High-Quality Manufacturing of 7018 Arc Welding Rods for Reliable Performance

The Importance of 7018 Arc Welding Rods in Modern Welding Applications

Welding is a vital process in various industries, from construction to manufacturing. Among the plethora of welding rods available, 7018 arc welding rods have gained a reputation for their exceptional quality and versatility. These electrodes are crucial for professionals who seek strong, durable welds, particularly when working with high-strength steel and other metals.

Understanding 7018 Arc Welding Rods

7018 arc welding rods are classified according to the American Welding Society (AWS) standards. The first two digits (70) indicate the minimum tensile strength of the weld metal in thousands of pounds per square inch (psi), which in this case is 70,000 psi. The next digit (1) signifies the position in which the electrode can be used, meaning it can be applied in all positions—flat, horizontal, vertical, and overhead. The final digit (8) denotes the type of coating on the electrode, which is low-hydrogen. This coating is essential as it helps to produce welds with lower amounts of hydrogen, minimizing the risk of cracking in the weld.

Key Features of 7018 Welding Rods

1. Low Hydrogen Content The low-hydrogen coating drastically reduces the amount of hydrogen in the weld area. This is paramount when welding high-strength steels, as hydrogen can lead to hydrogen-induced cracking.

2. Excellent Arc Stability 7018 rods provide a smooth and stable arc, which contributes to the ease of use, even for less experienced welders. This consistency is critical in producing high-quality welds without irregularities.

3. Versatility One of the most significant advantages of 7018 welding rods is their versatility. They can be used effectively on a wide range of materials, making them suitable for various applications, including repair work, fabrication, and construction of structures.

4. Strong Welds The resulting welds from 7018 electrodes exhibit excellent strength and ductility. This makes them ideal for projects that require robust joints, such as fabricating bridges, pressure vessels, and other structures that endure significant stress.

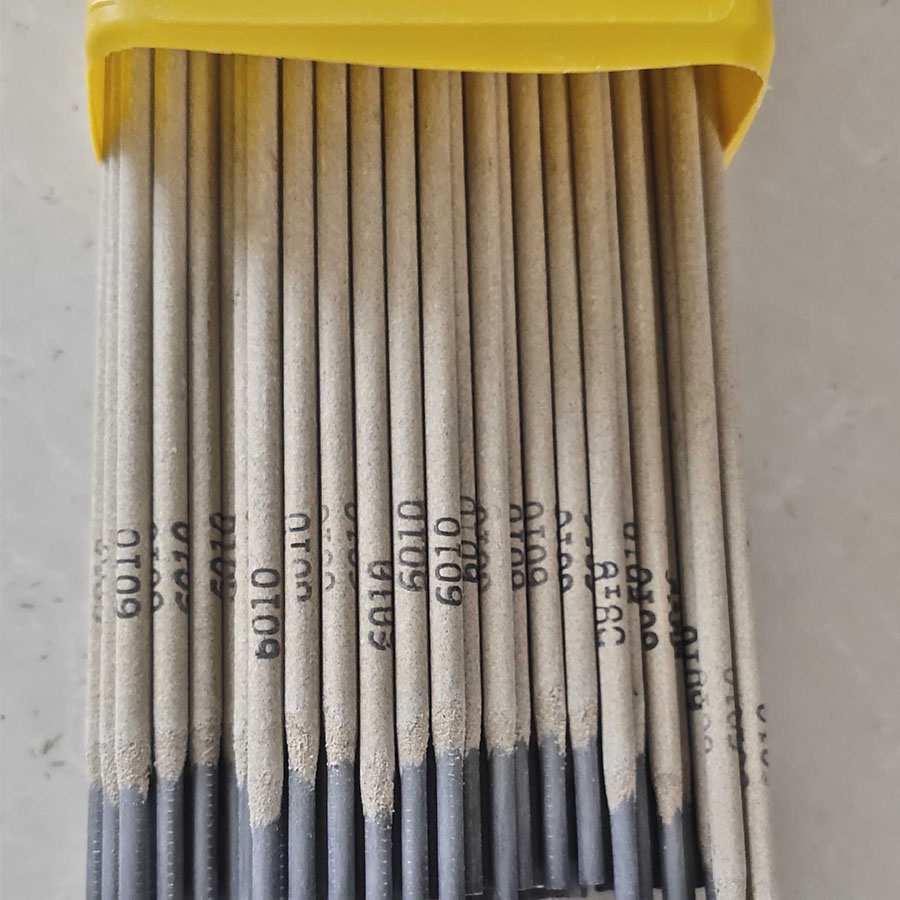

7018 arc welding rod factory

Applications of 7018 Welding Rods

7018 welding rods are widely used across several industries. In the construction sector, they are employed for structural steel welding, where the integrity of the materials is crucial. Moreover, industries that manufacture heavy machinery favor 7018 rods due to their ability to create welds that can withstand high levels of stress and fatigue.

In the automotive industry, 7018 rods are used in fabricating specific components that require high strength and precision. Additionally, in shipbuilding, where weld integrity is critical to ensure safety and performance, 7018 rods are a preferred choice for joining steel plates and structures.

Best Practices for Using 7018 Electrodes

To achieve optimal results when using 7018 rods, adherence to specific best practices is essential. First and foremost, the rods should be stored in a dry environment to prevent moisture absorption, which can compromise the weld’s quality. Preheating the base materials can also enhance the quality of the weld, especially in thicker sections of steel.

Welders should also ensure that the arc length is maintained appropriately; too long an arc can lead to inconsistent welds, while too short can cause sticking and poor penetration. Proper travel speed and technique are crucial in obtaining smooth and uniform bead profiles.

Conclusion

7018 arc welding rods are an indispensable tool in the welding industry, renowned for their strength, versatility, and ease of use. Their low-hydrogen nature, coupled with excellent arc stability, makes them the first choice for many welders tackling demanding projects. Whether in construction, automotive, or manufacturing, the significance of 7018 rods cannot be overstated. As welding technology continues to evolve, these rods will undoubtedly play a crucial role in delivering high-quality, long-lasting welds across various applications. Armed with the right techniques and an understanding of the product, welders can ensure the integrity and durability of their work, meaning 7018 welding rods will remain a staple in welding shops worldwide for years to come.

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025