Electrodes 6011 1/8 Inch Specifications and Manufacturing Insights for Optimal Performance

Understanding Electrodos A Deep Dive into 6011 1/8” Factory Electrode

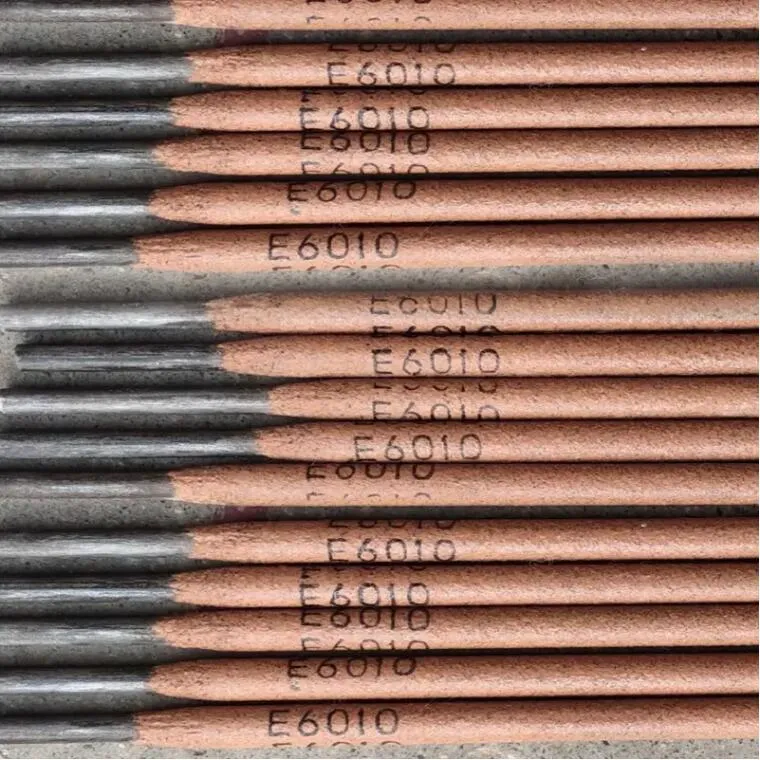

Electrodos, a term derived from the Latin word for electrode, represents a crucial component in various industrial applications, particularly in welding. Among its various types, the 6011 1/8” electrode stands out due to its unique properties and versatility. This article will explore the characteristics, applications, and manufacturing processes involved in making the 6011 electrode, leading us to appreciate its significance in the welding industry.

The 6011 electrode is classified as a mild steel electrode, primarily used in stick welding (SMAW - Shielded Metal Arc Welding). Its designation is based on the American Welding Society (AWS) classification system the “60” indicates a minimum tensile strength of 60,000 psi, “1” refers to the welding position versatility, and “11” implies the type of coating used, which provides excellent arc stability and penetration capabilities. The 1/8” refers to the diameter of the electrode, making it suitable for a range of welding applications.

Understanding Electrodos A Deep Dive into 6011 1/8” Factory Electrode

When it comes to applications, the 6011 electrode is frequently used in farming equipment, maintenance, repair work, and light fabrication. Its ability to produce high-quality welds in various positions means it's commonly found in the agricultural sector, where welding tasks are often performed outdoors and under less than ideal conditions. Moreover, its low cost and availability make it a preferred choice for many welders.

electrodos 6011 1/8 factory

Manufacturing Process

The production of 6011 electrodes involves several critical steps to ensure quality and consistency. The first stage includes the selection of high-quality steel, which serves as the core material for the electrode. The steel is then coated with a mixture of minerals and materials that contribute to the electrodes' specific properties. This coating includes cellulose and iron powder that help in stabilizing the arc and improving bead appearance during welding.

Once the materials are prepared, the electrodes are extruded into the desired diameter, in this case, 1/8. After extrusion, the electrodes undergo a drying process to enhance their performance during welding. The final step includes packaging, ensuring that the electrodes are ready for distribution.

Conclusion

In summary, the 6011 1/8” electrode has cemented its place within the welding industry due to its formidable strengths and versatility. Its ability to perform under various conditions, coupled with its cost-effectiveness, makes it an indispensable tool for welders. Whether in a farm workshop, a metal fabrication shop, or a construction site, the 6011 electrode stands as a symbol of efficiency and durability in welding applications. As industries continue to evolve, the demand for reliable and versatile welding electrodes like the 6011 will only grow, making it a topic worth exploring for anyone interested in welding technology.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025