China's Leading Supplier of Welding Stick Electrodes for Quality Welding Solutions

The Role of China in the Welding Stick Electrode Supply Chain

Welding is an indispensable process in various industries, including construction, automotive, shipbuilding, and manufacturing. Among the tools used in this process, welding stick electrodes play a crucial role. These electrodes are essential for arc welding, providing both the filler material and a means to conduct electricity. With the growing demand for welding rods, China has emerged as a leading supplier in the global market, significantly impacting the industry.

Understanding Welding Stick Electrodes

Welding stick electrodes, often referred to as manual metal arc (MMA) electrodes, are composed of a metal core and a coating that protects the welded joint from atmospheric contamination. The choices of materials and coatings vary, depending on the specific welding application, which can range from mild steel to more specialized alloys. The quality of these electrodes is paramount, as they directly influence the strength and durability of the welds.

China's Dominance in the Supply Market

China's welding industry has experienced remarkable growth over the past few decades. With a combination of advanced manufacturing technologies, competitive pricing, and a robust supply chain, Chinese manufacturers have positioned themselves as key players in the global market of welding electrodes. According to various market analyses, China accounts for a significant percentage of the total production and export of welding consumables.

One reason for this dominance is the availability of raw materials at competitive prices. China is rich in natural resources, which aids in the cost-effective production of welding electrodes. Additionally, the country's investment in infrastructure and production facilities ensures that manufacturers can maintain high output levels to meet global demands.

Quality Standards and Certifications

Despite concerns regarding product quality from some suppliers, many Chinese manufacturers have adhered to international quality standards. Certifications such as ISO 9001, AWS (American Welding Society), and EN (European Norm) standards assure international buyers that the products meet high-performance criteria. As a result, many businesses across Europe, Asia, and North America rely on Chinese welding stick electrodes for their various applications.

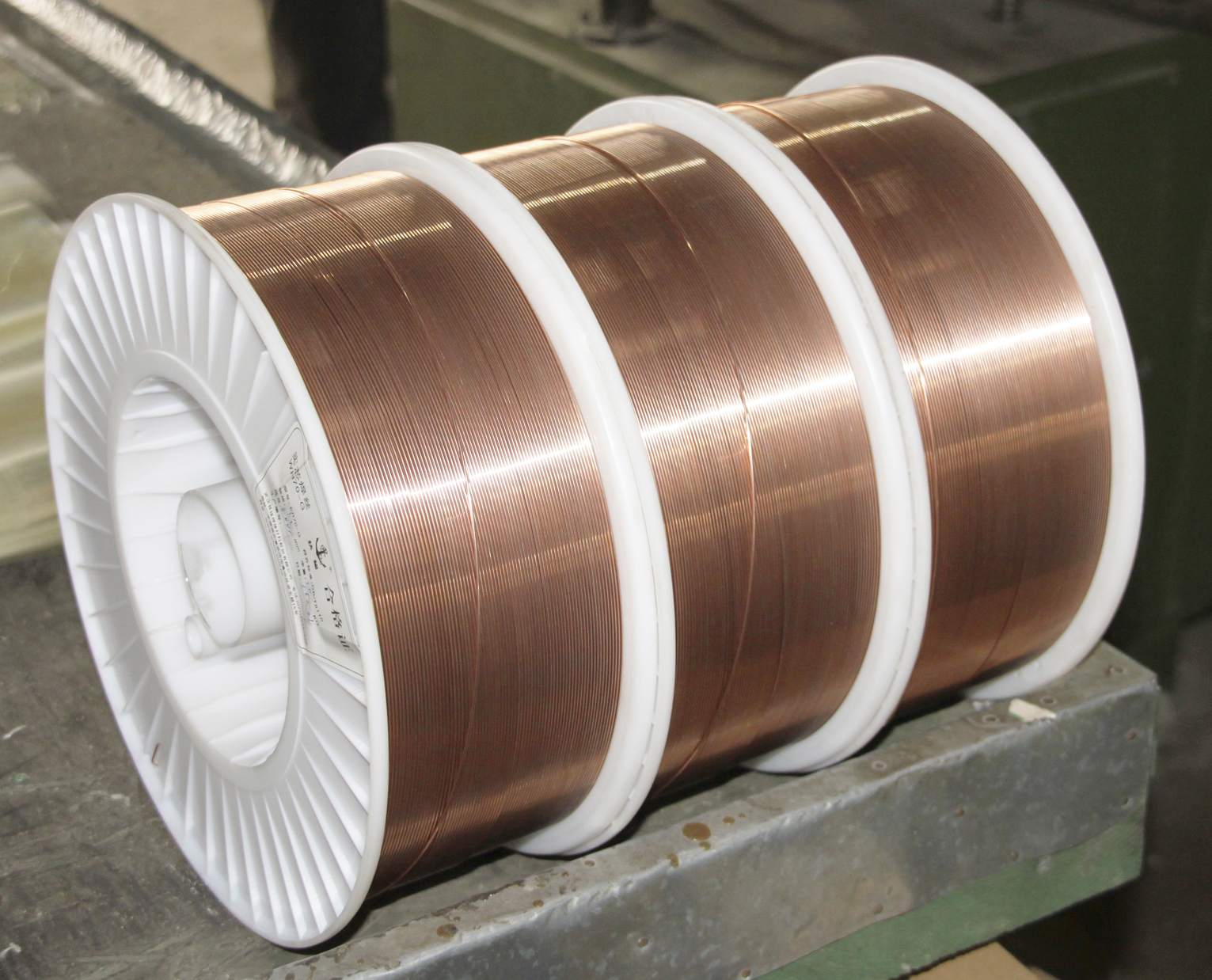

china welding stick electrode supplier

Moreover, continuous innovation and technological advancements play a vital role in maintaining the quality of products. Chinese manufacturers are increasingly investing in research and development to produce advanced welding electrodes designed for specific applications, enhancing performance and user satisfaction.

Challenges Faced by Chinese Suppliers

While China is a dominant player, it faces challenges in the global market. Trade tensions, tariffs, and changing regulations can impact the competitiveness of Chinese products abroad. Furthermore, the emphasis on environmental sustainability has led to stricter regulations concerning manufacturing processes and waste management practices. Chinese manufacturers are adapting to these changes by improving their production methods and investing in greener technologies.

The Future of Welding Stick Electrodes in China

Looking ahead, the trend points towards continued growth for Chinese welding stick electrode suppliers. As industries worldwide become more reliant on automation and robotic welding, the demand for high-quality welding electrodes is expected to rise. Additionally, with the focus on infrastructure development, especially in emerging markets, the consumption of welding electrodes will likely see an upswing.

Chinese suppliers must continue to adapt to market fluctuations and consumer needs, focusing on product innovation, quality assurance, and sustainable practices. Collaborations with international companies can also open up avenues for growth, providing access to new technologies and expertise.

Conclusion

In conclusion, China stands out as a pivotal supplier of welding stick electrodes in the global market. Its robust manufacturing capabilities, adherence to quality standards, and ability to respond to market demands position it well for the future. As the welding industry continues to evolve, Chinese manufacturers will play a crucial role in supplying the necessary materials for modern welding applications, driving both innovation and growth in the sector.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025