Wholesale Electrodes and Welding Supplies from Trusted Manufacturers for Quality Performance

Understanding Wholesale Soldador Electrodos Factory A Comprehensive Overview

In recent years, the demand for high-quality welding materials has skyrocketed, leading to the emergence of specialized manufacturing units such as wholesale soldador electrodos factories. These factories play a crucial role in providing a diverse range of welding electrodes that cater to various industrial applications. This article delves into the significance of soldador electrodos factories, their operational dynamics, and the impact they have on the welding industry.

What are Soldador Electrodos?

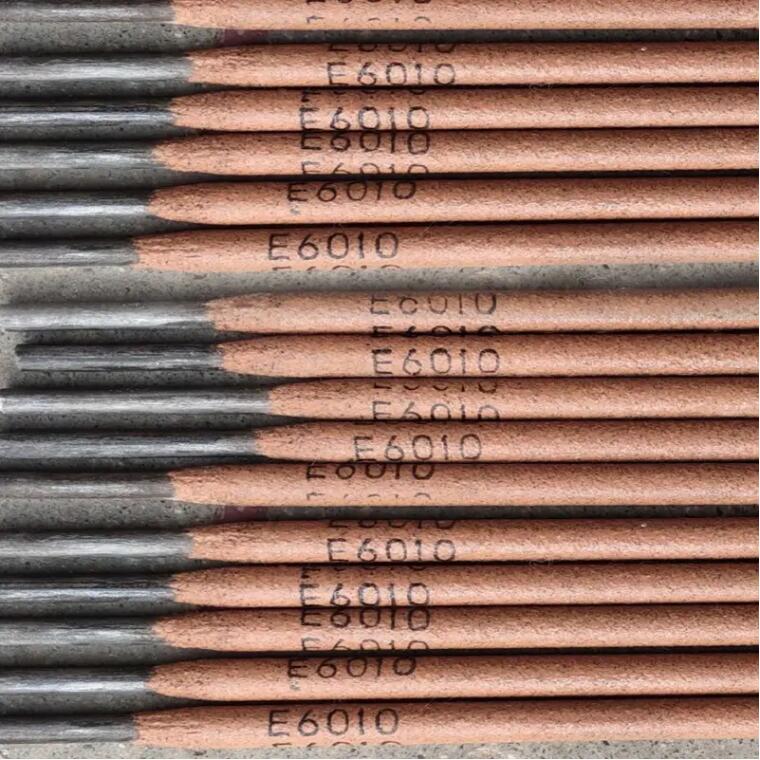

Before diving into the specifics of wholesale factories, it’s important to understand what soldador electrodos are. Welders use electrodes to carry electrical current into the welding arc, melting the workpieces and forming a strong bond. The quality of these electrodes can significantly affect the strength and durability of welds. Soldador electrodos typically come in different types, including coated, solid, and tubular electrodes, each designed for specific applications and materials.

The Role of Wholesale Factories

Wholesale soldador electrodos factories focus on the large-scale production of these essential welding components. These factories are characterized by their ability to produce electrodes in bulk, allowing them to meet the growing demand of both small businesses and large industries. The wholesale model benefits buyers by offering competitive pricing and consistent quality, essential for efficient project execution in various sectors.

Production Process

The production process in a soldador electrodos factory involves several key steps

1. Raw Material Selection The primary materials for producing welding electrodes include steel wire, flux, and coatings. Choosing high-quality raw materials is vital for ensuring the performance of the final product.

2. Manufacturing The manufacturing process involves wire drawing, coating, and precisely forming the electrodes. These steps must be rigorous to ensure uniformity and adherence to industry standards.

wholesale soldador electrodos factory

3. Quality Control Quality assurance is integral to the manufacturing process. Implementing stringent quality control measures helps factories produce electrodes that meet international standards, thereby enhancing their market reputation.

4. Packaging and Distribution Once produced, electrodes are packaged for distribution. Efficient logistics are critical for wholesale factories to deliver products on time to various customers, including distributors, contractors, and retailers.

Significance in Various Industries

Wholesale soldador electrodos factories are vital to numerous industries, including construction, automotive, and shipbuilding. These industries rely heavily on quality welding for structural integrity and safety. Furthermore, as industries evolve and innovate, the demand for specialized electrodes, such as those used in aluminum welding or for high-strength steel, will continue to rise.

As sustainability becomes a focal point for many manufacturing processes, soldador electrodos factories are also exploring eco-friendly materials and methods, contributing to greener welding practices. This shift aligns with global efforts to reduce waste and promote sustainability in industrial operations.

Challenges and Solutions

While wholesale soldador electrodos factories play an essential role in the welding industry, they also face several challenges. Fluctuating raw material prices, stringent regulations, and the need for continuous innovation can impact operational efficiency. To overcome these challenges, factories are investing in research and development to improve electrode formulations and production techniques, thereby enhancing performance while reducing costs and waste.

Conclusion

In conclusion, wholesale soldador electrodos factories are integral to the modern welding landscape. Their ability to provide high-quality welding electrodes at competitive prices ensures that industries can meet their production demands efficiently. As technological advancements continue to shape the welding sector, these factories will play an even more significant role in delivering innovative solutions to an evolving market. Businesses relying on welding must keep an eye on developments within these factories, as they remain pivotal in defining the future of manufacturing and construction standards globally. By investing in quality and sustainability, soldador electrodos factories are not just responding to market demands; they are creating a robust foundation for future welding innovations.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025