china co2 welding wire factories

An Overview of CO2 Welding Wire Factories in China

China has established itself as a global leader in the manufacturing of welding materials, including CO2 welding wires, which are crucial in various industrial applications. The country's extensive industrial base, skilled workforce, and advanced technology contribute significantly to its status as a hub for welding wire production.

The Importance of CO2 Welding Wire

CO2 welding wire, often referred to as gas-shielded welding, is vital for various welding processes like MIG (Metal Inert Gas) welding. This type of welding wire is typically made from mild steel and is designed to be used with carbon dioxide gas as a shielding agent. The primary advantage of using CO2 for welding is that it not only provides excellent protection against atmospheric contamination but also produces high-quality welds with minimal spatter. As a result, CO2 welding wires are extensively used in sectors such as automotive, construction, and manufacturing industries.

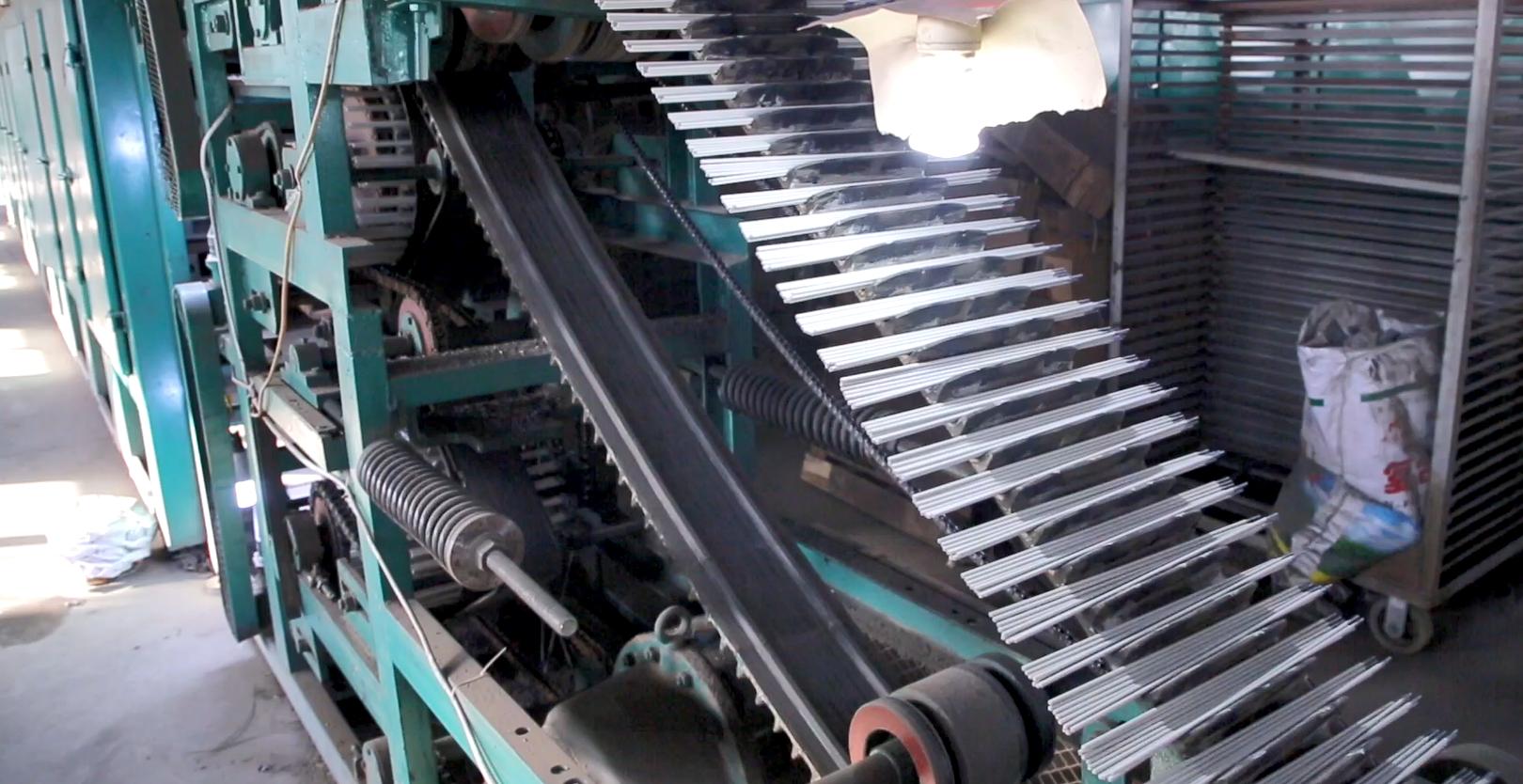

Manufacturing Process

The manufacturing of CO2 welding wires involves several key processes. It begins with the selection of high-quality raw materials, primarily low-carbon steel. The production process includes wire drawing, where the raw material is drawn through dies to achieve the desired diameter. This wire undergoes processes like annealing and coating to enhance its mechanical properties and corrosion resistance. Finally, the wires are spooled and packaged for distribution.

Key Players in the Industry

china co2 welding wire factories

China's market for CO2 welding wire is diverse, with numerous factories spread across different provinces. Major players include companies like Jiangsu TIANSHUN Welding Materials Co., Ltd., Wuhan Ruilong Welding Materials Co., Ltd., and Hebei LANDE Welding Materials Co., Ltd. These companies have established a reputation for quality and reliability, supplying to both domestic and international markets.

Technological Advancements

Chinese welding wire factories are increasingly adopting advanced technologies to enhance production efficiency and product quality. Automation in manufacturing lines, the introduction of quality control systems, and the use of advanced welding techniques have become commonplace. Moreover, machine learning and artificial intelligence are being integrated into production processes to optimize operational efficiency and reduce waste.

Environmental Considerations

As global awareness of environmental issues grows, Chinese CO2 welding wire factories are also focusing on sustainable practices. This includes the implementation of cleaner production techniques and recycling programs for scrap materials. Many factories are committed to reducing their carbon footprint by minimizing energy consumption and utilizing renewable energy sources where possible. Ensuring compliance with national and international environmental regulations is a priority for the industry.

Conclusion

Overall, the CO2 welding wire manufacturing industry in China is robust and continues to evolve. With a strong foundation in technology and innovation, it plays a crucial role in meeting the demand for high-quality welding materials across the globe. As the industry adapts to changing market dynamics and environmental standards, China is poised to maintain its leadership position in the welding wire sector for years to come. Whether for local projects or international exports, the CO2 welding wire factories of China are integral to the global industrial landscape.

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025

-

Best Stainless Steel Flux Core Wire 030 for Welding – High Strength & Clean WeldsNewsJul.06,2025

-

High-Performance Hard Facing Welding Rod – Durable & Wear-Resistant Electrodes for Industrial UseNewsJul.05,2025