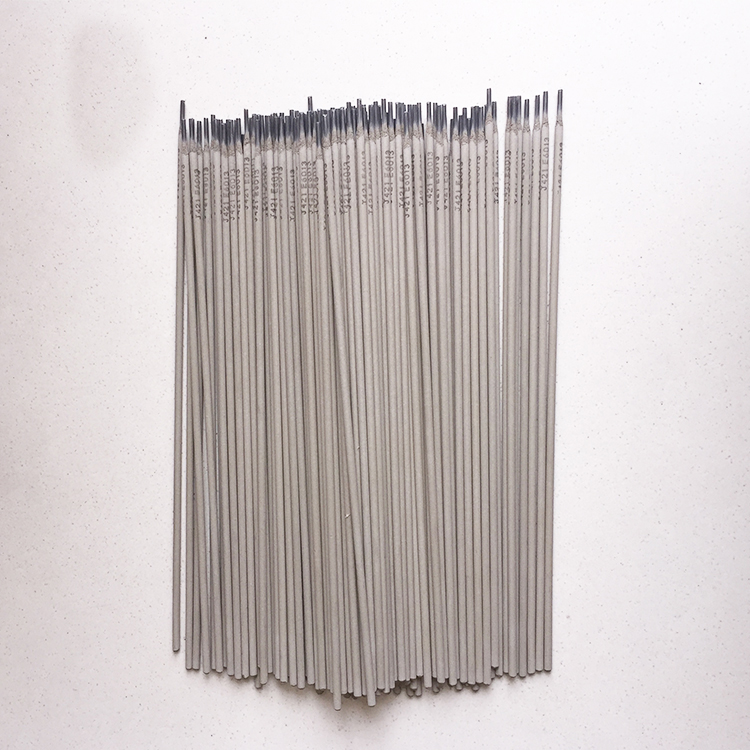

Manufacturers of 2.5mm 6013 Welding Electrodes for Quality Welding Solutions

The Importance of 2.5mm 6013 Welding Electrodes in Modern Industries

Welding is an integral process in various industries, including construction, manufacturing, and repair. Among the diverse array of welding electrodes available in the market, the 2.5mm 6013 welding electrode stands out for its versatility and effectiveness. Understanding the significance of this electrode can help businesses optimize their welding practices and ensure high-quality results.

Understanding 6013 Welding Electrode

The 6013 welding electrode is a type of coated electrode used for arc welding, particularly in the process known as Shielded Metal Arc Welding (SMAW). This electrode features a mild steel core with a rutile-based coating that provides excellent welding characteristics. One of the defining features of the 6013 electrode is its ability to produce a smooth, aesthetically pleasing weld bead with minimal spatter, making it a preferred choice for both professional welders and hobbyists.

With a diameter of 2.5mm, the 6013 electrode is ideal for various applications, including thin materials, automotive repairs, and light fabrication. Its manageable size grants welders enhanced control, which is especially beneficial in overhead and vertical welding positions.

Characteristics of 2.5mm 6013 Welding Electrodes

The 2.5mm 6013 welding electrode possesses several characteristics that contribute to its widespread usage

1. Ease of Use The 6013 electrode is known for its forgiving welding characteristics, making it easier for novice welders to handle. Its stable arc and good penetration into base materials allow even less experienced users to achieve satisfactory results.

2. Versatility This electrode is suitable for welding a range of materials, including mild steel and certain alloys. It can be utilized in various positions—flat, horizontal, vertical, and overhead—making it relevant for multiple applications.

3. Good Arc Stability The rutile coating on the electrode aids in maintaining a stable arc, which is crucial for consistent weld quality. This stability reduces the likelihood of defects, ensuring a reliable weld.

4. Low Spatter and Clean Finish One of the main advantages of using 2.5mm 6013 electrodes is the reduced spatter, which minimizes post-weld cleanup. Additionally, the clean finish of the welded surface is often more aesthetically pleasing, which is essential for applications where appearance matters.

2.5mm welding electrodes 6013 factories

Applications in Various Industries

The versatility of the 2.5mm 6013 welding electrode allows its application across numerous industries

- Construction In the construction industry, these electrodes can be used for structural steelwork, where precision and strong joints are vital.

- Automotive For bodywork and minor repairs, the 6013 electrode is ideal, providing a clean and neat weld that ensures the integrity of the vehicle’s structure.

- Manufacturing In manufacturing, these electrodes can be effectively employed in the creation of products ranging from small brackets to larger machinery components.

- Arts and Craft Hobbyists and artists often utilize 2.5mm 6013 electrodes for metal sculptures and decorative pieces, benefiting from the electrode's ability to produce smooth, visually appealing welds.

Choosing the Right Factory for 2.5mm 6013 Electrodes

When it comes to procuring 2.5mm 6013 welding electrodes, selecting the right manufacturer is essential. Factors such as compliance with industry standards, product quality, and customer service should guide purchasing decisions. Establishments that invest in quality control and provide clear specifications for their electrodes are often the most reliable.

Conclusion

The 2.5mm 6013 welding electrode plays a critical role in modern welding applications. Its ease of use, versatility, and strong performance make it a favorite among professionals and enthusiasts alike. As industries continue to evolve, the demand for high-quality welding electrodes will grow, ensuring that electrodes such as the 6013 remain essential tools in various welding operations. By selecting the right manufacturers and incorporating this electrode into their processes, businesses can enhance productivity and achieve high-quality welds that meet demanding industry standards.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025