soldador electrodos suppliers

The Importance of Choosing the Right Electrode Suppliers in Welding

In the world of welding, the quality of the materials used can significantly influence the strength and durability of the final product. Among these materials, welding electrodes play a crucial role in determining the effectiveness and efficiency of the welding process. Therefore, it’s vital for professionals and companies to choose reliable suppliers when sourcing welding electrodes. This article delves into the factors to consider when selecting electrode suppliers, the types of electrodes available, and the impact of quality suppliers on the welding industry.

Understanding Welding Electrodes

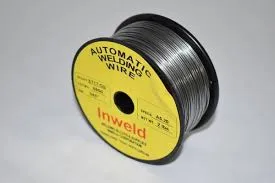

Welding electrodes can be categorized into several types, including shielded metal arc welding (SMAW) electrodes, gas tungsten arc welding (GTAW) electrodes, and gas metal arc welding (GMAW) wires. Each type has its own specific application, compatibility with materials, and welding procedures. The selection of the right electrode is essential as it affects the welding arc stability, penetration, and overall quality of the weld.

SMAW electrodes, for instance, are primarily used for manual welding applications and are known for their versatility and ease of use. GTAW electrodes, on the other hand, are used in applications requiring high purity and precision, such as in aerospace and automotive industries. GMAW wires are favored for their speed and efficiency in production environments.

Why Choose Quality Suppliers?

The supplier of welding electrodes plays a pivotal role in the overall supply chain of welding operations. Here are some key reasons why selecting quality electrode suppliers is essential

1. Material Quality Quality suppliers provide electrodes made from excellent raw materials, which are crucial for achieving optimal weld performance. Poor-quality electrodes can lead to weak welds, increased defect rates, and ultimately, costly repairs or rework.

2. Compliance and Standards Not all electrode suppliers adhere to the same regulatory standards. Reliable suppliers comply with industry and international standards, ensuring that their products meet safety and performance requirements. This compliance is essential, especially in critical applications where integrity is non-negotiable.

3. Technical Support and Expertise Reputable suppliers often provide technical support and expertise to their clients. This support can be invaluable in selecting the right electrode for specific applications, troubleshooting issues during the welding process, and improving overall welding techniques.

4. Consistent Supply The availability of electrodes can be a concern in manufacturing scenarios. Quality suppliers maintain consistent stock levels and have established networks for distribution, minimizing the risk of production downtime due to material shortages.

soldador electrodos suppliers

5. Cost Efficiency While it may be tempting to opt for the cheapest supplier, this decision can lead to higher costs in the long run due to inferior products. Quality electrodes lead to fewer defects, reduced wastage, and improved weld quality, which can save money over time.

How to Identify Reliable Suppliers

When searching for electrode suppliers, consider the following factors

- Industry Reputation Research the company’s history and reputation within the industry. Reviews, customer testimonials, and case studies can provide insight into their reliability.

- Product Range A good supplier will offer a comprehensive range of electrodes to cater to varying welding requirements. This range ensures that you can find the specific products you need without switching suppliers frequently.

- Customer Service Evaluate the supplier's customer service. Are they responsive and helpful? A supplier that prioritizes customer satisfaction can often provide better support when you need it most.

- Certifications Ensure the suppliers possess relevant certifications that demonstrate their adherence to industry standards and quality assurance.

- Locally Available Options Local suppliers can often provide quicker delivery times and reduced shipping costs, making them an appealing option for businesses that require a steady supply of electrodes.

Conclusion

The decision to partner with the right electrode suppliers is a fundamental aspect of successful welding operations. By ensuring quality materials, adhering to industry standards, and providing valuable customer service, reliable suppliers can significantly enhance the welding process. As the industry continues to evolve, the importance of forging strong relationships with quality electrode suppliers will become even more pronounced, driving innovation and excellence in welding applications. Investing time in selecting the right suppliers today can yield substantial benefits in the future, ultimately leading to stronger welds and better overall outcomes in projects.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025