Factories Producing Welding Rods and Electrodes for Industrial Applications

Understanding Welding Rod Electrodes Factories

Welding is an essential process in various industries, including construction, manufacturing, and automotive. At the heart of welding technology are welding rods and electrodes, crucial components that facilitate the joining of metals. This article explores welding rod electrodes factories, their significance, processes, and future prospects in the welding industry.

The Importance of Welding Rod Electrodes

Welding rods and electrodes serve as consumables in different welding processes. They not only provide the filler material required to create a strong joint but also contribute to the shielding of the weld pool from contaminants in the environment. Different types of electrodes are designed for various applications, including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), and gas metal arc welding (GMAW). The variety allows welders to select the appropriate type based on material, joint configuration, and desired properties of the finished weld.

The Manufacturing Process

The production of welding rod electrodes involves several stages. The process usually begins with the selection of raw materials, which typically include steel, flux, and alloying elements. Steel is the primary component that provides strength and ductility. Flux materials are used to promote desirable welding characteristics, such as stability and protection against atmospheric contamination.

1. Raw Material Preparation The first step involves sourcing high-quality raw materials that meet industry standards. The purification and alloying of these materials are crucial to ensure the performance of the final product.

2. Forming The chosen raw materials undergo forming, where they are shaped into wires or rods. This process may include drawing, rolling, and cutting to achieve the desired diameter and length.

3. Coating For many types of electrodes, a coating is applied. This is particularly important for stick welding electrodes. The coating serves multiple purposes it protects the weld metal from oxidation during the welding process and helps stabilize the arc.

4. Quality Control Throughout the manufacturing process, quality control measures are implemented to ensure that the products meet industry specifications. Tests may include tensile strength tests, metallurgical examinations, and performance assessments.

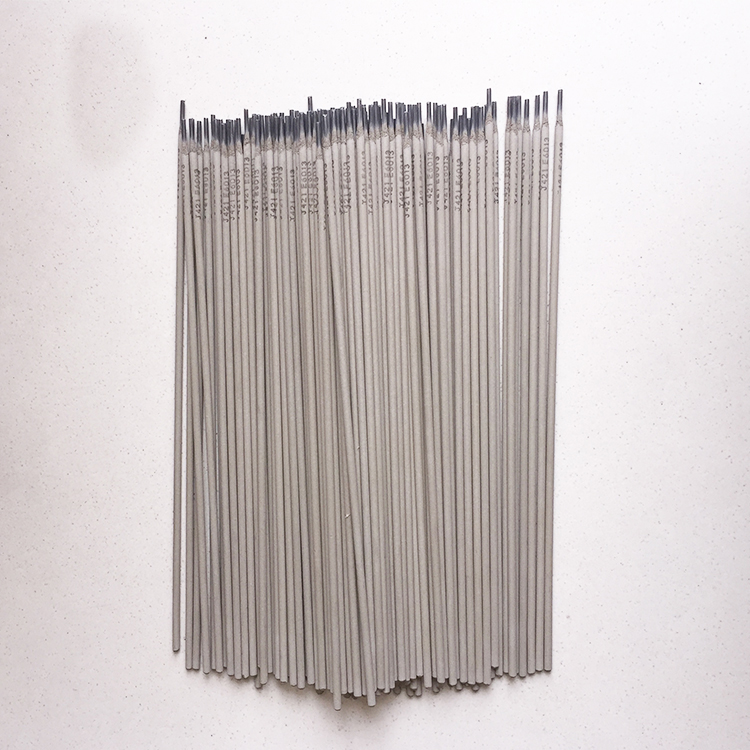

welding rod electrodes factories

5. Packaging and Distribution After passing quality checks, the welding rods or electrodes are packaged appropriately to prevent damage during transport. They are then distributed to warehouses, distributors, and end-users.

The Role of Technology

Welding rod electrodes factories are increasingly adopting advanced technologies to improve production efficiency and product quality. Automation in manufacturing processes minimizes human error and reduces production time. Robotics can handle repetitive tasks, while computer-controlled machines ensure precision in forming and coating.

Additionally, the integration of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), enables factories to monitor production in real time. This not only improves quality control but also optimizes supply chain management, reducing waste and ensuring timely delivery of products.

Future Trends

Looking ahead, the welding rod electrodes industry faces both challenges and opportunities. As industries shift towards more sustainable practices, manufacturers are experimenting with eco-friendly materials and processes. There is also a growing demand for specialized electrodes that can perform well in extreme conditions, such as high heat or corrosive environments.

Moreover, the increasing use of automated welding technologies is driving the need for high-performance electrodes compatible with these systems. Factories that can innovate and adapt to these trends are likely to thrive in the evolving market landscape.

Conclusion

Welding rod electrodes factories play a vital role in the welding industry, providing essential products that support various applications. As technology advances and sustainability becomes more critical, these factories will continue to evolve, ensuring they meet the changing demands of the market. The future of welding rod electrodes will undoubtedly focus on efficiency, quality, and environmental responsibility, paving the way for innovations in welding technology.

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025