Янв . 21, 2025 01:13

Back to list

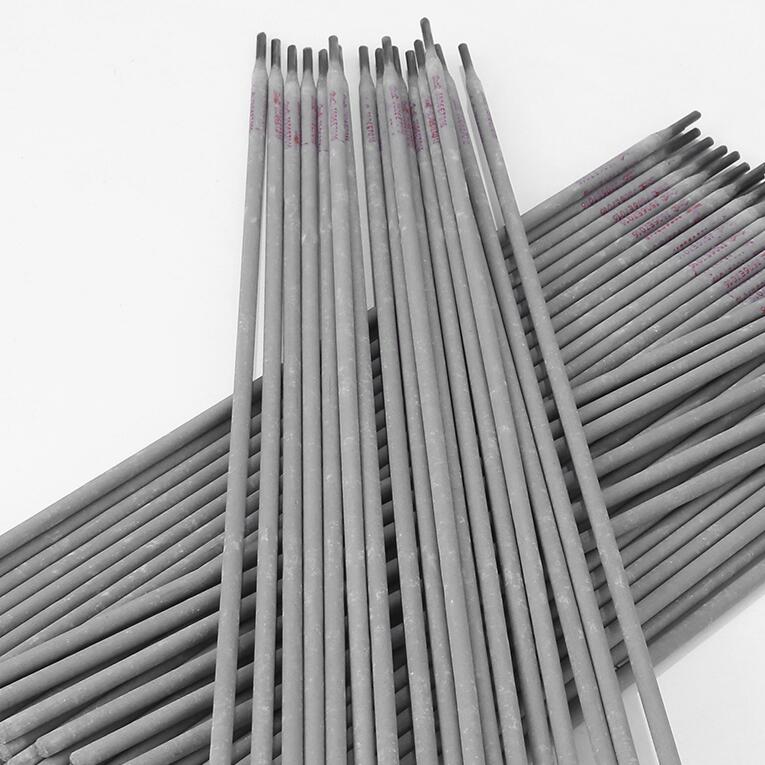

co2 welding wire price

The pricing dynamics of CO2 welding wire have been a subject of interest and scrutiny in the manufacturing and construction industries. Because of its essential role in fostering strong metal joints, the welding wire is a critical component whose market price can significantly impact project budgets and timelines.

Furthermore, the global pivot towards sustainability has begun influencing the industry. Consumers and companies alike are shifting towards environmentally-friendly practices. Consequently, the demand for CO2 welding wires produced through eco-efficient processes is rising. Such sustainable manufacturing techniques might incur higher initial costs but offer a long-term reduction in environmental impact, providing a compelling value proposition. Investing in high-quality CO2 welding wire is not only about maintaining structural integrity but also about leveraging product warranties and customer support services, which are often more robust and reliable when procured from industry leaders. These services ensure operational efficiency and minimize the risk of project delays. In addition, industry forums and trade shows serve as fertile grounds for gathering insights on upcoming trends and pricing forecasts. Networking with peers and attending seminars conducted by welding experts can increase knowledge and assist in making informed purchasing decisions. Overall, while the initial cost of CO2 welding wire can be influenced by myriad external factors, its long-term value cannot be overstated. Enhancements in safety, strength, and sustainability drive the mental shift from viewing this welding wire merely as an expense to recognizing it as a cornerstone investment in durable, reliable, and ethically-sound projects. The key lies in strategic sourcing, adapting to technology advancements, and maintaining an informed perspective on market trends to make cost-effective, quality-ensured procurement decisions.

Furthermore, the global pivot towards sustainability has begun influencing the industry. Consumers and companies alike are shifting towards environmentally-friendly practices. Consequently, the demand for CO2 welding wires produced through eco-efficient processes is rising. Such sustainable manufacturing techniques might incur higher initial costs but offer a long-term reduction in environmental impact, providing a compelling value proposition. Investing in high-quality CO2 welding wire is not only about maintaining structural integrity but also about leveraging product warranties and customer support services, which are often more robust and reliable when procured from industry leaders. These services ensure operational efficiency and minimize the risk of project delays. In addition, industry forums and trade shows serve as fertile grounds for gathering insights on upcoming trends and pricing forecasts. Networking with peers and attending seminars conducted by welding experts can increase knowledge and assist in making informed purchasing decisions. Overall, while the initial cost of CO2 welding wire can be influenced by myriad external factors, its long-term value cannot be overstated. Enhancements in safety, strength, and sustainability drive the mental shift from viewing this welding wire merely as an expense to recognizing it as a cornerstone investment in durable, reliable, and ethically-sound projects. The key lies in strategic sourcing, adapting to technology advancements, and maintaining an informed perspective on market trends to make cost-effective, quality-ensured procurement decisions.

Previous:

Next:

Latest news

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025