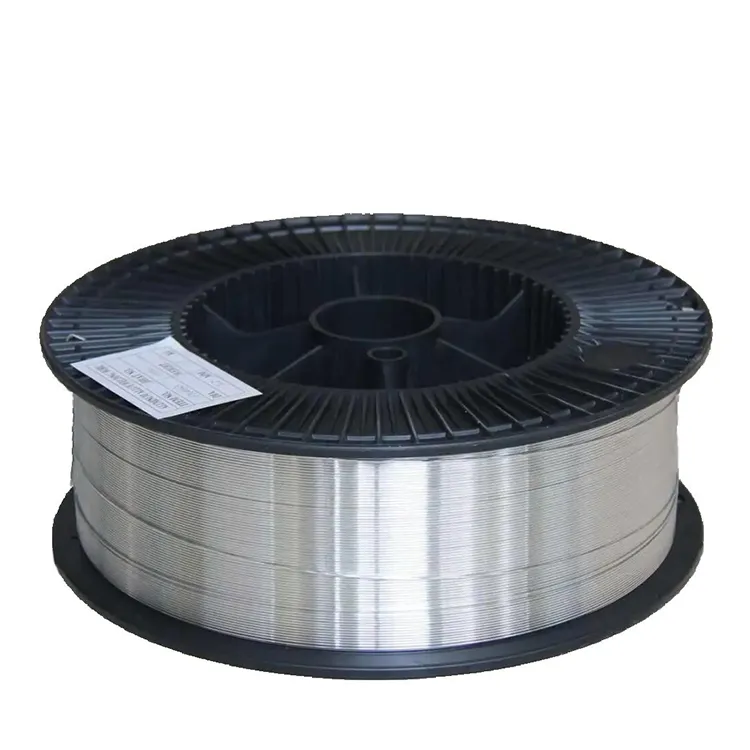

wholesale er70s welding wire manufacturer

The Importance of Wholesale ER70S Welding Wire Manufacturers

In the realm of metal fabrication and construction, the choice of materials plays a crucial role in ensuring the quality and longevity of the final product. Among these materials, welding wire stands out as a fundamental component, particularly ER70S welding wire. This type of wire is widely recognized for its versatility and effectiveness in various welding processes, making it a popular choice among professionals in the industry. As the demand for ER70S welding wire continues to grow, the role of wholesale manufacturers has become increasingly significant.

Understanding ER70S Welding Wire

ER70S welding wire is a type of filler material used in the Gas Metal Arc Welding (GMAW) process. The designation ER stands for electrode rod, while the number 70 indicates the wire's minimum yield strength, measured in thousands of pounds per square inch (psi). Specifically, ER70S welding wire has a yield strength of 70,000 psi, making it suitable for a range of applications—from structural steel to automotive manufacturing.

One of the key advantages of ER70S welding wire is its ease of use. It is designed to provide a smooth arc and excellent wetting characteristics, ensuring strong and reliable welds. Furthermore, this type of wire can be used with various shielding gases, allowing for flexibility in welding operations. Its composition typically includes iron, manganese, silicon, and small amounts of other elements, which contribute to its performance and durability.

The Role of Wholesale Manufacturers

Wholesale ER70S welding wire manufacturers play an essential role in the supply chain, providing high-quality products to distributors, retailers, and ultimately, end users. These manufacturers benefit from economies of scale, enabling them to produce welding wire at competitive prices. By purchasing directly from wholesale manufacturers, buyers can access cost-effective options without compromising on quality.

wholesale er70s welding wire manufacturer

In addition to pricing advantages, wholesale manufacturers often offer a wider range of products. They can provide different diameters, spool sizes, and packaging options, catering to various needs and preferences. This flexibility is invaluable for businesses, as it allows them to select the best welding wire for their specific projects.

Moreover, reputable wholesale manufacturers place a strong emphasis on quality control. They adhere to strict industry standards and regulations to ensure that their products meet or exceed the expectations of their customers. By investing in testing and quality assurance, these manufacturers build trust and credibility within the market, enabling them to establish long-term relationships with their clients.

The Future of ER70S Welding Wire

As industries evolve and new technologies emerge, the demand for high-quality welding materials is poised to grow. With the rise of automated welding processes and an increasing focus on sustainable practices, wholesale ER70S welding wire manufacturers must adapt to meet the changing needs of their customers.

Moreover, advancements in production techniques and materials science may lead to innovations in welding wire formulations. Manufacturers that stay ahead of these trends will be better positioned to provide superior products that enhance welding efficiency and effectiveness.

Conclusion

Wholesale ER70S welding wire manufacturers play a pivotal role in the welding supply chain, providing essential materials that contribute to the success of various projects. By understanding the importance of these manufacturers and the benefits they offer, businesses can make informed decisions when sourcing welding wire. Ultimately, the collaboration between manufacturers and their clients fosters innovation and quality in the welding industry, paving the way for a stronger future in metal fabrication.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025