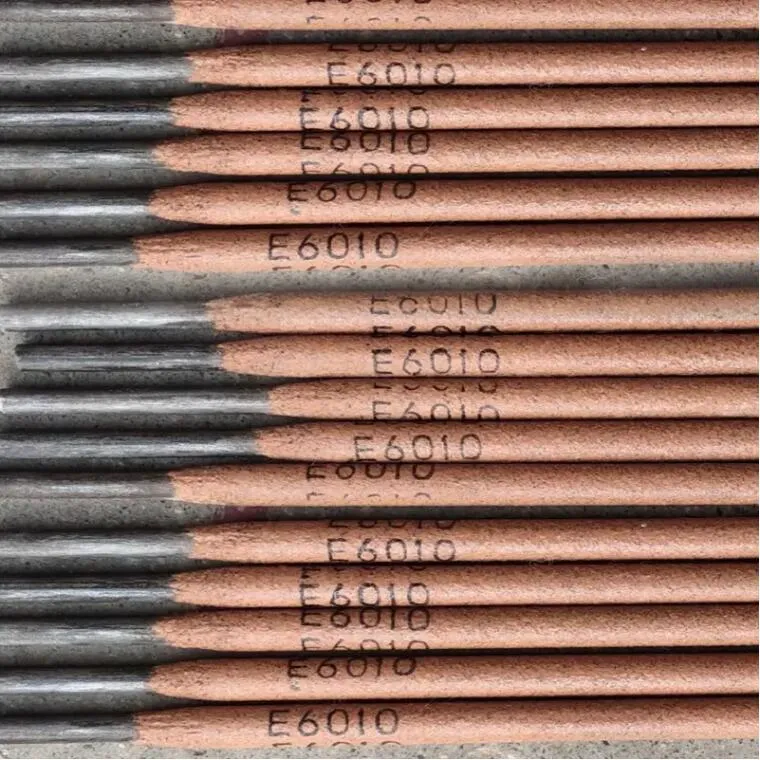

2.5 mm welding electrode

The Importance of 2.5 mm Welding Electrodes in Modern Welding Applications

Welding is a crucial process in various industries, including construction, automotive, manufacturing, and many others. The choice of welding electrode plays a vital role in determining the quality, strength, and overall performance of welded joints. Among the various sizes available, the 2.5 mm welding electrode is a popular and widely used option, particularly in light to medium welding applications.

Versatility and Applications

The 2.5 mm welding electrode is favored for its versatility. It works effectively with a range of materials, including mild steel, stainless steel, and cast iron. Its size makes it suitable for welding thin to medium thickness materials, typically ranging from 1 mm to 5 mm. This makes the 2.5 mm electrode an ideal choice for projects like automotive repairs, household maintenance, and various fabrication tasks.

Given its manageable size, the 2.5 mm electrode provides a good balance between penetration and control. It is easier to maneuver compared to larger electrodes, making it suitable for beginners and experienced welders alike. This electrode size allows for smooth welding arcs and minimizes the risk of burn-through, which is particularly important when working with thinner metals.

Quality of Welds

In terms of weld quality, the 2.5 mm welding electrode delivers excellent results when used correctly. The smaller diameter produces a finer weld bead, which can enhance the aesthetic quality of the finished product. Additionally, the correct selection of electrode type, such as E6013 or E7018, can further improve the mechanical properties of the weld. These electrodes are designed for specific applications, ensuring that welds have optimal tensile strength and impact resistance, meeting industry standards.

2.5 mm welding electrode

Compatibility with Welding Machines

One of the notable advantages of the 2.5 mm electrode is its compatibility with various welding machines. This electrode size can be used with both AC and DC welding machines, providing flexibility for welders. Whether using a transformer-based unit or an inverter welding machine, the 2.5 mm welding electrode can achieve consistent results, making it a preferred choice among professionals.

Tips for Effective Use

To maximize the effectiveness of 2.5 mm welding electrodes, several practices should be observed. Firstly, proper electrode angle and travel speed are crucial. Maintaining a steady angle and consistent speed helps achieve uniform penetration and bead appearance. Secondly, it is essential to clean the surface of the metal before welding to remove any contaminants that could weaken the weld. Finally, selecting the right amperage setting on the welding machine will ensure optimal arc stability and weld quality.

Conclusion

In summary, the 2.5 mm welding electrode is a versatile and essential tool in the welding industry. Its ability to deliver high-quality welds on various material thicknesses makes it indispensable for both professional welders and hobbyists. By understanding the specifications and applications of the 2.5 mm welding electrode, welders can enhance their skills and achieve superior results in their projects. Whether in heavy industry or home-based work, the reliability of this electrode size continues to stand the test of time.

-

2.5mm Stainless Steel Welding Rods High-Strength & Corrosion-ResistantNewsMay.08,2025

-

Premium 2.5mm SS Welding Rods High-Strength Pipe Welding SolutionsNewsMay.08,2025

-

China Welding Steel Rods & Electrodes High-Quality Manufacturers & FactoriesNewsMay.07,2025

-

High-Strength Welding Rod 60 13 China Pipe Welding SupplierNewsMay.07,2025

-

Stainless Steel Gasless MIG Welding Wire Durable, Rust-ResistantNewsMay.07,2025

-

High-Quality Electric Welding Electrodo Wholesale Factory & SuppliersNewsMay.07,2025