3.2mm Welding Electrode Supplier from China for High-Quality Welding Solutions

The Role of Chinese Suppliers in the Welding Stick Electrode Market

Welding is an essential process in various industries, from construction to automotive manufacturing. Among the multitude of welding techniques, the use of welding stick electrodes plays a crucial role, particularly in manual arc welding. These electrodes are essential for providing the necessary heat to join materials, and their quality can significantly impact the final outcome of a weld. As industries continue to evolve and demand high-performance welding materials, China has emerged as a leading supplier of welding stick electrodes, particularly the 3.2 mm size.

The Importance of Welding Stick Electrodes

Welding stick electrodes, also known as SMAW (Shielded Metal Arc Welding) electrodes, are composed of a core wire coated with a layer of flux. This flux serves several purposes it protects the molten weld pool from contaminants in the atmosphere, stabilizes the arc, and adds alloying elements to the molten weld. The 3.2 mm diameter is particularly popular due to its versatility, making it suitable for various applications including structural steel fabrication, repair works, and general manufacturing.

Why Choose Chinese Suppliers?

1. Cost-Effectiveness One of the main advantages of sourcing welding stick electrodes from China is cost-effectiveness. Chinese manufacturers have established efficient production processes and economies of scale, which allow them to offer high-quality electrodes at competitive prices. This is particularly beneficial for small to medium-sized enterprises looking to manage their costs while maintaining quality.

2. Quality Control The perception that Chinese products are of lower quality is gradually changing, especially in the welding industry. Many Chinese suppliers have adopted international quality standards, such as ISO certification, to ensure their products meet global quality benchmarks. Furthermore, continuous advancements in metallurgy and welding technology have enabled Chinese manufacturers to offer electrodes that perform on par with international brands.

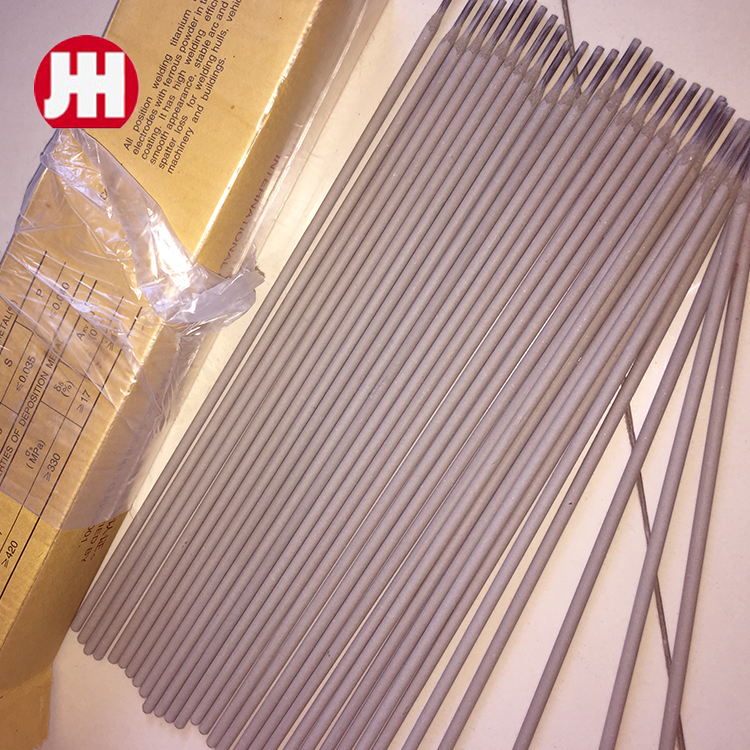

china welding stick electrode 3.2 supplier

3. Diverse Product Range Chinese suppliers often have a broad range of welding electrodes catering to different applications. Whether it’s low-hydrogen, stainless steel, or cast iron electrodes, you are likely to find what you need from a Chinese supplier. This diversity helps industries streamline their sourcing process, reducing the need to engage multiple suppliers.

4. Logistics and Global Reach With the rise of digital commerce and improvements in logistics, Chinese suppliers are well-positioned to serve the global market. Many suppliers offer efficient shipping options and can deliver products to destinations around the world. This global reach ensures that industries far beyond China can access high-quality welding stick electrodes, including the popular 3.2 mm size.

Choosing the Right Supplier

When selecting a welding stick electrode supplier in China, consider the following factors

- Reputation Research the supplier’s reputation in the industry. Look for reviews, testimonials, and case studies that reflect their product quality and customer service. - Certifications Ensure that the supplier holds relevant quality certifications that validate their manufacturing processes and product quality. - Customer Support A reliable supplier should offer excellent customer support, including technical assistance and after-sales service. - Samples Before making a bulk purchase, request samples to assess the quality of the electrodes. This step helps ensure that the product meets your specific requirements.

Conclusion

The demand for quality welding stick electrodes, particularly 3.2 mm size, continues to grow globally. Chinese suppliers play a significant role in this market by offering cost-effective, high-quality products that meet diverse industrial needs. As industries look to optimize their welding processes, sourcing electrodes from reputable Chinese suppliers can lead to improved efficiency, better weld quality, and significant cost savings. As with any procurement decision, due diligence and careful selection of suppliers will ensure that companies can harness the benefits of these essential welding materials while optimizing their operations.

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025