welding wire 1.2mm manufacturer

The Importance of Choosing the Right 1.2mm Welding Wire Manufacturer

When it comes to welding, the choice of materials is critical to achieving high-quality and durable welds. Among these materials, welding wire plays a significant role. Specifically, 1.2mm welding wire is commonly used in various welding applications, and selecting a reliable manufacturer is of utmost importance. This article explores the significance of choosing a reputable 1.2mm welding wire manufacturer and the factors that should guide your decision.

Understanding 1.2mm Welding Wire

1.2mm welding wire is typically used for MIG (Metal Inert Gas) welding, a popular welding process known for its speed and efficiency. This diameter is suitable for a range of applications, including automotive, construction, and fabrication. The thickness of the wire directly affects the heat input and the penetration of the weld, making the choice of diameter crucial depending on the job at hand.

Quality Assurance

One of the foremost reasons to choose a reputable manufacturer is quality assurance. High-quality welding wire ensures a consistent feed, excellent arc stability, and minimal spatter, which are essential for producing strong and aesthetically pleasing welds. A reputable manufacturer will adhere to stringent quality control measures and industry standards, resulting in reliable products that meet the needs of professional welders.

Material Composition

The composition of the welding wire is another critical factor to consider. Different applications may require specific alloys or coatings to optimize performance and corrosion resistance. A reliable manufacturer will provide detailed information about the materials used in their 1.2mm welding wire, including compliance with relevant standards such as AWS (American Welding Society) specifications.

welding wire 1.2mm manufacturer

Availability of Varieties

Welding projects can vary widely in requirements, and a good manufacturer will offer various types of 1.2mm welding wire to cater to different needs. This includes solid wires, flux-cored wires, and stainless steel wires. Having a range of products allows welders to choose the most appropriate wire for their specific applications, enhancing efficiency and effectiveness on the job.

Customer Support and Service

Choosing a manufacturer that offers excellent customer support is vital. From providing technical advice regarding the best welding wire for specific tasks to assisting with product selection, good customer service can enhance the overall experience for welders. A manufacturer that values its customers will likely be more invested in delivering high-quality products and support.

Pricing and Value

While cost should not be the only consideration, it is essential to weigh the price of welding wire against its quality. Low-cost options may save money upfront but can lead to poor weld quality and higher long-term costs due to rework and additional material use. Therefore, it is essential to find a manufacturer that strikes a balance between affordability and quality.

Conclusion

In conclusion, selecting the right 1.2mm welding wire manufacturer is crucial for achieving high-quality welds in various applications. Emphasizing quality assurance, material composition, product variety, customer support, and value will enhance your welding experience and results. By investing time in choosing a reliable manufacturer, welders can ensure that their projects meet the highest standards of excellence and durability. With the right materials in hand, the possibilities for successful welding are limitless.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

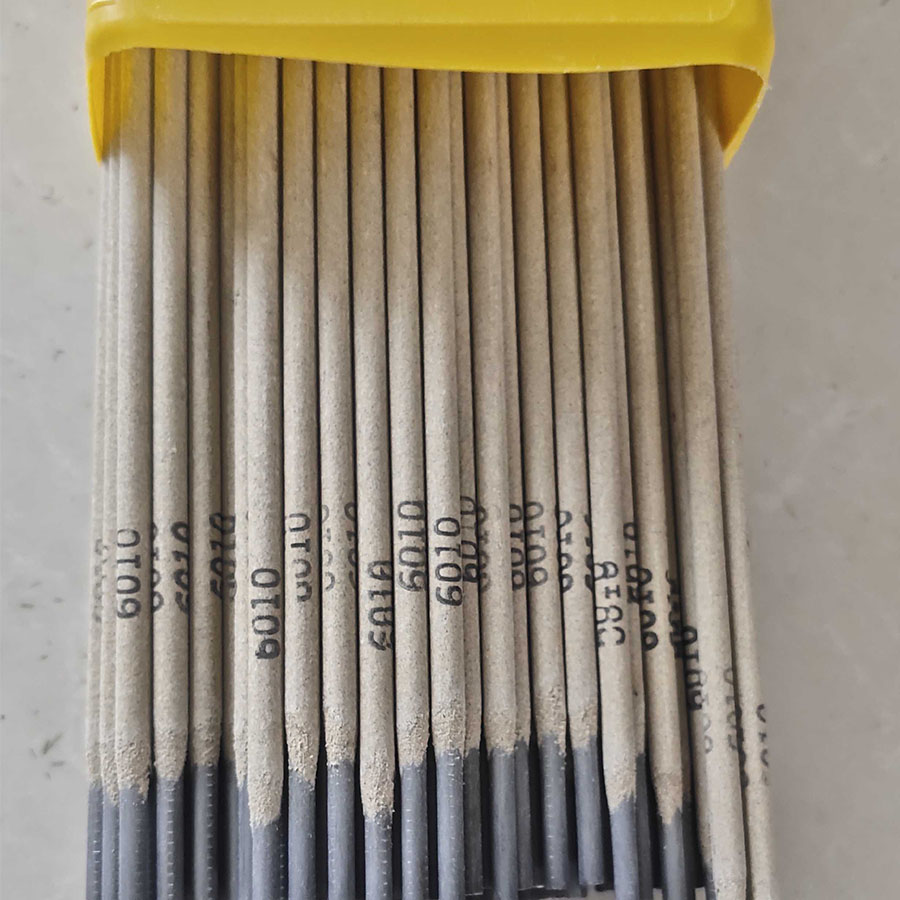

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025