electrode weld 2.6 manufacturers

The Evolution of Electrode Weld Manufacturers A Comprehensive Overview

Electrode welding, a fundamental technique in the manufacturing and construction industries, has seen significant advancements over the years. With the rise of innovative technologies and a growing demand for high-quality welds, electrode weld manufacturers have adapted to meet the needs of modern applications. This article explores the evolution of electrode welding, highlighting key manufacturers and their contributions to the industry.

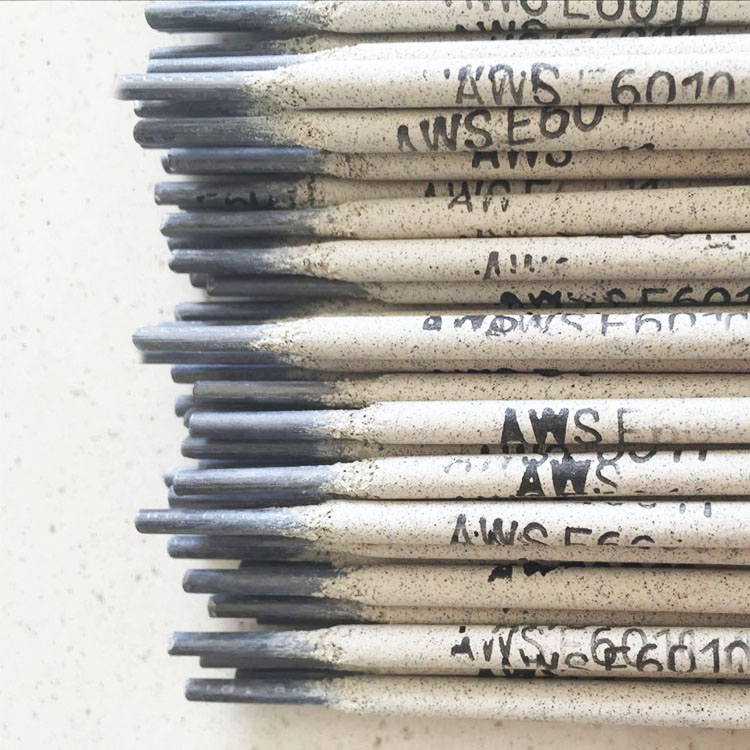

Understanding Electrode Welding

Electrode welding, commonly known as stick welding or Shielded Metal Arc Welding (SMAW), involves using an electrode coated in flux to join materials together. When the electrode is heated, it melts and forms a weld pool, while the flux creates a protective gas shield to prevent contamination. This method is renowned for its versatility, making it suitable for a range of applications from construction to repair work.

The Role of Manufacturers

Manufacturers of electrode welding equipment play a crucial role in ensuring the effectiveness and safety of welding processes. They are responsible for producing quality electrodes that can withstand high temperatures and provide strong corrosion resistance. Several key players dominate the market, each specializing in different aspects of electrode welding.

1. Lincoln Electric Lincoln Electric is a leading manufacturer in the welding industry, known for its innovative products and solutions. Their electrodes are designed to cater to various applications, including structural steel and general fabrication. The company’s commitment to research and development has resulted in advanced welding technologies that improve productivity and weld quality.

2. ESAB With a global presence, ESAB has been a pioneer in the welding industry for over a century. Their comprehensive range of welding consumables includes high-performance electrodes suitable for demanding environments. ESAB’s focus on user-friendly products and safety features has made them a trusted choice for welders worldwide.

electrode weld 2.6 manufacturers

3. Miller Electric Miller Electric has established itself as a prominent player in the welding market, offering a broad spectrum of electrodes designed for both amateur and professional welders. With an emphasis on durability and efficiency, Miller's products are engineered to deliver superior welding performance across various materials.

4. Harris Products Group Harris Products Group specializes in gas welding and cutting technologies, including electrodes. Their dedication to sustainability and environmentally friendly practices sets them apart from competitors. By improving the manufacturing processes and raw materials used, Harris aims to reduce the environmental impact of welding.

Innovations in Electrode Welding

In recent years, electrode weld manufacturers have embraced technological advancements such as automation and artificial intelligence. By integrating these technologies, manufacturers can enhance product quality and consistency while reducing operational costs. Automated welding systems have also made it easier to perform complex welds in challenging environments, providing solutions for industries like aerospace and automotive.

Moreover, the introduction of specialty electrodes designed for specific applications—such as high-temperature and high-strength materials—has allowed for greater precision and reliability in welding. This trend is crucial as industries continue to evolve and demand is placed on manufacturers to deliver solutions that meet stringent quality standards.

Conclusion

The landscape of electrode welding manufacturers is continuously evolving. As industries require more advanced welding solutions, manufacturers are responding with innovative products and technologies. Companies like Lincoln Electric, ESAB, Miller Electric, and Harris Products Group are at the forefront of this evolution, driving advancements that enhance productivity and weld quality. As we look to the future, the collaboration between manufacturers and users will be essential in shaping the next generation of electrode welding technologies, ensuring that this vital process continues to meet the demands of a rapidly changing world.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025