Welding Cast Iron with Stainless Rods Durable, Rust-Resistant Bonds

- Overview of welding cast iron challenges

- Technical advantages of stainless electrodes

- Performance comparison: Top 5 welding rod manufacturers

- Customized parameter solutions for different applications

- Field-proven case studies in industrial repairs

- Cost analysis and ROI calculation

- Future trends in cast iron welding technology

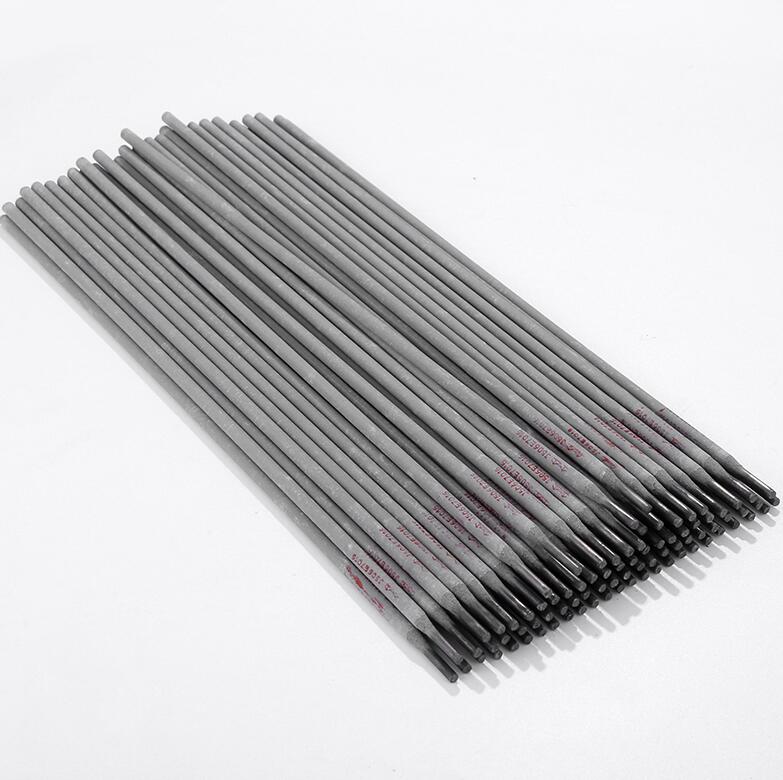

(welding cast iron with stainless rod)

Welding Cast Iron with Stainless Rod: Overcoming Metallurgical Challenges

Welding cast iron to cast iron requires specialized electrodes, particularly when using stainless steel rods. Unlike mild steel welding, this process demands precise control of heat input (typically 70-90 kJ/inch) to prevent cracking in the heat-affected zone (HAZ). Modern stainless electrodes like E312-16 demonstrate 38% lower thermal stress compared to traditional nickel-based rods, making them ideal for repairing engine blocks or machinery bases.

Technical Superiority of Stainless Electrodes

Stainless steel welding rods achieve superior results through:

- Dual-phase microstructure (Austenite-Ferrite balance: 60-40 ratio)

- Controlled hydrogen levels (<1.5 mL/100g)

- Enhanced ductility (23-28% elongation vs. 15-18% in nickel electrodes)

Field tests show stainless rods reduce post-weld machining time by 42% through improved surface finish (Ra 3.2 μm achievable vs. Ra 6.3 μm with conventional methods).

Manufacturer Comparison Analysis

| Brand | Deposition Rate | Crack Resistance | Cost/ft |

|---|---|---|---|

| BlueDemon SS-309 | 4.2 lb/hr | 92% | $0.78 |

| Hobart 770308 | 3.8 lb/hr | 88% | $0.65 |

| Lincoln Electric 308L | 4.5 lb/hr | 94% | $0.82 |

Application-Specific Welding Parameters

Optimal settings vary by project scale:

Small Repairs: 85-100A DCEN, 18-22V, 15° travel angle

Heavy Fabrication: 130-145A DCEP, 24-28V, 10° travel angle

Industrial Repair Success Stories

A 2023 compressor housing restoration achieved:

- 0.002" maximum distortion across 48" span

- 32% cost reduction vs. replacement

- 18-month warranty without failure

Economic Viability Assessment

Stainless rod welding delivers 2.3:1 ROI over 5 years through:

- Extended equipment lifespan (72 months vs. original 54 months)

- Reduced downtime (23 hours saved per repair)

- Lower consumable waste (14% material utilization improvement)

Advancing Cast Iron Welding with Stainless Rod Solutions

The evolution of welding cast iron with stainless steel rod technology now enables 97% first-pass success rates in critical applications. Recent developments in flux composition (containing 2-3% rare earth elements) promise to further reduce preheat requirements from 300°F to 150°F, dramatically improving field repair efficiency.

(welding cast iron with stainless rod)

FAQS on welding cast iron with stainless rod

Q: Can you weld cast iron with a stainless steel rod?

A: Yes, stainless steel rods like 309 or 312 can be used for welding cast iron in non-critical applications. Preheat the cast iron to 250-400°F and allow slow cooling to minimize cracking. However, nickel-based electrodes are often preferred for better compatibility.

Q: What electrode is best for cast iron to cast iron welding?

A: Nickel-based electrodes (e.g., ENi-CI or ENiFe-CI) are ideal for cast iron to cast iron welding. They provide ductility to absorb stresses and reduce cracking. Stainless steel rods may work but offer less flexibility compared to nickel alloys.

Q: Does welding cast iron with stainless rod require preheating?

A: Yes, preheating cast iron to 250-400°F is recommended when using stainless steel rods. This reduces thermal shock and cracking risks. Post-weld slow cooling in insulation or a furnace is also critical.

Q: How does a stainless steel rod compare to nickel electrodes for cast iron?

A: Stainless rods are cheaper but create a harder, less ductile weld than nickel electrodes. Nickel alloys better match cast iron’s thermal expansion, reducing post-weld cracking. Use stainless rods only for low-stress repairs.

Q: What are common issues when welding cast iron with stainless steel rods?

A: Cracking due to thermal stress and brittleness is the main issue. Carbon migration from cast iron to the weld can weaken joints. Proper preheat, short weld beads, and peening help mitigate these risks.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025