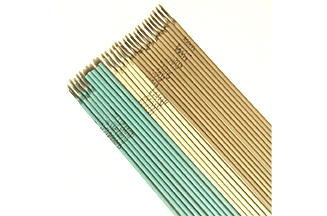

china j422 welding electrodes manufacturer

Exploring the Excellence of China J422 Welding Electrodes Manufacturers

Welding is an essential process in various industries, from construction to manufacturing, and the quality of the materials used significantly impacts the end result. Among the myriad of welding consumables, welding electrodes play a crucial role, with J422 being a prominent type. Known for its versatility and reliable performance, J422 electrodes are widely used in numerous applications. This article delves into the realm of China’s J422 welding electrodes manufacturers, shedding light on their significance, quality standards, and contributions to the global welding industry.

Understanding J422 Welding Electrodes

J422 welding electrodes are classified under the E6013 category, used primarily for mild steel and low-alloy steels. The J in J422 indicates the type of coating, while the 422 refers to the specific composition of the electrode. The E6013 type is characterized by its usability in various positions, including vertical and overhead welding, making it a favored choice among welders. The electrode's arc stability, ease of use, and minimal spatter make it an attractive option for both professional and amateur welders.

Chinese Manufacturers Leading the Charge

China has emerged as a significant player in the global market for welding consumables, including J422 welding electrodes. Several manufacturers in China specialize in producing high-quality welding electrodes that meet international standards. These manufacturers utilize advanced technology and rigorous quality control processes to ensure that their products meet the specific needs of their customers.

One of the primary advantages of Chinese manufacturers is their ability to produce welding electrodes at a competitive price without compromising on quality. This balance makes them an appealing option for businesses looking to reduce costs while maintaining high standards of welding performance. The large-scale production capabilities of Chinese manufacturers also allow them to cater to both domestic and international markets efficiently.

Quality Standards and Certifications

china j422 welding electrodes manufacturer

To ensure the reliability and safety of J422 welding electrodes, manufacturers must adhere to stringent quality standards and certifications. Many Chinese manufacturers comply with international standards such as ISO 9001, ensuring that their production processes meet rigorous quality management criteria. Additionally, some may also have specific certifications for welding consumables, such as those from the American Welding Society (AWS) or European standards.

These certifications not only demonstrate a commitment to quality but also provide assurance to customers regarding the performance and safety of the welding electrodes. Manufacturers often invest in modernizing their production facilities and incorporating quality assurance processes, which further enhances their product reliability.

Innovation and Development in Welding Technology

Aside from providing high-quality products, Chinese manufacturers are also at the forefront of innovation in welding technology. Research and development are critical in this industry as new materials and techniques continuously emerge. Many Chinese manufacturers collaborate with research institutions to develop advanced welding consumables that meet the evolving needs of the market.

Innovations in the formulation of welding electrodes, such as improved coating materials and enhanced arc stability, contribute to better welding characteristics. This not only leads to higher quality welds but also increases productivity by reducing the time and effort required for the welding process.

Conclusion

In conclusion, the landscape of J422 welding electrodes manufacturers in China is marked by a blend of quality, innovation, and competitive pricing. As global demand for effective welding solutions continues to rise, Chinese manufacturers are well-positioned to lead the charge, making significant contributions to the industry. By adhering to strict quality standards, embracing technological advancements, and maintaining affordability, these manufacturers are paving the way for a brighter future in welding. Whether you are a professional welder or a DIY enthusiast, understanding the value of quality electrodes can make a substantial difference in achieving successful welding outcomes.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025