This is followed by drawing, where the metal is pulled through a series of dies to produce wire of the desired diameter. The drawing process must be carefully controlled to maintain consistency and prevent defects like cracking or warping.

5. Heat Treatment After drawing, the wire may undergo heat treatment to enhance its mechanical properties. This treatment can improve strength, ductility, and overall performance.

6. Coating Before the wire is packaged, it may be coated to protect against corrosion and improve feedability during the welding process. The coating can also serve to reduce spatter during welding, ensuring cleaner welds.

7. Quality Control Throughout the manufacturing process, rigorous quality control measures are implemented. Testing for tensile strength, elongation, and corrosion resistance is carried out to ensure that the finished wire adheres to industry standards.

Conclusion

MIG stainless steel wire manufacturing is a complex process that requires precision and expertise to produce high-quality products. The importance of selecting the right alloy, refining the materials, and implementing strict quality control cannot be overstated. As industries continue to demand reliable and safe welding solutions, the role of high-quality MIG stainless steel wire will remain essential.

With advancements in technology and manufacturing techniques, the future of MIG stainless steel wire production looks promising. As manufacturers continue to innovate, the capabilities of stainless steel welding will expand, providing even greater opportunities for a wide range of applications across various sectors. Understanding the intricacies of this process not only helps in appreciating the final product but also ensures that welding professionals can make informed choices in their projects.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025