china mig welding electrode factory

The Rise of China’s MIG Welding Electrode Factories

In the realm of industrial manufacturing, one of the most critical components involved in the welding process is the electrode. In recent years, China has emerged as a global powerhouse in the production of Metal Inert Gas (MIG) welding electrodes. This article aims to explore the factors contributing to the growth of China's MIG welding electrode factories, the technology involved, and the impact on both domestic and international markets.

Understanding MIG Welding

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a versatile welding process that has found widespread application across various industries. It employs a continuous feed of a welding wire that serves as an electrode, along with a shielding gas that protects the molten weld pool from contamination. The benefits of MIG welding, including high speed, ease of use, and minimal post-weld cleanup, have made it a preferred method in sectors such as automotive, construction, and manufacturing.

The Growth of Electrode Manufacturing in China

China's emergence as a leading producer of MIG welding electrodes can be attributed to several key factors

1. Robust Manufacturing Infrastructure China boasts a well-developed manufacturing ecosystem, with abundant resources, advanced technology, and a skilled workforce. This infrastructure supports large-scale production capabilities, allowing factories to operate efficiently and meet high demand.

2. Government Support The Chinese government has actively promoted the development of the manufacturing sector through favorable policies, financial incentives, and investment in research and development. These initiatives aim to enhance local production capabilities and reduce reliance on imported products.

3. Competitive Pricing One of the hallmark advantages of Chinese manufacturing is competitive pricing. The lower cost of labor, coupled with economies of scale, allows Chinese factories to offer MIG welding electrodes at prices that are often significantly lower than those of their counterparts in other countries.

china mig welding electrode factory

4. Technological Advancements Over the years, Chinese manufacturers have invested heavily in modernizing their technologies. The integration of automation, robotics, and precise quality control measures has improved production efficiency and product quality, enabling them to compete in the global market.

Quality and Innovation

While lower prices have been a driving factor in the success of Chinese MIG welding electrodes, the emphasis on quality and innovation cannot be overlooked. Many factories prioritize research and development to create electrodes that meet international standards. They continuously strive to improve the chemical composition and manufacturing processes, resulting in superior performance characteristics such as better arc stability, minimal spatter, and enhanced corrosion resistance.

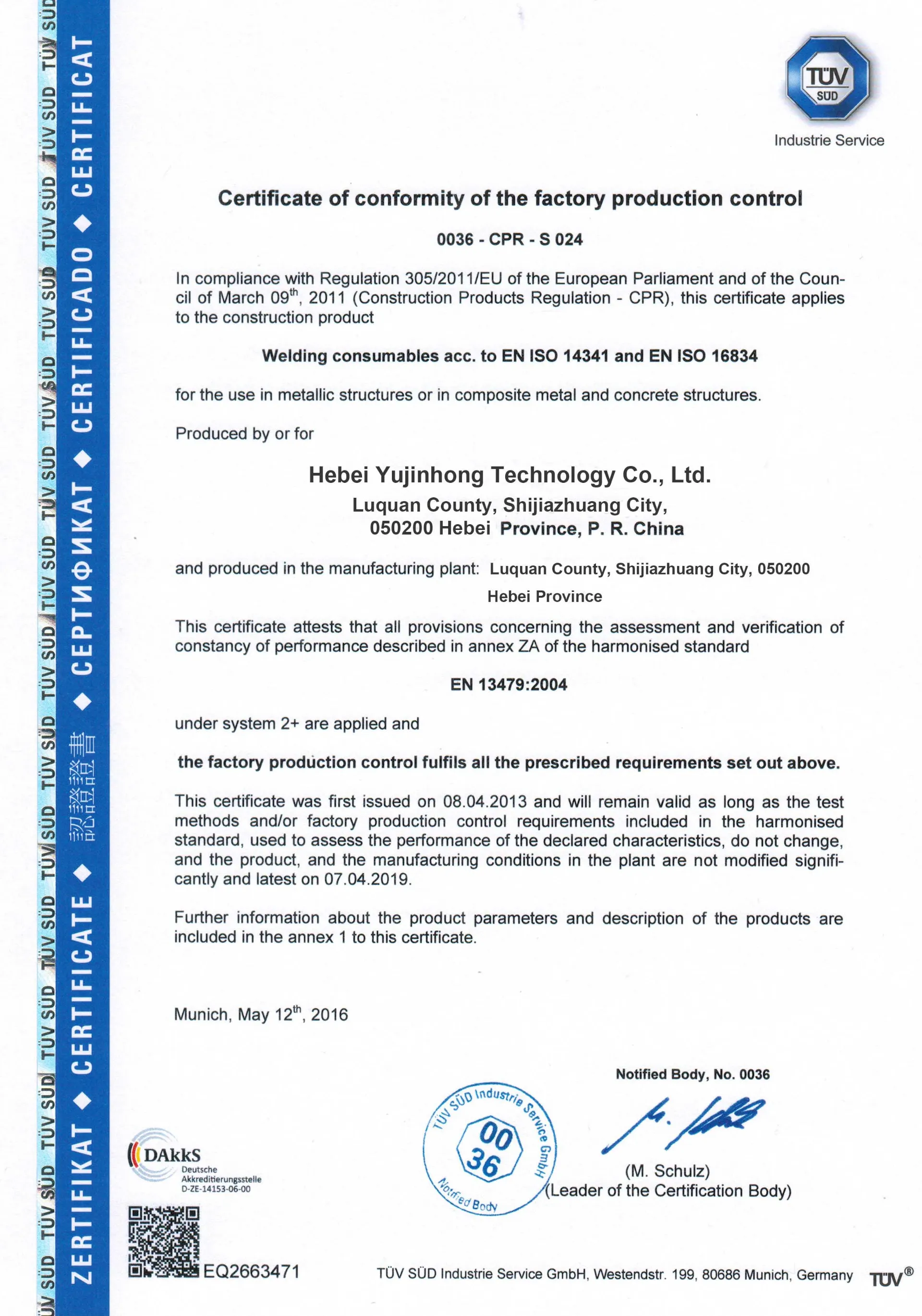

As a testament to their commitment to quality, many Chinese electrode manufacturers have obtained certifications such as ISO 9001, which assures customers of their adherence to strict quality management practices. These certifications play a crucial role in building trust with international clients and expanding export opportunities.

Global Market Impact

The proliferation of Chinese MIG welding electrodes has had significant implications for the global welding market. As Chinese products flood international markets, they have increased competition for local manufacturers in various countries. This has resulted in a dual effect while some firms have struggled to compete on price, others have improved their quality and innovated, thus raising the overall standard of welding materials available globally.

Moreover, as countries recognize the importance of high-quality welding components for their industrial output, many have begun forging partnerships with Chinese manufacturers. This has led to a growing trend of joint ventures and collaborations aimed at harnessing Chinese manufacturing capabilities while ensuring quality through local expertise.

Conclusion

The rise of China as a leading supplier of MIG welding electrodes marks a significant shift in the dynamics of the global manufacturing landscape. Factors such as robust infrastructure, government support, competitive pricing, and relentless innovations have propelled the growth of this sector. As the market continues to evolve, China's welding electrode factories are poised to play a critical role in shaping the future of welding technology worldwide. Companies and industries, both domestically and internationally, must stay abreast of these developments to remain competitive in an increasingly interconnected market. As the demand for high-quality and efficient welding solutions grows, the relevance of Chinese manufacturers is destined to expand, continuing to influence welding practices globally.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025