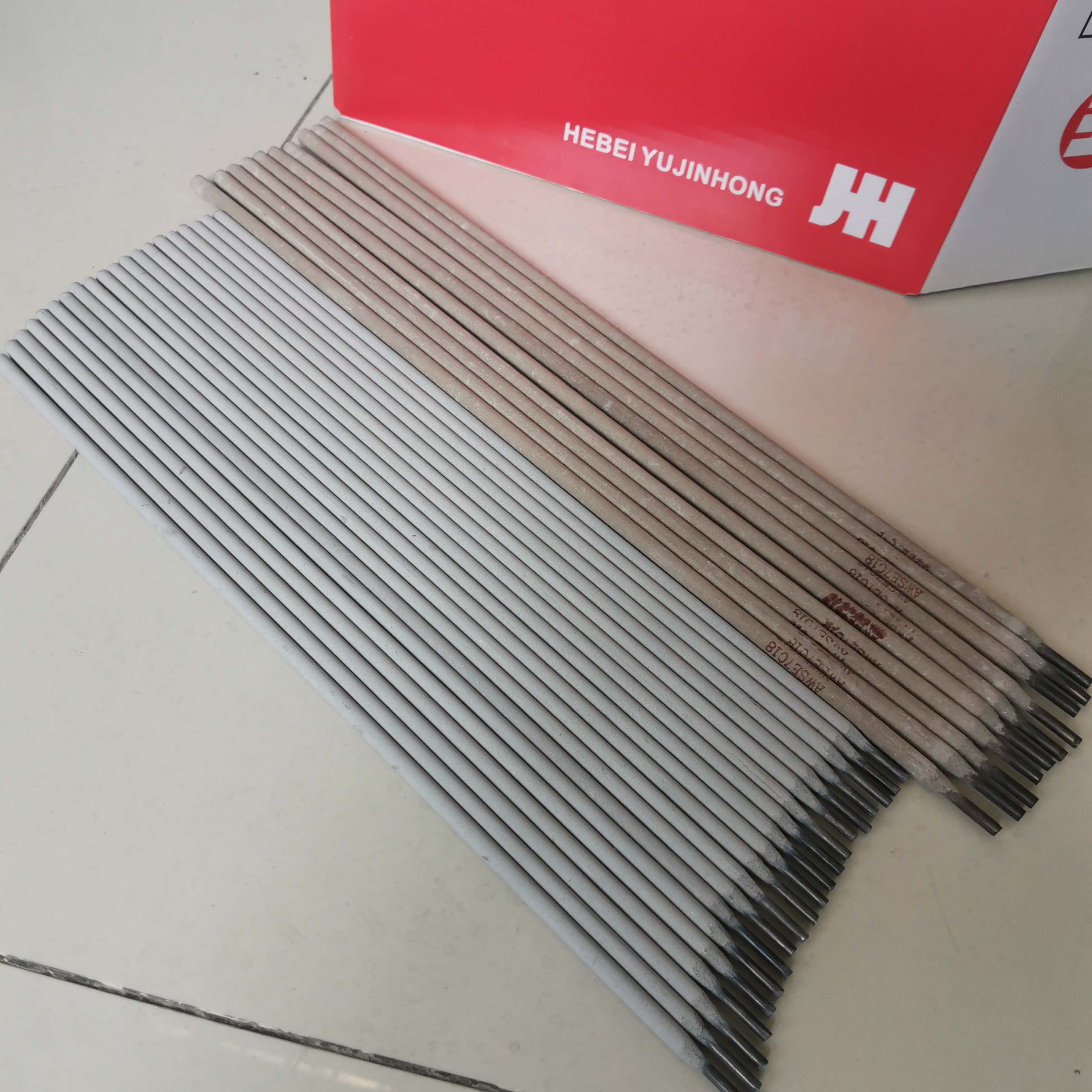

welding rod 7016 for pipes welding

The Significance of Welding Rod 7016 in Pipe Welding

In the world of metal fabrication, the choice of welding rod plays a crucial role in determining the effectiveness of the welding process, particularly when it comes to welding pipes. Among the various types of welding rods available, the E7016 welding rod has gained recognition for its superb performance and versatility.

Characteristics of E7016 Welding Rod

The E7016 welding rod is an all-position, low-hydrogen electrode commonly used for welding carbon steels and low-alloy steels. The ‘E’ in its classification denotes an electrode, while '70' indicates that it has a minimum tensile strength of 70,000 psi. The '16' refers to its chemical composition, which includes a low hydrogen content. This low hydrogen feature is particularly beneficial because it minimizes the risk of hydrogen-induced cracking, which is critical when welding thin pipes or those subjected to harsh environmental conditions.

Applications in Pipe Welding

When it comes to welding pipes, especially those used in construction, oil, and gas industries, the structural integrity of the weld is paramount. Pipes often have to endure intense pressure, thermal expansion, and exposure to various substances. The E7016 rod, with its strong weld beads and excellent arc stability, is especially suitable for these applications. It not only provides high tensile strength but also ensures a clean finish with minimal slag. This characteristic allows for easier inspection of the weld seams, which is essential in industries where safety and quality are non-negotiable.

welding rod 7016 for pipes welding

Welding Techniques and Considerations

Welding pipe with the E7016 rod typically requires expertise in either the Shielded Metal Arc Welding (SMAW) or the Gas Tungsten Arc Welding (GTAW) processes. welders must be familiar with the correct settings for amperage and travel speed to ensure optimal penetration and adhesion. Additionally, preheating the base material can further improve the quality of the weld by reducing the risk of cracking.

One should also consider the environment in which the welding takes place. Windy or damp conditions may affect the stability of the arc; therefore, welders might need to adapt their techniques accordingly. Proper storage of the rods is crucial as well since exposure to moisture can compound any risks associated with hydrogen embrittlement.

Conclusion

In summary, the E7016 welding rod stands out as a premier choice for pipe welding applications due to its strength, versatility, and low-hydrogen characteristics. Proper technique and attention to environmental factors are vital in utilizing this rod effectively. As industries continue to evolve and face new challenges, the E7016 welding rod will remain an essential component in achieving durable, reliable welds. Whether in construction, oil and gas, or plumbing, the effectiveness of E7016 in pipe welding cannot be overstated. It represents a blend of engineering excellence and practical application, making it an indispensable tool in the hands of skilled welders.

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025

-

Premium Solid MIG Welding Wire - Strong, Low-Spatter WeldsNewsJul.21,2025

-

E71T-GS Self-Shielding Welding Wire | Gasless Outdoor UseNewsJul.20,2025

-

E312 Welding Electrode - High Corrosion Resistance & All-Purpose UseNewsJul.20,2025